How to Handle Large-scale Asphalt Driveway Repairs: A Step-by-step Guide

Published on: February 1, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Large-scale asphalt driveway repairs fix structural damage like deep cracks (over 1/4 inch wide), sunken areas, and clusters of potholes using industrial-grade materials and equipment. These projects differ from routine maintenance by requiring base layer corrections, heavy compaction tools like vibratory rollers, and precise slope adjustments to prevent water pooling. Key steps include evaluating load capacity (standard driveways handle 8,000-10,000 lbs), testing drainage pitch (1-2% slope recommended), and choosing between cold patch ($3-$5 per sq ft) or hot mix asphalt ($7-$12 per sq ft) based on climate and damage severity.

This article explains how to assess crumbling sections, repair 100+ sq ft areas, and decide between DIY or pro solutions. You’ll learn to identify base failures needing excavation, calculate material quantities for 20×20 ft driveways, and apply EPA-approved recycling methods. We’ll cover cost-saving overlays, proper edge sealing with polymer-modified binders, and safety protocols for operating plate compactors weighing 200+ lbs.

Contents

Assessing the Damage

Proper evaluation determines repair methods and material needs. Start by walking the driveway surface, noting visible defects and testing problem areas with basic tools like a screwdriver or straightedge.

Common Types Of Large-scale Asphalt Damage

Three primary issues plague aging driveways. Each requires distinct repair strategies to prevent further deterioration.

Deep Cracks and Seam Separation

Cracks wider than 1/4 inch signal structural trouble. Alligator cracking (interconnected web patterns) and longitudinal cracks along seams often indicate base layer failure. Water seeping through these gaps erodes the gravel foundation, accelerating pavement breakdown.

Extensive Potholes and Crumbling Areas

Potholes deeper than 2 inches demand immediate attention. These form when water penetrates surface cracks, freezes, and pushes asphalt upward. Heavy vehicles worsen weak spots, creating craters that can damage tires and trip hazards.

Sunken or Uneven Driveway Sections

Sags deeper than 1/2 inch suggest compromised subgrades. Poor soil compaction during installation or erosion from faulty drainage causes these dips. Uneven areas collect water, speeding asphalt decay through repeated freeze-thaw cycles.

Evaluating Structural Integrity

Test load-bearing capacity before committing to repair plans. Structural failures require full-depth fixes, while surface issues might need simpler patches.

How Much Weight Can an Asphalt Driveway Handle?

Standard residential driveways support 3,000-8,000 lbs per axle when built with 2.5-3 inches of asphalt over 6 inches of compacted aggregate. Check for rutting deeper than 1 inch under parked vehicles – a clear sign of overloading.

Identifying Soft Spots and Base Failures

Probe suspicious areas with a steel rod. If it sinks 3+ inches easily, the base has failed. Look for “pumping” – water/mud surfacing near cracks during weight tests. These zones require excavation down to stable soil.

Accurate damage assessment sets the stage for effective repair planning. Up next: gathering tools and materials tailored to your driveway’s needs.

Preparing for Asphalt Driveway Repairs

Proper groundwork sets the stage for lasting results with asphalt driveway repairs. Tackling large-scale projects demands strategic planning and precise material selection.

Essential Tools and Materials

Stockpile these items before starting asphalt driveway repairs: wheelbarrows, shovels, rakes, and a reliable temperature gauge. For structural fixes, keep tack coat spray or emulsion on hand to bond layers.

Asphalt Cold Patch vs Hot Mix Applications

Cold patch works for quick pothole repairs in any weather but lasts 1-3 years. Hot mix (applied at 275-325°F) forms permanent bonds for cracks wider than ½” or areas exceeding 3 sq ft. Expect to pay $2-$5 per square foot for hot mix versus $1-$3 for cold patch.

Compaction Equipment and Safety Gear

Use plate compactors (3,000-5,000 PSI) for uniform density. Wear ANSI-approved gloves, goggles, and steel-toe boots. For driveways over 30 ft long, rent vibratory rollers to handle extended surfaces efficiently.

Testing Drainage and Surface Stability

Waterlogged bases cause 60% of asphalt failures. Test drainage by pouring 5 gallons of water across the driveway – pooling within 30 minutes signals trouble.

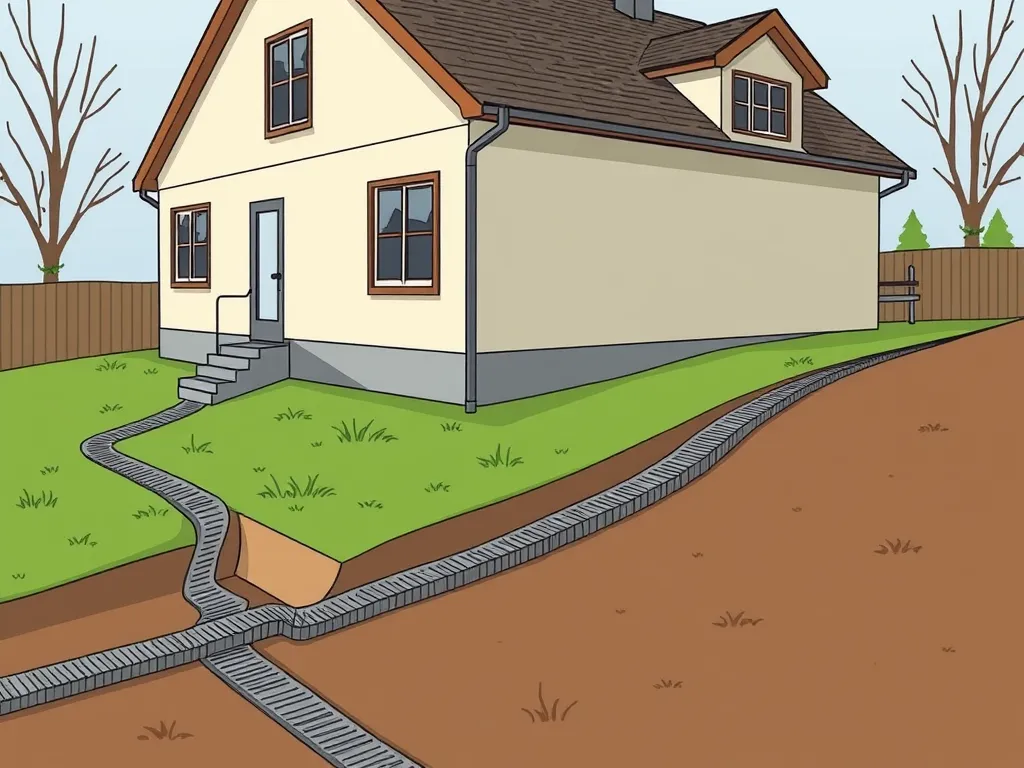

Fixing Drainage Issues Before Repairs

Install French drains ($10-$16 per linear foot) along edges or regrade slopes to maintain 2% pitch away from structures. Compact subsoil to 95% Proctor density using clay or crushed stone (R-value ≥ 78).

Solid foundations and proper materials pave the way for effective asphalt repair techniques. Next, we’ll break down step-by-step methods for restoring cracked or sunken surfaces.

Repair Techniques for Large-scale Damage

Effective asphalt driveway repairs demand methodical approaches for different damage types. Follow industry-tested methods to restore structural integrity and prevent future deterioration.

Repairing Extensive Cracks

Wide or interconnected cracks exceeding 1/4 inch require specialized treatment. Use PG 64-22 asphalt binder for optimal flexibility in temperature swings.

Step 1: Clean and Widen Damaged Areas

Remove vegetation and debris with a wire brush or air compressor. Widen cracks to 1-inch using a masonry chisel, creating vertical edges for better adhesion. Apply tack coat (ASPHALT EMULSION SS-1H) to exposed surfaces.

Step 2: Fill with High-Quality Asphalt Patch

Pour polymer-modified cold mix asphalt into cracks, overfilling by 1/2 inch. For gaps deeper than 2 inches, add aggregate base material first. Hot mix asphalt (HMA) at 300°F performs better for repairs exceeding 3 linear feet.

Step 3: Compact and Seal Repaired Sections

Use a 6-inch vibratory plate compactor to achieve 92% density. Seal edges with coal-tar emulsion sealant, applying 0.25 gallons per square yard. Allow 24-48 hours curing before vehicle traffic.

Fixing Large Potholes and Missing Chunks

Depressions deeper than 3 inches need layered repairs. Calculate material needs using the formula: (Depth in inches x Area in sq ft) ÷ 324 = Tons required.

Step 1: Remove Debris and Level the Base

Excavate loose material to stable subgrade. Test compaction with a dynamic cone penetrometer – readings below 4 inches/blow indicate proper base stability. Add 3/4″ crushed stone if needed.

Step 2: Layer and Compact Patch Material

Install patches in 2-inch lifts. Compact each layer with a 175-lb jumping jack compactor. For areas over 10 sq ft, use infrared asphalt heaters to bond new material at 275°F.

Step 3: Ensure Proper Edge Bonding

Bevel repair edges at 45-degree angles. Apply liquid asphalt binder (PG 58-28) to vertical surfaces. Roll perimeter with a 2-ton steel drum roller at 3 mph for seamless integration.

Can You Asphalt Over an Old Driveway?

Overlays work only when existing pavement has less than 25% surface damage. Conduct a PCI (Pavement Condition Index) assessment first.

When Overlay Repairs Are Appropriate

Resurface if base shows no heaving or washouts. Minimum overlay thickness: 1.5 inches for residential driveways. Use SAMI (Stress-Absorbing Membrane Interlayer) for crack reflection prevention.

Limitations of Resurfacing Damaged Bases

Overlays fail within 12-18 months if subgrade CBR (California Bearing Ratio) drops below 20. Address base failures with full-depth reclamation – pulverizing 6-8 inches of existing material before new installation.

With repair methods established, evaluating cost factors becomes critical for project planning. Material selection and labor logistics directly impact budgets for extensive driveway renovations.

Also See: Can You Pressure Wash Oil Stains Off Asphalt? Be Cautious

Cost Considerations for Asphalt Repairs

Managing expenses requires balancing material quality, labor needs, and project scope. Let’s break down what drives asphalt driveway repair costs.

Factors Affecting Repair Costs

Material and labor choices create the largest cost variables. Location, damage severity, and project size also play roles.

Material Choices and Quantity Estimates

Cold patch asphalt costs $2-$5 per square foot but lasts 1-3 years. Hot mix asphalt runs $4-$8 per square foot with 7-15 year durability. Recycled asphalt (RAP) cuts material costs by 20-30% but requires thicker layers. For deep cracks, polymer-modified sealants add $0.15-$0.30 per linear foot. Always add 10-15% extra material to account for compaction loss.

Labor vs DIY Expense Comparison

Contractors charge $45-$75 hourly for asphalt driveway repairs. Full-depth patching a 20×20 area typically takes 12-16 labor hours. DIY costs drop to $2-$4 per square foot but require renting a plate compactor ($90/day) and asphalt roller ($150/day). Errors in base preparation or compaction often lead to 30-50% higher long-term costs.

How Much Does a 20×20 Asphalt Driveway Cost?

A 400-square-foot driveway repair ranges from $1,200 to $2,800. Severe base damage can push costs to $4,500+.

Budgeting for Large-Scale Projects

Allocate 60% of funds to materials, 30% to labor, and 10% for equipment/permits. For overlays, calculate 2.5 tons of asphalt per inch thickness per 100 square feet. Include $300-$600 for subbase repairs if fixing sunken areas. Many municipalities require stormwater management plans for projects exceeding 500 square feet – factor in $200-$500 for drainage upgrades.

With cost factors mapped, let’s explore when to tackle repairs yourself versus hiring pros.

DIY Vs Professional Asphalt Repairs

Home fixes save cash but have limits. Big jobs need pros with gear and know-how. Size, depth, and base health decide your path.

When to Handle Repairs at Home

Tackle small tasks if you have time and basic tools. Focus on surface flaws that won’t spread if fixed right.

Projects Suitable for DIY Asphalt Repair

Use cold patch for holes under 2 inches deep. Seal hairline cracks with rubber fill. Fix edge chips with trowel-grade mix. Spread seal coat every 3-5 years. These steps buy time but won’t fix base flaws.

When to Call a Professional Contractor

Pros handle structural threats you can’t see. They spot weak bases, fix drainage traps, and use gear like 2-ton rollers.

Signs You Need Expert Intervention

Cracks wider than your thumb need heat guns. Sinking spots hint at soil washouts. Alligator cracks mean base rot. Multi-hole zones require full tear-outs. Pros test load strength (8,000+ lbs per axle) and regrade slopes.

Up next: Learn eco-friendly ways to care for your asphalt while keeping costs low.

Environmental Considerations

Large-scale asphalt repairs impact local ecosystems. Smart practices minimize harm while maintaining durable results.

Eco-friendly Asphalt Maintenance Practices

Modern techniques reduce environmental footprints without sacrificing performance. Contractors now prioritize three key areas:

Recycling Old Asphalt Materials

Reclaimed asphalt pavement (RAP) gets new life through milling and reprocessing. The Federal Highway Administration reports 90 million tons of RAP reused annually in US road projects. For driveways, recycled asphalt costs 30% less than virgin material and handles temperatures from -20°F to 120°F when mixed with fresh PG 64-22 binder.

| Material | Recycled Content | Cost/Ton |

|---|---|---|

| Virgin Hot Mix | 0% | $85-$110 |

| 50% RAP Mix | 50% | $60-$75 |

Using Sustainable Sealants

Low-VOC coal tar alternatives now dominate the market. Soybean-based sealants like BioSpan® cut hydrocarbon emissions by 65% compared to traditional options. These products cure faster (2-3 hours vs 24 hours) and withstand 300+ freeze-thaw cycles without cracking.

Proper drainage planning prevents sealant runoff into waterways. Install filter fabric under repaired areas to capture particulates. Slope grades at 2% minimum to direct water toward containment systems.

Up next: Balancing eco-friendly repairs with budget realities requires smart cost analysis.

FAQ: Large-scale Asphalt Driveway Repairs

How Do You Repair a Badly Damaged Asphalt Driveway?

To repair a badly damaged asphalt driveway, assess the extent of damage first. You may need to fix deep cracks, fill large potholes, or address sunken areas. For extensive repairs, cleaning the area, applying appropriate patch materials, compacting, and sealing the surface are crucial steps. Always ensure proper drainage to prevent future issues.

How to Handle Large-scale Repairs at Home?

For homeowners looking to tackle large-scale asphalt repairs, it’s essential to have the right tools and materials, assess the damage accurately, and apply appropriate repair techniques. Focus on manageable areas, use cold patch for temporary fixes, and consider professional help for structural issues. Proper planning and safety precautions will lead to better results.

Closing Thoughts

Handling large-scale asphalt driveway repairs requires careful assessment and planning. From identifying damage types to evaluating structural integrity, every step is vital for successful outcomes. Choosing the right materials and techniques ensures durability. Additionally, weigh the benefits of DIY against hiring professionals based on project scope and complexity.

Remember, factor in costs related to materials and labor. Staying informed helps you budget effectively. Don’t overlook environmental considerations, like recycling old asphalt and using sustainable products, to minimize impact.

For more information and resources on asphalt projects, visit Asphalt Calculator USA. Equip yourself with the knowledge necessary for top-notch driveway repairs.