How to Analyze Existing Asphalt Pavement Conditions: A Step-by-step Guide

Published on: January 17, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Analyzing existing asphalt pavement conditions involves evaluating surface quality, structural integrity, and material performance using visual checks, non-destructive tools, and lab tests. Engineers use methods ranging from basic crack mapping to advanced technologies like Ground Penetrating Radar (GPR) to measure layer thicknesses and detect hidden flaws. This process identifies repair needs, predicts pavement lifespan, and determines if recycling is viable.

This article explains core techniques for asphalt assessment. Learn how to document cracking patterns with ASTM D6433 standards. Discover how Falling Weight Deflectometers measure load-bearing capacity. Explore the Pavement Condition Index (PCI) rating system. We’ll cover infrared thermography for moisture detection, core sampling protocols, and cost-effective strategies to prioritize repairs. Data-driven examples show how combining methods improves decision-making for maintenance budgets from $15-$50 per square yard.

Contents

- Understanding Asphalt Pavement Condition Analysis

- Core Methods for Analyzing Asphalt Pavement Conditions

- Pavement Condition Index (PCI) for Asphalt

- Data Collection and Interpretation

- Environmental Factors in Pavement Checks

- FAQs About Asphalt Pavement Condition Analysis

- Closing Thoughts

- Useful References for You:

Understanding Asphalt Pavement Condition Analysis

Pavement condition analysis checks road health through set steps. It spots flaws, rates strength, and guides repair plans. This process uses visual checks, tech tools, and lab tests to find weak spots before they grow.

Purpose Of Asphalt Pavement Evaluation

Road checks aim to catch cracks, rutting, or drainage issues early. Teams track how well the asphalt holds weight and handles weather shifts. The Pavement Condition Index (PCI) – a 0-100 score – rates surface quality. PCI below 60 means urgent fixes. Tests also check layer thickness, base strength, and load limits per ASTM D6433 rules.

Consequences Of Neglecting Pavement Assessments

Skip road checks, and small cracks turn into potholes fast. Water seeps into base layers, causing sinkholes or washouts. Raveling (loose stones) cuts skid resistance, raising crash risks. Repair costs jump 30-50% if fixes are delayed past PCI 40. Roads may need full rebuilds at $150-$250 per ton instead of $50-$80 per ton for timely patches.

Ready to dig into the tools that spot these issues? Let’s break down the core methods used in pavement condition analysis.

Core Methods for Analyzing Asphalt Pavement Conditions

Four primary approaches form the foundation of pavement condition analysis: visual checks, non-destructive tests, destructive sampling, and analytical modeling. Each method provides unique data to determine road health and repair needs.

Visual Inspection Techniques

Trained evaluators conduct on-site surveys to detect visible defects. Standard tools include crack gauges, distress manuals, and digital cameras for documentation.

Spotting Surface Distresses in Asphalt

Common asphalt flaws to look for:

- Alligator cracking (interconnected cracks resembling reptile skin)

- Edge cracks within 2 feet of pavement boundaries

- Potholes exceeding 3-inch depth

- Rutting deeper than 0.5 inches

- Raveling with aggregate loss over 10% of surface area

Documenting Cracking Patterns and Severity

Measure crack widths using calibrated rulers:

- Low severity: <0.25 inches

- Moderate: 0.25-0.75 inches

- High: >0.75 inches

Map crack locations using GPS-enabled tablets paired with software like Esri ArcGIS.

Non-destructive Testing (NDT) Methods

Advanced technologies assess subsurface conditions without damaging the pavement. These methods collect 200-500 data points per mile for statistical accuracy.

Ground Penetrating Radar (GPR) for Asphalt Layers

GPR emits electromagnetic pulses (900-2500 MHz) to measure layer thickness. Detects:

- Asphalt depth variations ±0.1 inches

- Moisture infiltration zones

- Base layer erosion

Falling Weight Deflectometer (FWD) Testing

FWD applies 9,000-15,000 lbf loads to measure surface deflection. Outputs:

- Deflection basin parameters

- Layer modulus values (MPa)

- Load transfer efficiency at joints

Thermal Imaging Applications

Thermal cameras detect temperature variations (±1°F sensitivity) to locate:

- Poorly compacted areas

- Stripped binder zones

- Subsurface voids

Destructive Testing Approaches

Physical samples provide material properties for lab verification. Typically performed at 3-5 locations per mile.

Asphalt Core Sampling Procedures

6-inch diameter cores extracted using diamond-tipped drills (ASTM D5361). Stored in airtight containers at 40°F until testing.

Laboratory Analysis of Extracted Cores

Tests include:

- Bulk specific gravity (AASHTO T166)

- Binder content extraction (ASTM D2172)

- Gradation analysis of aggregates

Analytical Evaluation Methods

Combine field data with engineering models to predict pavement performance.

Structural Capacity Calculations

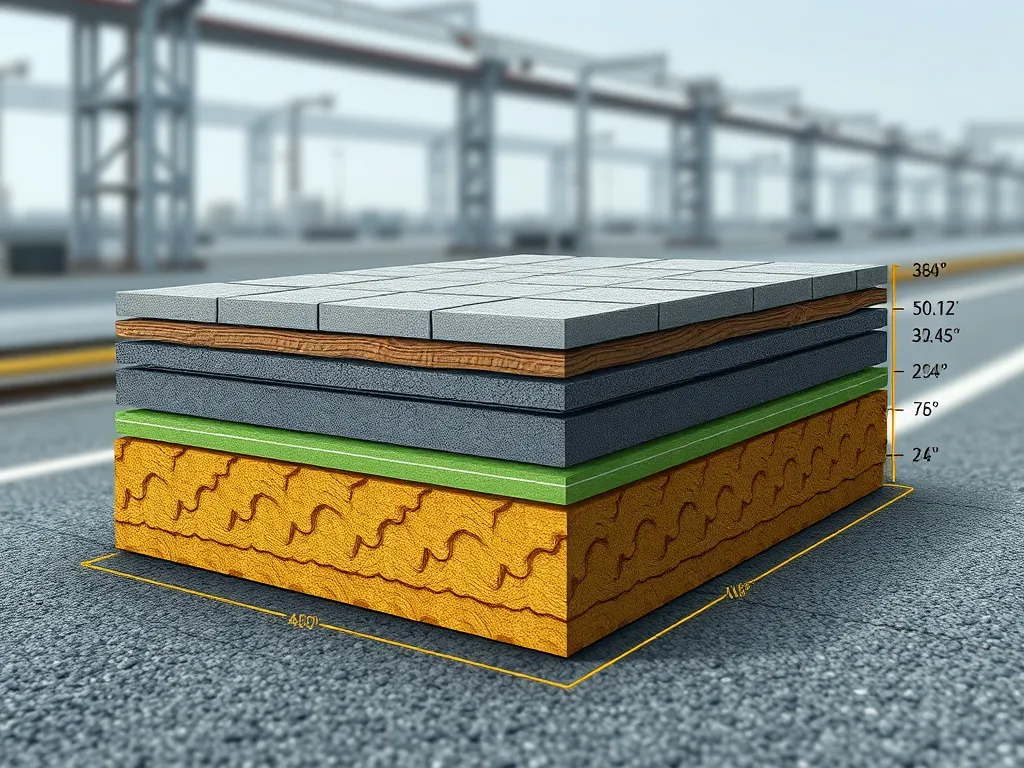

Use AASHTO 1993 equations to compute structural number (SN): SN = a1D1 + a2D2 + … + anDn Where a=layer coefficient, D=thickness (inches)

Load-Bearing Capacity Analysis

Calculate equivalent single-axle loads (ESALs) using: ESALs = (Axle Load / 18,000)4 Projects remaining service life based on traffic growth rates.

With pavement condition data collected, the next step involves converting findings into actionable scores using the Pavement Condition Index framework.

Pavement Condition Index (PCI) for Asphalt

The Pavement Condition Index (PCI) serves as the industry standard for quantifying asphalt surface quality. This 0-100 rating system translates field observations into actionable data, guiding maintenance decisions across roads, parking lots, and runways.

PCI Calculation Methodology

PCI analysis combines visual inspections with measured distress parameters. Teams catalog 19 common asphalt failures – from alligator cracking to raveling – recording each defect’s type, density, and severity.

Standardized Rating Scale (0-100)

Scores follow ASTM D6433 guidelines: 85-100 indicates minimal damage, 55-84 shows moderate deterioration, while sub-25 signals imminent failure. A Walmart parking lot scoring 72 would need targeted repairs, while a 48-rated highway lane requires structural rehabilitation.

Interpretation of PCI Ratings

PCI values dictate response strategies. Surfaces above 85 get preventive sealcoating. Scores between 70-84 trigger crack sealing and patching. Below 55? Full-depth reconstruction becomes cost-effective. Agencies typically allocate budgets when network averages drop below 65.

Factors Affecting PCI Scores

PCI accuracy depends on recognizing environmental and operational stressors. Northern states see 40% faster PCI decline than southern regions due to freeze-thaw damage. High-traffic corridors deteriorate twice as fast as local roads.

Climate Impacts on Asphalt Degradation

Temperature swings create thermal cracking – a 10°F daily fluctuation accelerates aging by 15%. Coastal salt spray corrodes binders 3x faster. In Phoenix, UV radiation degrades surface asphalt 0.12″ annually, requiring more frequent overlays.

Traffic Load Influences

Heavy vehicles dictate structural needs. A truck lane handling 10,000 ESALs (Equivalent Single Axle Loads) yearly needs double the base thickness of passenger car lanes. Unchecked overweight loads can slash PCI rates 30% faster than design projections.

With PCI data pinpointing vulnerabilities, the next phase integrates these findings with traffic records and weather patterns – key steps we’ll explore in data synthesis strategies.

Also See: Cold Mix Asphalt Application in Winter: Key Tips

Data Collection and Interpretation

Effective pavement condition analysis relies on merging field observations with quantitative measurements. This phase transforms raw data into actionable insights for maintenance decisions.

Essential Data Sources for Analysis

Start with historical records: construction dates, past repairs, and material specifications. Traffic data (AADT/ESALs) reveals load impacts – a single semi-truck axle causes 10,000x more damage than a passenger car. Climate records track freeze-thaw cycles and UV exposure degrading PG binder grades. Field measurements like International Roughness Index (IRI) scores and rut depth scans add precision. Lab tests on extracted cores measure asphalt content, aggregate gradation, and voids in mineral aggregate (VMA).

Modern tools enhance accuracy:

Combining Multiple Assessment Methods

Blend visual surveys with advanced tech for 360-degree insights. Pair crack maps from windshield surveys with GPR layer thickness data – 900 MHz antennas detect delamination within ±3mm accuracy. Cross-reference FWD deflection basin measurements (typically 0.2-1.0mm) with core sample stability tests. Infrared thermography spots subsurface voids missed by manual inspections.

A Michigan DOT study found combining methods reduces rehabilitation cost errors by 38%. Data fusion techniques like fuzzy logic algorithms weight inputs:

This multi-source approach identifies root causes: Alligator cracking + high deflections + thin surface course = base failure. Isolated potholes + good deflection readings = localized repair needed.

With layered data, agencies optimize budgets – mill-and-fill for PCI 70-85 pavements vs. full reconstruction under PCI 40. Up next: How environmental factors shape assessment strategies and recycling potential.

Environmental Factors in Pavement Checks

Green steps now shape how we check roads. Smart teams blend eco care with tech to cut harm and boost reuse.

Eco-check Methods

New ways cut the eco toll of road checks. Teams use life cycle checks (LCAs) to track impacts from build to fix. These scans log energy use, CO2, and waste at each step. Tools like PaLATE software crunch numbers for carbon math in real time.

| Eco-Check Tool | Use Case | Impact |

|---|---|---|

| LCAs | Track road life impacts | Cuts CO2 by 15-30% |

| Infrared cams | Spot heat loss in pavements | Reduces scan time by 40% |

| ASTM D8 tests | Check RAP quality | Allows 30-50% reuse rates |

Spotting Reuse Chances

Road checks now hunt for recyclables. Core drills pull samples to test RAP (crushed old asphalt) levels. GPR scans map layer depths to flag reuse zones. Labs check binder grade in old mix to set reuse rates.

| Reuse Sign | Test Method | Save Rate |

|---|---|---|

| High RAP quality | Core lab checks | Up to 95% reuse |

| Good base layers | GPR depth scans | 30% cost cut |

| Low crack spread | Drone crack maps | 50% less new mix |

These green finds set the stage for the next step: picking the right fix based on hard data.

FAQs About Asphalt Pavement Condition Analysis

What Are the Primary Methods Of Asphalt Pavement Evaluation?

The primary methods for evaluating asphalt pavement conditions include visual inspections, non-destructive testing techniques such as Ground Penetrating Radar (GPR) and Falling Weight Deflectometer (FWD) testing, destructive testing through core sampling, and analytical evaluation methods to estimate structural capacity and load-bearing capabilities.

How Does GPR Technology Work for Asphalt Assessment?

Ground Penetrating Radar (GPR) employs electromagnetic pulses to assess the thickness of asphalt layers and identify subsurface anomalies. It operates by transmitting signals that reflect off different layers within the pavement, allowing evaluators to visualize and quantify pavement conditions without causing damage.

What is the Analytical Method for Asphalt Pavement Design?

The analytical method for asphalt pavement design involves calculating the structural number (SN) and evaluating load-bearing capacity through established equations, such as those detailed in AASHTO guidelines. This approach integrates field data with engineering models to predict how pavement will perform under traffic loads.

How to Properly Assess Asphalt Pavement Conditions?

To properly assess asphalt pavement conditions, conduct a thorough visual inspection to identify surface distresses, use non-destructive testing methods for subsurface evaluation, perform core sampling for material analysis, and apply analytical models to interpret the data. Combining these approaches provides a comprehensive understanding of the pavement’s health and maintenance needs.

Closing Thoughts

Analyzing existing asphalt pavement conditions is vital for effective maintenance and longevity of roadways. By employing a combination of visual inspections, non-destructive and destructive testing, and analytical evaluations, you can accurately assess the health of your pavement. Awareness of key factors like climate and traffic loads will provide deeper insights into potential degradation, allowing for timely interventions.

Utilizing the Pavement Condition Index (PCI) offers a standardized approach to quantify conditions, making it easier to prioritize repairs and budgeting. Additionally, mixing various assessment methods enhances accuracy and assures sustainable practices, leading to more informed decisions regarding asphalt use and recycling options.

For more detailed information on asphalt pavement analysis, don’t forget to check out Asphalt Calculator USA.

Useful References for You:

- Practical Guide for Quality Management of Pavement …

- Intelligent pavement condition survey: Overview of current researches and practices – ScienceDirect

- SMART quality control analysis of pavement condition data for pavement management applications – ScienceDirect

- Pavement Condition Rating Systems – Pavement Interactive