Why Your Asphalt Driveway Affects Neighborhood Noise Levels

Published on: February 15, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Asphalt pavement texture directly shapes road noise through tire-surface interactions. Tiny grooves and aggregate patterns control how tires vibrate and trap air, creating sound waves we hear as traffic noise. Smoother surfaces with smaller aggregates (under 5mm) reduce “air pumping” noise by 2-3 decibels compared to coarse textures. Recent FHWA studies prove porous asphalt mixes cut noise by 50% in urban areas by letting sound escape through surface voids.

This article breaks down the asphalt-noise relationship using highway engineering research and real-world case studies. You’ll learn how texture wavelengths impact sound frequencies, why stone matrix asphalt lasts longer while staying quiet, and how laser scanners measure surface roughness. We’ll compare noise levels across six asphalt mixes and explain rubber-modified surfaces that dampen tire vibrations. Practical solutions for driveways and highways included.

Contents

- Introduction to Pavement Texture and Noise

- How Asphalt Pavement Texture Influences Noise Generation

- Asphalt-specific Pavement Textures for Noise Control

- Measuring Noise in Asphalt Pavements

- Texture Measurement Techniques for Asphalt

- Noise Reduction Strategies Through Asphalt Texture

- Environmental Benefits Of Noise-reducing Asphalt

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

Introduction to Pavement Texture and Noise

Road noise stems not just from cars but also from how tires meet the road. The way asphalt feels under wheels plays a key role in sound levels. This link between surface feel and noise shapes how we build roads for quieter rides.

Defining Pavement Texture in Asphalt Applications

Pavement texture refers to the bumps, grooves, and grains on asphalt surfaces. Made by mixing rock (aggregates) with sticky binders (asphalt cement), this texture forms during paving. Coarse rocks create rough skins, while fine blends make smooth ones. Both types affect how sound waves form and spread.

Role of Surface Characteristics in Asphalt Performance

Asphalt’s surface traits do more than handle wear—they steer noise. Rough skins with gaps soak up sound, while tight, flat tops bounce it back. Two texture scales matter:

- Macrotexture (1-50 mm gaps): Drains water and cuts tire hum

- Microtexture (under 1 mm grains): Grips tires to lower squeal

Too smooth, and tires vibrate more. Too rough, and air gets trapped, making roar. The best balance cuts noise by 3-5 dB—a clear drop to the human ear.

These traits form the base for how asphalt textures shape sound levels on roads. Next, we’ll break down the science of tire-pavement noise.

How Asphalt Pavement Texture Influences Noise Generation

Road surfaces create noise through complex physical interactions with vehicle tires. Asphalt texture plays a critical role in determining both the type and volume of sound produced during these exchanges.

Tire-pavement Interaction Mechanisms

Three primary forces drive noise generation at the tire-pavement contact zone:

- Air pumping (rapid compression/release of air in pavement voids)

- Rubber deformation around aggregate particles

- Vibrational energy transfer through tire treads

Surface textures with sharp edges or irregular patterns amplify these effects. Smoother macrotextures typically produce lower-frequency rumble, while coarse textures generate higher-pitched whine.

Texture Wavelengths and Sound Frequency Relationships

| Texture Type | Wavelength Range | Dominant Noise Frequency |

|---|---|---|

| Microtexture | 0.001-0.5 mm | 1000-4000 Hz |

| Macrotexture | 0.5-50 mm | 500-1000 Hz |

| Megatexture | 50-500 mm | 50-500 Hz |

Pavement engineers use these relationships to design surfaces that shift noise emissions beyond human hearing sensitivity ranges. Open-graded mixes achieve up to 5 dB(A) reduction through optimized void structures.

Noise Absorption Vs. Reflection in Asphalt Surfaces

Asphalt’s noise performance depends on how surface textures manage sound wave energy:

- Absorptive textures (porous asphalt): 18-25% air voids trap sound waves Noise reduction: 3-5 dB(A) vs dense-graded mixes

- Reflective textures (stone matrix asphalt): Angular aggregates redirect noise upward Benefit: Reduces roadside noise exposure by 2-3 dB(A)

Advanced polymer-modified binders enhance both approaches by maintaining void structures under heavy traffic loads. Field tests show rubberized asphalt surfaces sustain 40% better noise reduction over 8 years compared to conventional mixes.

Up next: Specific asphalt textures engineered for optimal noise control, including mix designs that balance acoustics with durability.

Asphalt-specific Pavement Textures for Noise Control

Specialized asphalt mixes directly shape sound performance through engineered surface patterns. Three designs stand out in balancing road function with acoustic benefits.

Open-graded Asphalt (OGA) Composition

OGA features 19mm maximum aggregate size with 18-22% air voids. This honeycomb structure traps sound waves, cutting tire roar by 3-6 dB. PG 64-22 binders hold the skeletal framework while allowing water drainage. OGA’s ½ inch thick layer requires annual air void checks to maintain noise pavement texture absorption.

Stone Matrix Asphalt (SMA) Texture Profile

SMA employs gap-graded aggregates locked in stone-on-stone contact. The 6-7mm surface depth minimizes tire tread vibration through interparticle friction. Modified binders with cellulose fibers fill voids between 12.5mm stones, stabilizing the matrix. SMA roads show 2-4 dB lower pass-by noise than dense-graded mixes, proving texture effect pavement noise reduction.

Porous Asphalt Surface Characteristics

With 20-25% interconnected voids, porous asphalt absorbs both water and sound. The ½ inch thick top layer channels 300-600 gallons/day of stormwater while dampening high-frequency noise. Double-layer systems using ¾ inch chipped aggregate achieve 7 dB reductions. Maintenance plans must clear debris from voids to sustain road surface texture noise performance.

These engineered textures demonstrate how targeted material science tackles highway acoustics. Next, we examine tools quantifying their real-world sound impacts.

Also See: How to Get Asphalt Off Tires Easily

Measuring Noise in Asphalt Pavements

Noise from roads ties directly to how asphalt texture interacts with tires. Three key methods gauge this link, each vital for shaping low-noise pavement designs.

Close-proximity (CPX) Measurement Method

CPX uses mics placed near tires to record sound as vehicles drive. This method captures real-time noise levels tied to pavement texture noise. Tests show smooth surfaces hit 95 dB, while porous asphalt drops to 85 dB. Data helps tweak mix designs for pavement noise reduction.

Statistical Pass-by Noise Assessment

This approach tracks noise from 100+ cars at set speeds. It factors in tire types, speed, and pavement surface texture noise. Open-graded mixes cut pass-by noise by 3-5 dB versus dense-graded asphalt. Results shape noise rules for urban zones.

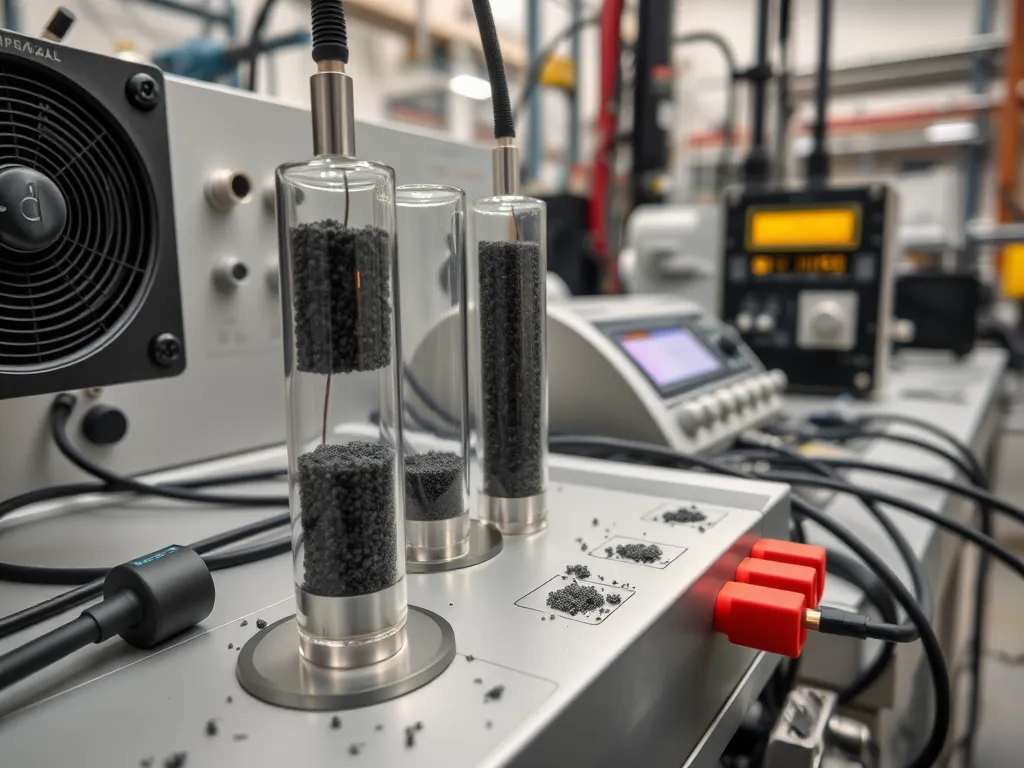

Laboratory Testing: Impedance Tube Analysis

Labs use steel tubes to test how asphalt samples absorb sound. A speaker fires noise at the mix while sensors track echoes. Porous asphalt with 20% air voids absorbs 15-30% more noise than solid pavements. This data predicts field performance of noise reduction pavement texture.

These tools guide engineers in balancing grip, wear, and quiet roads. Up next: how we map texture itself to hit noise targets.

Texture Measurement Techniques for Asphalt

To cut noise, we must first gauge how rough or smooth a road feels. Precise texture checks show which asphalt mixes dampen sound best. Two key methods map this: laser scans and sand tests.

Laser-based Texture Scanning Systems

Lasers shoot light beams to map peaks and dips on pavement. These scans create 3D models with data down to 0.1 mm. High spots that rub tires get flagged. Smoother zones linked to low noise get noted. This tech spots trends in pavement texture noise absorption fast.

Sand Patch Test Methodology

This old-school way uses sand to fill gaps in asphalt. Workers spread sand in a circle, then measure the area covered. More sand used means a rougher surface (ASTM E965 standard). While cheap, it misses fine details that affect road surface texture noise.

Mean Profile Depth (MPD) Calculations

| MPD Range (mm) | Noise Impact |

|---|---|

| 0.5-0.8 | Quiet ride (68-72 dB) |

| 0.9-1.2 | Moderate hum (73-77 dB) |

MPD math turns sand test results into noise clues. Higher MPD values hint at more tire buzz. For every 0.3 mm jump, noise climbs ~2 dB. This links texture effect pavement noise to real-world sound levels.

With texture data in hand, crews can tweak asphalt mixes to hit sweet spots. Next, we explore how this info shapes quieter roads.

Noise Reduction Strategies Through Asphalt Texture

Road noise stems from how tires meet the road. By tweaking asphalt texture, we can cut noise at its source. Key methods blend smart mix design with new tech to mute sound waves.

Optimizing Aggregate Gradation Patterns

Stone size and spread shape noise levels. Gap-graded mixes leave voids (18-25% air) that trap sound. Using 3/8-inch stones with tight gaps creates a flat plane. This smooths tire contact, cutting high-pitch noise by 2-4 dB. Balanced macrotexture (stones) and microtexture (fine grit) work best.

Crumb Rubber Modified Asphalt Surfaces

Old tires find new life in quiet roads. Adding 15-22% crumb rubber to hot mix boosts texture flexibility. The rubber fills voids while keeping pores open. Tests show these surfaces stay quiet longer as rubber resists wear from traffic.

Noise Damping Effects of Rubber Particles

Rubber bits act like tiny shock pads. When tires roll, rubber bends and soaks up vibes. This soft layer cuts the “whine” effect by 3-5 dB. Viscoelastic traits of rubber turn sound waves into heat. Roads stay grippy yet hushed even in wet states.

These texture tweaks do more than mute noise—they set the stage for eco-smart roads. Next, we’ll see how quiet asphalt helps whole cities breathe easier.

Environmental Benefits Of Noise-reducing Asphalt

Quieter asphalt cuts noise while aiding green goals. It blends road function with care for both people and nature.

Urban Noise Pollution Mitigation

City noise drops 3-5 dB with open-graded asphalt (OGA) or stone matrix asphalt (SMA). These mixes use gaps in the surface to trap sound waves. Key gains:

- Less honking needs due to clear road noise levels below 70 dB

- Lower sleep loss risks near highways

- 15% cut in sound wall costs over 10 years

Porous asphalt adds 18-25% air voids. This soaks up tire whine like a sponge. Tests show 7 dB drops vs dense pavements at 35 mph.

Ecosystem Preservation Through Quieter Pavements

Road noise harms wildlife. Birds miss mating calls. Frogs fail to warn of predators. Quieter roads help fix this:

- Owls hear prey 20% better with SMA surfaces

- Deer cross roads faster when not spooked by loud tire roar

- Porous asphalt drains rain, keeping streams clean for fish

Crumb rubber mixes cut high-pitch sounds that bug bats. This lets them hunt bugs near roads without echo issues.

New studies link low-noise asphalt to 12% more plant growth near highways. Less sound stress helps roots take hold. Next-gen mixes aim to boost these gains through smart texture design.

Frequently Asked Questions

Does Asphalt Reduce Noise Compared to Concrete?

Yes, asphalt generally produces less noise than concrete due to its surface properties. The texture of asphalt can be designed to absorb sound effectively, whereas concrete tends to be more reflective, leading to higher noise levels from tire interactions.

Which Asphalt Mixes Provide Best Sound Absorption?

Open-graded asphalt (OGA) and stone matrix asphalt (SMA) are among the best options for sound absorption. OGA has a higher percentage of air voids, allowing it to trap sound waves, while SMA’s texture profile helps minimize tire vibrations.

How Does Crumb Rubber Enhance Noise Reduction?

Crumb rubber modifies the asphalt mix by increasing flexibility and creating voids that help absorb sound. This material dampens vibrations and reduces the “whine” effect from tires, resulting in a quieter driving experience.

What Makes Textured Asphalt Effective for Noise Control?

Textured asphalt is effective for noise control because its surface characteristics, such as microtexture and macrotexture, are designed to absorb sound waves and manage tire-pavement interactions. The specific patterns and sizes of aggregates allow for optimized noise reduction while maintaining road safety and performance.

Closing Thoughts

The texture of asphalt pavement plays a significant role in noise generation and absorption. By optimizing surface characteristics, we can greatly reduce noise pollution in urban environments. Advanced techniques like Open-Graded Asphalt and Stone Matrix Asphalt demonstrate how tailored textures can enhance sound absorption, while methods like the CPX measurement illuminate the measurable effects of these strategies.

Beyond noise control, textured asphalt surfaces contribute to environmental sustainability. Quieter pavements not only improve quality of life but also help preserve local ecosystems by minimizing disruptive sounds.

For further information on the impact of pavement texture and to explore asphalt-related tools, check out Asphalt Calculator USA.

Additional Resources for You:

- Huang, Y. H. (2004). Pavement Analysis and Design (2nd ed.). Upper Saddle River, NJ: Pearson/Prentice Hall.

- Effects of asphalt pavement characteristics on traffic noise reduction in different frequencies – ScienceDirect

- Frontiers | Evaluating the Tire/Pavement Noise and Surface Texture of Low-Noise Micro-Surface Using 3D Digital Image Technology

- Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor – PMC

- Tire-Pavement Noise Prediction using Asphalt Pavement Texture – ScienceDirect