How to Choose the Right Sealcoating Equipment

Published on: January 23, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Choosing the right sealcoating equipment requires matching your project size with machine capacity, selecting durable materials like steel or poly tanks, and prioritizing features like adjustable spray wands or tow-behind systems. Project scope determines whether a 50-gallon handheld sprayer or a 500-gallon truck-mounted unit works best. Pump pressure (aim for 150-250 PSI), nozzle type (fan vs. stream), and corrosion-resistant parts directly impact application quality and long-term costs.

This guide breaks down key factors: tank size for residential driveways vs. parking lots, sprayer mobility on uneven terrain, and maintenance routines to avoid clogged pumps. Learn how spray width settings affect coverage rates, why viscosity matters for sealer types, and budget-friendly options under $1,500 versus commercial-grade systems exceeding $10,000. We’ll cover equipment lifespan, eco-friendly practices, and avoiding common mistakes like overspray or under-mixing aggregates.

Contents

- Understanding Sealcoating for Asphalt Maintenance

- Key Factors in Sealcoating Equipment Selection

- Types Of Essential Sealcoating Equipment

- Features to Prioritize in Sealcoating Machines

- Cost Considerations for Sealcoating Equipment

- Maintenance Tips for Sealcoating Equipment

- Environmental and Operational Best Practices

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

Understanding Sealcoating for Asphalt Maintenance

Sealcoating shields asphalt surfaces from wear, weather, and chemical damage. This protective layer fills surface cracks, blocks oxidation, and restores a jet-black finish. Proper application demands precise equipment matching the job’s needs and material specs.

Role Of Sealcoating in Protecting Asphalt Surfaces

Sealcoating acts as a barrier against water infiltration, UV degradation, and oil spills. Without it, asphalt binder breaks down, leading to raveling, cracks, and potholes. High-quality sealants with coal tar or asphalt emulsions require equipment that handles thick, abrasive mixtures. For example, spray systems with 200+ mesh filters prevent clogs from sand or polymer additives.

Impact Of Proper Equipment on Longevity and Quality

Using a worn-out sprayer or low-capacity mixer compromises sealant integrity. Inconsistent spray patterns leave thin spots, inviting moisture damage. Equipment like diaphragm pumps with 3,000 PSI output ensures even material flow, while steel-shaft paddles mix sealcoat to 450 RPM without separation. Projects lose 15-20% more material with undersized tanks requiring frequent refills.

Next, evaluating project size and equipment specs ensures cost-effective, lasting results. Let’s break down key factors for sealcoating equipment selection.

Key Factors in Sealcoating Equipment Selection

Picking the right tools for asphalt sealcoating hinges on balancing performance, durability, and job requirements. Let’s break down the critical elements that shape your decision.

Project Size and Scope

Job scale directly dictates equipment needs. A residential driveway demands different tools than a commercial parking lot.

Equipment Capacity for Small vs. Large Jobs

For under 5,000 sq ft, compact sprayers with 100-300-gallon tanks work best. Contractors handling 10,000+ sq ft daily need truck-mounted rigs or tow-behind systems pumping 8-10 gallons per minute. High-output machines cut labor time by 40% on large projects.

Durability and Material Quality

Sealcoat mixtures are abrasive. Equipment built with subpar parts wears out fast, costing more in repairs.

Choosing Corrosion-Resistant Components

Stainless steel pumps and poly tanks resist sealer chemicals better than standard steel. Look for spray wands with brass fittings—they last 3x longer than plastic in heavy use. Galvanized steel frames prevent rust in humid climates.

Sprayer Configurations and Applications

Your spraying method affects coverage speed and precision. Match the gear to your work style.

Spray Wands vs. Tow-Behind Systems

Handheld wands (like 24” fan patterns) excel for edges and tight spaces. Tow-behind sprayers cover 6-8 ft widths at 3 mph, ideal for open areas. Hybrid setups let crews switch between both—saving 15-20 minutes per job.

Pump Performance and Consistency

A reliable pump is the heart of any sealcoating machine. Weak pressure causes streaks; too much wastes material.

Ideal Pressure Settings for Smooth Application

Most sealers spray best at 150-200 PSI. Diaphragm pumps maintain steady flow without pulsation. Check adjustable pressure gauges—critical when switching between thin acrylics or thick coal-tar blends.

Essential Accessories for Efficiency

Don’t overlook add-ons that streamline tasks. The right extras prevent clogs and boost productivity.

Spray Hoses, Wands, and Mixing Tools

1/2” ID hoses reduce friction loss for longer sprays. Dual-stage mixers with 300+ RPM blades eliminate sealer clumps faster than hand stirring. Keep spare spray tips (0.065”–0.085” orifice sizes) to adjust material flow.

Armed with these insights, you’re ready to evaluate specific machinery types. Let’s examine the pros and cons of popular sealcoating setups.

Types Of Essential Sealcoating Equipment

Selecting the right tools determines efficiency and finish quality. Focus on three core categories: sprayers, crack fillers, and mixers.

Sealcoat Sprayers

Sprayers apply sealer evenly. Match the type to your project scale.

Handheld, Tow-Behind, and Truck-Mounted Options

- Handheld sprayers (5-15 gallons): Ideal for driveways or patches. Costs $200-$800. Use with coal-tar or asphalt-emulsion sealers.

- Tow-behind units (50-500 gallons): Fit parking lots up to 10,000 sq ft. Prices range $2,500-$12,000. Look for 12V pumps with 3-5 GPM flow rates.

- Truck-mounted rigs (500+ gallons): Built for commercial jobs. Requires 50+ HP engines and 8-10 GPM pumps. Expect $25,000+ investments.

Crack Filling Equipment

Precision matters. Melters, pour pots, and wand systems handle gaps from ¼” to 2” wide.

Compatibility with Asphalt Repair Products

Hot-applied rubberized sealants need 400°F-capable melters ($3,500-$7,000). Cold-pour sealers work with gravity-fed wands ($150-$400). Check viscosity ratings—equipment must manage 5,000-15,000 cP materials.

Mixing and Preparation Tools

Aggregates vary. Sand particles range 8-40 mesh. Use mechanical agitators to prevent settling.

Strategies for Handling Irregular-Size Materials

- Paddle mixers: Tackle clumps in 50-500-gallon tanks. ½ HP motors mix 1,000 lbs of slurry.

- Screens (1/4” mesh): Filter oversized debris pre-application.

- Heated storage tanks: Keep sealer at 50-70°F for consistent viscosity.

With core tools covered, let’s examine critical features that separate average machines from top performers.

Also See: Cold Mix Asphalt Equipment: Cost-effective Repairs

Features to Prioritize in Sealcoating Machines

Selecting the right tools requires balancing performance specs with job demands. Focus on three core elements: sprayer precision, material flexibility, and upkeep simplicity.

Sprayer Specifications

Sprayers form the backbone of any sealcoating setup. Prioritize models with clear pressure metrics—most systems operate between 1,500-3,000 PSI. Lower PSI works for thin sealers, while thicker blends need higher pressure to prevent clogs.

Tank Size, Nozzle Types, and Mobility

Tank sizes range from 50-gallon units for residential jobs to 500-gallon trailers for commercial projects. Contractors working on driveways might opt for compact tanks with 12” pneumatic wheels. Nozzle choice matters: fan tips create even coats on flat surfaces, while stream nozzles target cracks. Seek sprayers with stainless-steel wands—they last 2-3x longer than plastic variants.

Compatibility With Sealcoat Materials

Not all machines handle coal tar, asphalt emulsion, or polymer-modified sealers equally. Verify viscosity limits—most commercial-grade equipment manages materials up to 10,000 cP. Machines lacking thermal stability struggle with sealers requiring heating elements.

Adjustable Settings for Different Sealers

Look for sprayers with dial-controlled pressure regulators. These let you switch between products like sealer slurry (needing 20-30 psi) versus high-build coatings (requiring 40-60 psi). Dual-axis agitators prevent material separation in the tank, critical for mixes with sand or rubber additives.

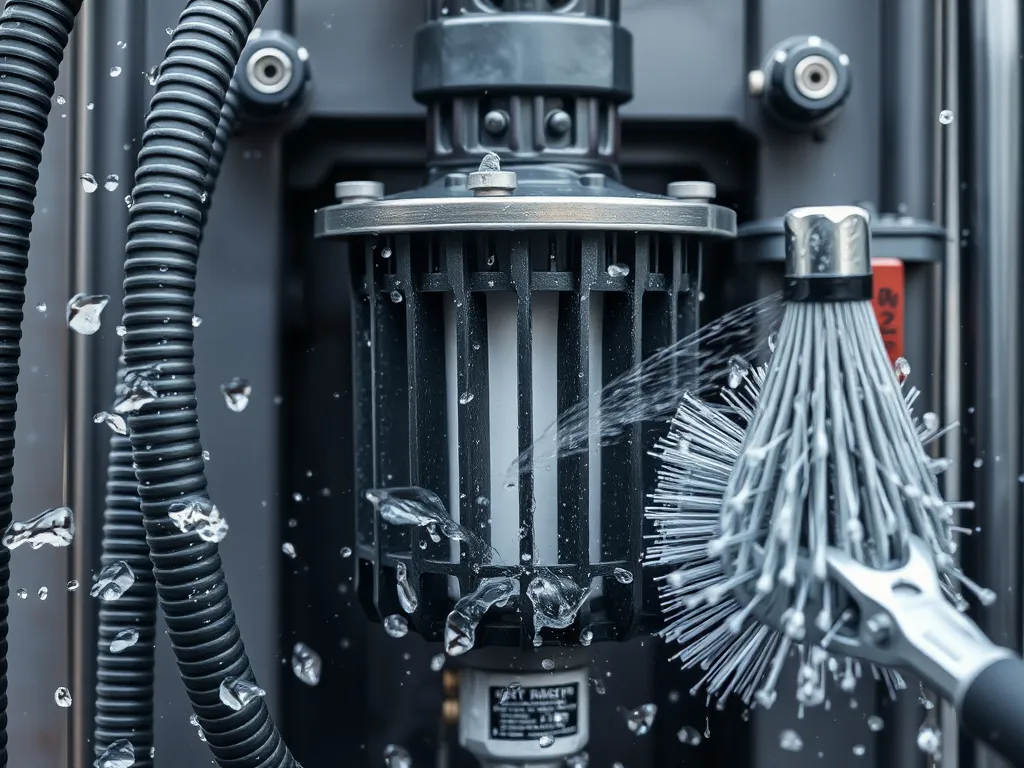

Ease Of Cleaning and Maintenance

Residue buildup ruins spray consistency. Opt for machines with quick-release hoses and screw-off filters. Budget 15-20 minutes post-job for rinsing: flush tanks with 5-10 gallons of water, scrub nozzles with wire brushes. Models with built-in flush kits cut cleanup time by half.

With these features in mind, the next step involves weighing upfront costs against long-term returns—key for maximizing profit margins.

Cost Considerations for Sealcoating Equipment

Smart financial planning separates profitable asphalt projects from costly missteps. Focus on three core areas to align your sealcoating equipment selection with both immediate needs and future growth.

Balancing Budget and Equipment Quality

Entry-level handheld sprayers start at $1,500, while commercial-grade truck-mounted systems exceed $20,000. Polyethylene tanks cut initial costs but crack under UV exposure faster than stainless steel. For contractors handling 10+ jobs monthly, a $12,000 rig with a 500-gallon tank and 5.5 HP pump prevents downtime. Small businesses tackling driveways may opt for a $3,000 tow-behind sprayer with a 200-gallon capacity.

Cost Per Gallon Analysis

Calculate operational efficiency by dividing equipment costs by gallons processed. A $5,000 machine sealing 500 gallons annually over 5 years delivers a $2/gal cost. Compare this to a $2,500 unit needing replacement after 200 gallons yearly for 2 years ($6.25/gal). High-volume contractors prioritize machines with 300+ gallon capacities and 60 PSI pumps to reduce labor hours per project.

| Equipment Type | Initial Cost | Gallons/Year | Lifespan | Cost/Gallon |

|---|---|---|---|---|

| Tow-Behind Sprayer | $3,200 | 1,200 | 4 years | $0.67 |

| Handheld System | $1,800 | 400 | 2 years | $2.25 |

Long-term Investment Vs. Short-term Needs

Contractors sealing 50,000+ sq ft annually require pressurized systems with 3/4″ hoses and dual-axis agitation. These $15,000+ setups handle coal tar and asphalt emulsions without clogging. Seasonal operators maintaining parking lots can use $4,000 electric diaphragm pumps with 1/2″ spray wands. Factor in sealcoating equipment maintenance costs: stainless steel spray tips last 300+ hours versus brass replacements every 75 hours.

Evaluating expenses upfront ensures your sealcoating machines match project demands without overspending. Next, learn how routine care extends equipment lifespan and protects your investment.

Maintenance Tips for Sealcoating Equipment

Proper care extends the lifespan of sealcoating machines and ensures consistent performance. Neglecting maintenance leads to clogged sprayers, pump failures, or rusted components – problems that derail projects and inflate costs. Let’s break down strategies to keep gear running smoothly.

Daily Cleaning Procedures

Flush spray systems immediately after each use. Residual sealer – coal tar or asphalt emulsion – hardens quickly, blocking nozzles and hoses. Use a pressure washer with 2,500 PSI to clear tanks, pumps, and hoses. For stubborn buildup, apply a solvent like diesel fuel or specialized cleaner. Prioritize equipment with quick-release fittings or stainless-steel parts to simplify this process. Machines designed for easy disassembly save 15–20 minutes per cleanup cycle.

Seasonal Storage Best Practices

Before storing equipment for winter, drain all fluids completely. Sealcoat materials left in tanks or pumps can solidify, causing permanent damage. Lubricate moving parts like sprayer triggers and pump pistons with non-petroleum grease. Store gear in dry, temperature-controlled spaces to prevent rubber seals from cracking. Polyurethane hoses and aluminum frames resist corrosion better than steel alternatives – a key factor during sealcoating equipment selection for contractors in humid climates.

Preventative Maintenance Schedules

Create a calendar-based plan for routine checks. Replace spray tips every 50 hours of use to maintain consistent coverage. Inspect diaphragms in pumps monthly; tears reduce pressure by 30–40%. For tow-behind systems, check tire pressure and axle alignment quarterly. Keep logs of part replacements – most sprayer motors last 800–1,200 hours before needing rebuilds. Proactive care avoids 70% of common sealcoating machine failures reported by asphalt professionals.

Well-maintained gear performs better and retains resale value. Next, let’s explore how operational practices impact both equipment longevity and environmental compliance.

Environmental and Operational Best Practices

Smart gear picks boost both earth care and job speed. Focus on tools that cut waste and handle green sealers right.

Minimizing Waste and Spillage

Pick sprayers with tight flow controls. Tow-behind rigs with 40-60 PSI settings stop drips. Match tank size to job needs—300-gallon tanks suit big lots; 100-gallon units fit driveways. Use spray wands with quick-shut valves to halt leaks fast. Add drip trays under pumps and hoses. Gear like sealcoat trailers with tilt guards cuts spill risk by 15% during transport.

Eco-friendly Sealcoat Material Handling

Choose gear that works with low-VOC sealers. Poly or stainless steel tanks resist rust from plant-based sealers. Sealed mixers stop fumes from escaping. Gear pumps (5:1 ratio) push thick, coal-tar-free blends smooth. For small crews, handheld sprayers with fine-tip nozzles spread water-based coats even. Clean gear with bio soaps to keep drains safe.

Proper tools and methods set the stage for success. Next, we’ll answer common questions about starting your sealcoating business.

Frequently Asked Questions

What Equipment is Needed to Start a Sealcoating Business?

To start a sealcoating business, you’ll need essential equipment such as sealcoat sprayers (handheld or tow-behind), crack filling tools, a mixing machine, protective gear, and transportation means like a trailer or truck. Investing in quality materials ensures efficient and professional results.

What Type Of Driveway Sealer Do Professionals Use?

Professionals typically use commercial-grade sealers which include coal tar emulsion or asphalt emulsion sealers. These options provide superior protection against UV rays, water damage, and wear, ensuring long-lasting asphalt surfaces.

How Many Gallons Of Sealcoat Are Needed Per Square Foot?

On average, you will need approximately 0.1 to 0.15 gallons of sealcoat per square foot for a standard application. However, this can vary based on the texture of the surface, the type of sealer used, and the application method. It’s crucial to estimate coverage accurately to avoid overspending on materials.

How Do I Know Which Sprayer Configuration is Right for My Project?

Your choice of sprayer configuration depends on the size and type of your project. For small driveways or tight spaces, handheld sprayers work well. For larger areas such as parking lots, tow-behind or truck-mounted sprayers are more efficient, allowing for faster coverage.

What is the Best Way to Maintain Sealcoating Equipment?

To maintain sealcoating equipment, follow regular cleaning procedures after each use, perform seasonal inspections, and stick to a preventative maintenance schedule. This includes checking filters, replacing worn parts, and ensuring that no sealer residue remains in hoses or tanks.

Are There Eco-friendly Options for Sealcoating Equipment?

Yes, there are eco-friendly sealers available that contain lower VOCs and are made from sustainable materials. Additionally, using efficient sprayers and minimizing waste can also contribute to environmentally responsible practices in sealcoating.

What Are the Common Mistakes to Avoid When Choosing Sealcoating Equipment?

Common mistakes include not considering the project size when selecting equipment, choosing low-quality materials that wear out quickly, and overlooking maintenance requirements. Always ensure compatibility between the sealer you plan to use and the equipment specifications to avoid inefficiencies.

Is It Necessary to Invest in Additional Accessories for Sealcoating Equipment?

Yes, additional accessories such as quality spray hoses, replacement wands, and mixing tools can significantly enhance efficiency and application quality. These items ensure a smoother operation, reduce the likelihood of clogs, and ultimately lead to better job results.

Closing Thoughts

Choosing the right sealcoating equipment is pivotal for achieving high-quality asphalt maintenance. Consider factors like project size, durability, and the specific needs of your job to ensure you select the best tools for the task. Prioritize equipment that offers flexibility, maintainability, and efficiency to enhance your project outcomes.

Cost matters too. Balance your budget with the quality of the equipment. Remember, investing in reliable sealcoating machines pays off in the long run through better performance and extended lifespan.

For more information and resources on asphalt sealcoating, visit Asphalt Calculator USA. Your journey towards optimal sealcoating starts here!

Additional Resources for You:

- Lavin, P. (2003). Asphalt Pavements: A Practical Guide to Design, Production, and Maintenance for Engineers and Architects. London: Taylor & Francis.

- sealcoating equipment | For Construction Pros

- Finding the Right Sealcoating Equipment | For Construction Pros

- Choosing Asphalt Sealcoating Equipment

- | AsphaltPro Magazine | How to Choose the Right Sealcoat Machine