Why Asphalt Needs Layers to Last

Published on: February 20, 2026 | Last Updated: April 14, 2025

Written By: George Voss

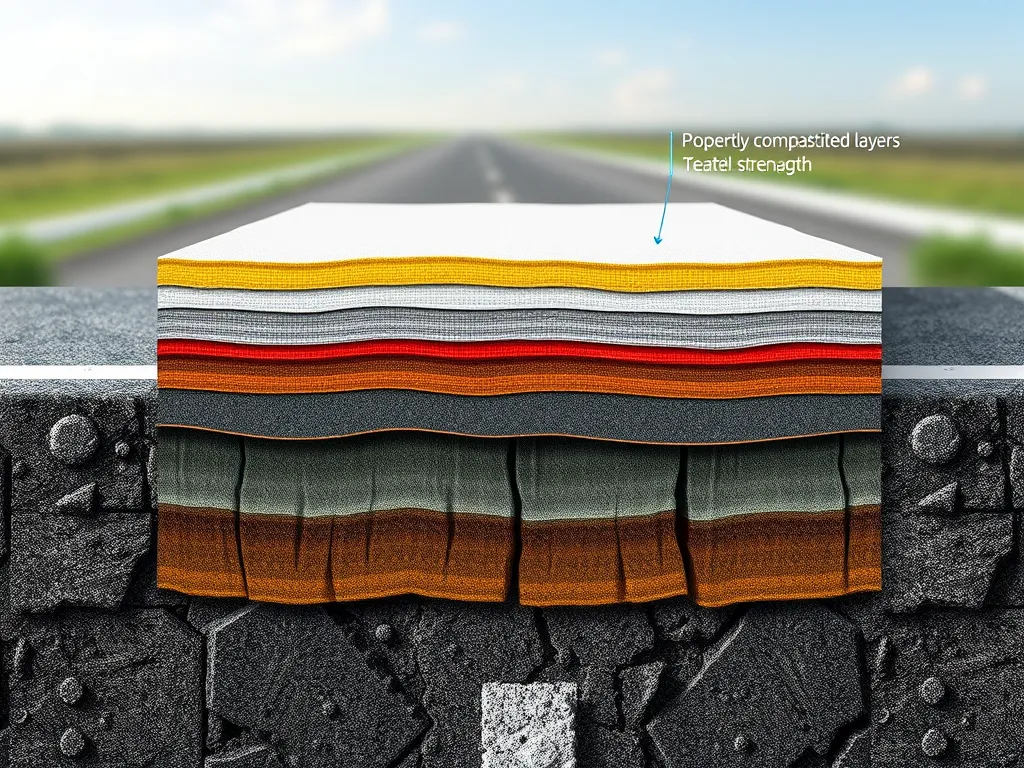

Asphalt pavement gets its strength from multiple compacted layers, each designed to handle specific stresses and environmental conditions. This layered system combines a weather-resistant surface, a flexible binder course, and a sturdy base layer to distribute vehicle weights, resist cracking, and prevent water damage. Proper layer construction increases pavement lifespan from 7-15 years for thin surfaces to 20+ years for engineered roads.

This article explains how asphalt layers work together like a team. You’ll learn why single-layer paving fails faster, how thickness choices affect rutting, and why highway layers differ from driveway designs. We break down material specs, compaction targets, and overlay techniques used by professionals. Real-world examples show how layered asphalt handles everything from frost heave to semi-truck traffic.

Contents

- Why Asphalt Pavement is Constructed in Layers

- Core Functions Of Asphalt Pavement Layers

- Critical Factors in Asphalt Layer Durability

- Asphalt Overlay: Purpose and Advantages

- Technical Considerations for Durable Layers

- Environmental Benefits Of Proper Layering

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

Why Asphalt Pavement is Constructed in Layers

Multi-layer construction forms asphalt’s backbone. This approach tackles varying stress types, climate impacts, and traffic loads through distinct material compositions. A typical road contains 3-5 layers, with costs ranging from $3-$7 per square foot depending on depth and mix design.

Structural Integrity Through Multi-layer Design

Asphalt layers work as a unit. High-grade PG 64-22 bitumen binds surface aggregates, while mid-layers mix coarser stones with modified liquid asphalt. Base layers often contain 6-inch thick compacted crushed rock. This tiered system allows upward force dissipation – 70% of load impacts absorb in lower layers. NAPA specifies minimum compaction of 92% density for lasting bonds between strata.

Role Of Load Distribution Across Asphalt Layers

A 40,000-pound truck tire applies 100-150 psi pressure. Surface layers handle abrasion, binder layers transfer weight sideways, and base layers spread loads across subgrade soil. Properly built roads cut subgrade stress by 80% compared to single-layer paving. Thick bituminous layers (4-6 inches) prevent rutting – a 1% increase in air voids drops shear strength by 15%.

Moving past load mechanics, asphalt’s stratified build serves distinct functions at each level. Upcoming parts break down how surfacing, binding, and base strata collaborate for long-lasting roads.

Core Functions Of Asphalt Pavement Layers

Every asphalt layer serves a unique purpose, working together to create roads that last decades. Proper asphalt layering transforms individual materials into a unified system capable of handling traffic, weather, and time.

Surface Layer: Weatherproofing and Wear Resistance

The top 1.5–2 inches (38–51 mm) use dense-graded mixes with performance-graded (PG) asphalt binders. This layer deflects water, blocks UV rays, and resists tire abrasion. Polymer-modified bitumen in high-traffic areas boosts crack resistance by 40% compared to standard mixes. Aggregates like granite or slag provide skid resistance, critical for safety during rain or snow.

Binder Layer: Stress Absorption &Amp; Stability

Beneath the surface lies the 3–4 inch (76–102 mm) binder course, engineered to handle shear stress from turning vehicles and braking forces. Stone-matrix asphalt (SMA) mixes here prevent rutting under loads exceeding 20,000 pounds per axle. The binder’s higher asphalt content (5.5–6.5%) acts as a shock absorber, reducing cracks from reaching the surface.

Base Layer: Foundation for Load-bearing Capacity

The deepest layer (4–12+ inches) uses open-graded aggregates like crushed limestone to support 80% of pavement loads. Proper compaction to 96% density (per AASHTO T 180) prevents settlement. Geotextile fabrics in weak subgrades add tensile strength, increasing load capacity by 300%. This layer also channels water away, preventing frost heave in freeze-thaw cycles.

While layer functions define the system’s backbone, material selection and installation precision determine its lifespan. Up next: how thickness, stiffness, and temperature tolerance keep these layers performing for 20+ years.

Critical Factors in Asphalt Layer Durability

Long-lasting pavements start with smart structural planning. Thickness, material choice, and climate adaptation form a triad that dictates how asphalt layers hold up against traffic and time.

Optimal Bituminous Layer Thickness Requirements

Bituminous layer thickness directly impacts load-carrying capacity. National Asphalt Pavement Association (NAPA) standards call for 2-4 inches in surface layers, with base layers hitting 6-8 inches for highways. A thin layer cracks; a thick one wastes funds.

Impact of Layer Thickness on Rutting Prevention

Rutting—those wavy grooves in pavements—drops by 95% when layers hit target depths. Thicker binder layers (1.5-2.5 inches) spread truck axle loads, cutting rut risk. Data shows 3-inch surfaces last 50% longer than 2-inch ones under 1,000+ daily trucks.

| Traffic Type | Surface Layer | Base Layer |

|---|---|---|

| Local Roads | 1.5-2″ | 4-6″ |

| Highways | 3-4″ | 8-12″ |

Material Stiffness and Shear Stress Resistance

Stiffness fights shear stress—the sideways forces that split pavements. PG 64-22 binders (common in warm zones) add flexibility. High-density aggregates boost stability, with 1.45-ton/cubic yard mixes stopping layer slippage.

Temperature Effects on Layer Performance

Hot climates demand layers that won’t soften past 140°F. In frost zones, thermal cracking starts when temps dip below 14°F. Superpave mixes (graded for local weather) adjust binder ratios—5.5% bitumen in Phoenix vs 6.2% in Minneapolis—to maintain layer cohesion.

Asphalt’s multi-layer system acts as armor against both traffic and climate. This structural logic also informs how crews apply fresh asphalt over old—a process we’ll unpack next.

Also See: How to Plan and Design Asphalt Parking Lots

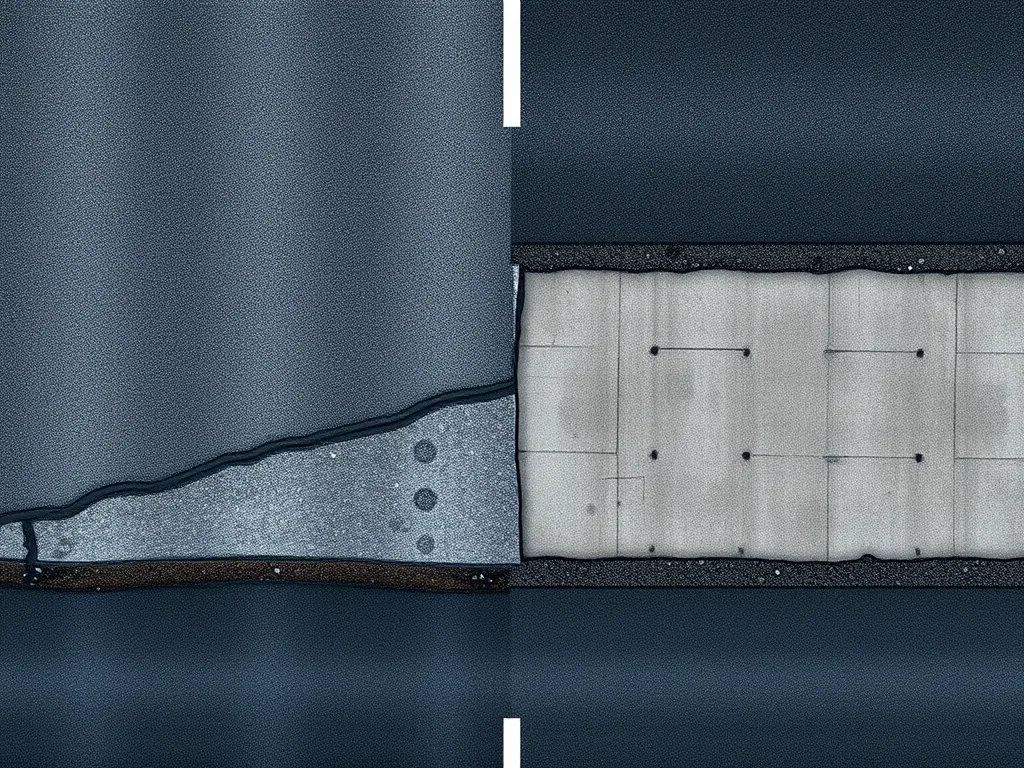

Asphalt Overlay: Purpose and Advantages

Adding fresh asphalt layers over worn roads boosts strength and cuts repair costs. This method skips full tear-outs, saving time and cash while boosting road life.

Extending Pavement Life Through Strategic Layering

Overlays add 2-3 inches of hot mix asphalt (HMA) to shield old layers from wear. Proper bituminous layer thickness stops cracks, ruts, and water harm. Roads with overlays last 8-15 years longer, slashing upkeep costs by up to 40%.

Bonding Between Existing and New Asphalt Layers

A tack coat—thin asphalt emulsion—glues old and new layers. This bond spreads weight evenly and stops slips. Tests show strong bonds raise shear strength by 60%, blocking cracks at the seam. Poor bonding cuts overlay life in half.

Up next: How to hit key specs for rock-solid layers. We break down compaction tricks and layer rules for light vs heavy traffic.

Technical Considerations for Durable Layers

Building long-lasting roads requires strict focus on two factors: how tightly asphalt is packed and how thick it’s poured. Both directly impact how long pavement holds up under traffic and weather.

Compaction Quality and Density Requirements

Pressing asphalt mix isn’t enough—it must hit 92-96% density to lock out water and stop cracks. Steel-wheel rollers apply 8-12 tons of force during paving to crush air voids below 7%. Miss this target, and rain slips in, freezing cracks widen, and potholes form within months. For high-traffic zones, nuclear density gauges verify each layer meets specs before adding the next.

Layer Thickness Specifications by Traffic Type

A parking lot won’t carry the same load as a highway. Cars need 3-inch surface layers, while truck routes demand 6-8 inches. Thin layers under heavy rigs split like plywood; thick layers on low-traffic roads waste funds. NAPA’s 1996 manual sets clear rules: aggregate size must match layer depth, and binder grades must suit local climate. A 1.5-inch base course works for driveways, but interstates need 12-inch compacted bases with crushed stone.

National Asphalt Pavement Association Guidelines

NAPA’s standards tie traffic volume to bituminous layer thickness. Roads with 1,000+ trucks daily require 4-inch surface layers using PG 76-22 binder. Suburban streets use 2.5-inch layers with PG 64-28. Following these specs cuts rutting by 60% and boosts road life past 15 years. Mix designs also factor in regional temps—softer binders in cold areas, stiffer in hot zones—to stop layers from cracking or squishing.

Getting compaction and thickness right isn’t just about strength—it’s about smart resource use. Up next: how proper layering slashes waste and supports sustainability.

Environmental Benefits Of Proper Layering

Multi-layer construction does more than boost pavement strength—it directly supports eco-friendly building practices. Strategic design cuts resource use while extending service life, creating ripple effects through reduced energy consumption.

Reduced Material Waste Through Layer Optimization

Precision engineering ensures each bituminous layer thickness meets exact needs without overbuilding. National Asphalt Pavement Association data shows optimized designs lower material use by 18-22% versus single-layer methods. Recycling enters the equation through reclaimed asphalt pavement (RAP), with modern mixes incorporating 20-30% recycled content without compromising structural integrity.

Long-term Sustainability Of Layered Pavements

Properly built roads with distinct surface, binder, and base layers survive 15-20 years before major repairs—twice the lifespan of poorly constructed alternatives. This longevity cuts emissions tied to frequent reconstruction. One mile of preserved pavement prevents 25 tons of CO2 emissions from construction equipment. Newer techniques like porous pavements with open-graded surface layers manage stormwater while reducing urban heat retention by 7-10°F.

These ecological gains set the stage for exploring precise engineering standards governing layer performance.

Frequently Asked Questions

Why Can’t Asphalt Be Poured in Single Layers?

Paving asphalt in a single layer does not provide the necessary structural integrity or load distribution, leading to rapid deterioration under stress. Single-layer systems cannot effectively manage the varied demands from traffic loads and environmental factors, resulting in cracking, rutting, and ultimately, a shortened pavement lifespan.

How Often Should Asphalt Overlays Be Applied?

The frequency of asphalt overlays depends on traffic volume, environmental conditions, and the wear observed on the pavement. Generally, overlays can be applied every 8 to 15 years, as they serve to prolong the life of the existing pavement by reducing wear and protecting underlying layers from moisture and stress. Regular inspections will help determine the best timing for application.

What Are the Environmental Benefits Of Proper Layering?

Proper layering in asphalt construction significantly reduces material waste by optimizing the thickness and performance of each layer. This optimization decreases resource use, while techniques like incorporating recycled asphalt pavement (RAP) can further enhance sustainability. Well-layered pavements have longer lifespans, resulting in fewer repairs and lower emissions related to construction activities.

How Does Temperature Affect Asphalt Layer Durability?

Temperature fluctuations can impact asphalt layer performance; in hot climates, layers must withstand softening beyond certain thresholds, while in cold regions, extreme temperatures can lead to cracking. Utilizing graded mixes designed for local weather conditions can mitigate these effects, ensuring that asphalt layers maintain their integrity across varying environmental conditions.

What Role Does Compaction Play in Asphalt Layer Durability?

Compaction is critical for the durability of asphalt layers, as properly compacted layers improve density, reduce water infiltration, and minimize the formation of voids. Achieving optimal compaction (typically around 92-96% density) prevents premature failures and extends the overall lifespan of the pavement.

Closing Thoughts

Layering is the backbone of asphalt durability. Each layer—from surface to base—plays a vital role. The surface layer enhances weather resistance and wear performance. The binder layer absorbs stress and ensures stability. The base layer provides essential load-bearing capacity.

Careful consideration of thickness and material quality significantly impacts performance. Optimal layering helps prevent rutting and enhances overall lifespan. Plus, incorporating proper layering techniques supports environmental sustainability by reducing waste.

Ultimately, investing in a multi-layer asphalt design translates to long-term cost savings and efficiency. For more detailed insights, check out Asphalt Calculator USA.

Additional Resources for You:

- Lavin, P. (2003). Asphalt Pavements: A Practical Guide to Design, Production, and Maintenance for Engineers and Architects. London: Taylor & Francis.

- Laying of all Asphalt Courses in One Step – ScienceDirect

- Flexible Pavement: Layers, Components, and Advantages