How Thick Are Asphalt Driveways? Your Complete Guide

Published on: January 19, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Asphalt driveways typically require 2-3 inches of asphalt over 6-8 inches of compacted gravel base. Proper thickness ensures durability, prevents cracks, and supports vehicles up to 10,000 pounds. Exact measurements depend on vehicle types (cars vs RVs), soil stability (clay vs sandy soils), climate (freeze-thaw cycles), subbase quality, and budget constraints. Local building codes may mandate specific minimums.

This guide explains key factors like weight loads and soil tests, compares residential vs commercial standards, and details risks of thin asphalt layers. You’ll learn maintenance strategies to protect thickness, regional specs for areas like Biloxi or Gulfport, and how to use an asphalt thickness calculator. Data from Reddit discussions and industry charts helps you make informed decisions.

Contents

- Factors Influencing Asphalt Driveway Thickness

- Standard Thickness Guidelines for Asphalt Driveways

- Consequences Of Not Enough Thickness

- Choosing the Right Thickness for Your Driveway

- Maintaining Optimal Asphalt Thickness and Integrity

- Asphalt Driveway Thickness FAQ

- Final Thoughts

- Additional Resources for You:

Factors Influencing Asphalt Driveway Thickness

Your asphalt driveway’s lifespan depends on matching its thickness to five key variables. Let’s break down how each factor impacts structural requirements.

Vehicle Types and Weight Loads

Passenger cars (1.5-2 tons) need less support than RVs (6-12 tons) or delivery trucks (3-5 tons). For occasional car use, 2″ of asphalt over 4″ gravel base works. Heavy vehicles demand 3-4″ asphalt with 6-8″ aggregate base. A 3″ thick asphalt layer handles up to 8,000 lbs per axle without deformation.

Soil Composition and Stability

Clay soils expand when wet, requiring 50% thicker subbases than sandy soils. In Mississippi’s Coastal Plain (Biloxi/Gulfport areas), sandy loam allows 4″ subbases. Unstable soils may need geotextile stabilization fabric ($0.30-$0.75/sq ft) to prevent shifting.

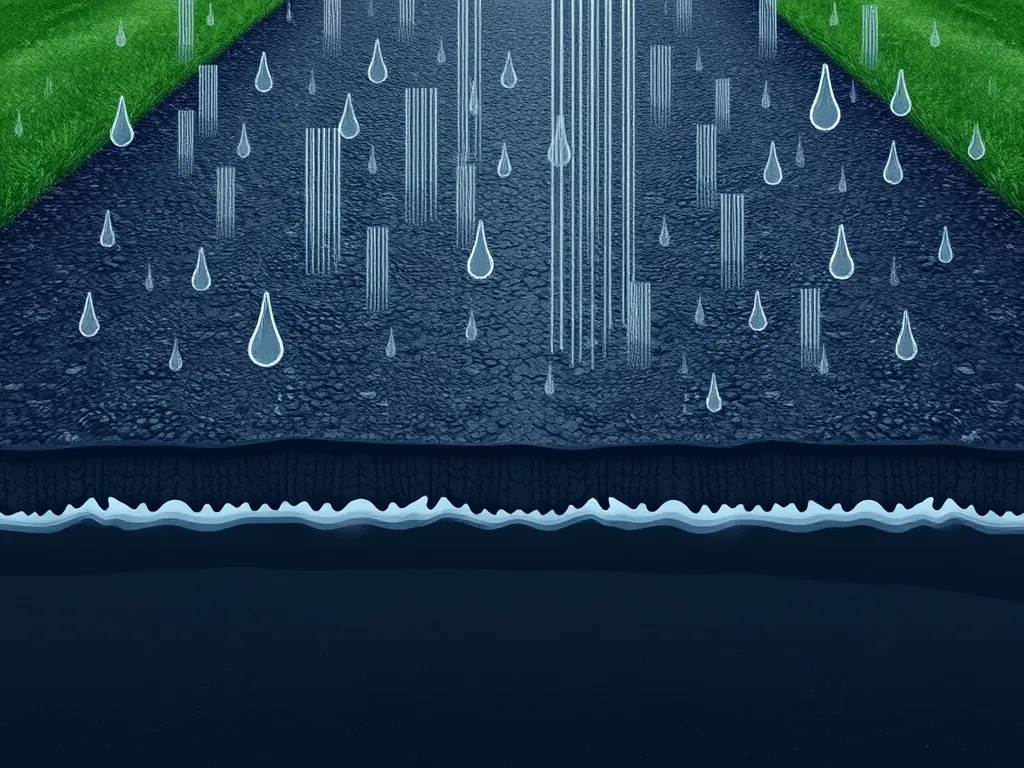

Climate and Weather Impact

Freeze-thaw zones (Midwest/Northeast) require 3-5″ asphalt to resist cracking. Southern heat demands PG 64-22 binder grades to prevent rutting. Coastal regions use 5% air voids in mixes for better drainage – 0.5″ thicker than standard drives.

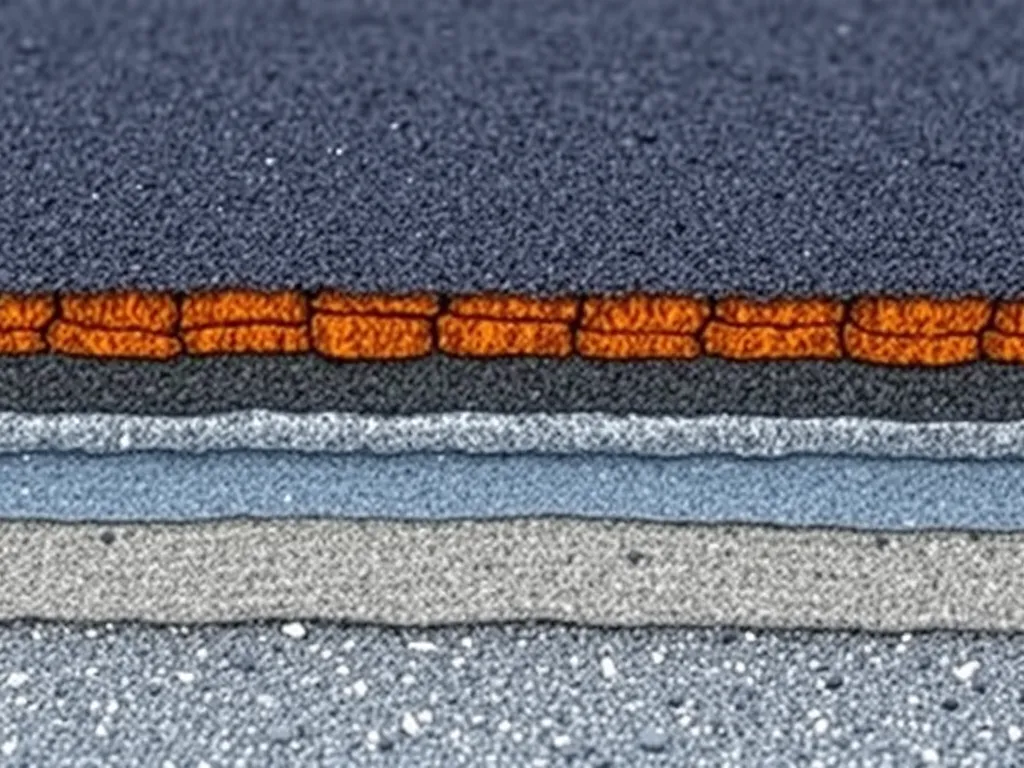

Subbase Preparation and Quality

A 95% compacted crushed stone base (6″ minimum) reduces asphalt thickness needs by 25%. Poor compaction leads to 40% faster deterioration. Gravel costs $1.50-$3.00/sq ft installed – cheaper than adding extra asphalt layers at $4.50-$6.50/sq ft.

Budget Considerations

Thicker drives (3″) cost 25-35% more than standard 2″ installations but last 50% longer. A 20’x20′ driveway costs $1,800-$2,500 at 2″ vs $2,400-$3,300 at 3″. Consider lifecycle costs – resealing 2″ drives every 2 years ($0.15-$0.25/sq ft) vs 3″ every 3-4 years.

Now that we’ve covered the key variables, let’s examine standard thickness specifications for different usage scenarios.

Standard Thickness Guidelines for Asphalt Driveways

Industry pros follow proven specs to build long-lasting pavements. Thickness impacts load capacity, crack resistance, and how long your surfacing lasts. Let’s break down common specs for various applications.

Residential Driveway Thickness (in Inches)

Most homes work with 2-3 inches of compacted asphalt. This sits on 6-8 inches of granular subbase (crushed stone or gravel). For cars and light trucks:

- 2 inches: Minimum for low-traffic areas (motorcycles, compact cars)

- 2.5 inches: Mid-range option for standard family vehicles

- 3 inches: Optimal for SUVs, RVs, or multi-car households

Cold climates or clay-rich soils might call for an extra 0.5-1 inch. A 3-inch layer with proper subbase can hold up to 8,000 lbs per axle.

Commercial/heavy-duty Driveway Thickness

Parking lots and industrial zones need stronger builds. Typical specs:

- 4 inches: Standard for store lots with cars only

- 6 inches: Truck docks or areas with semi-trailers

- 8 inches: Fuel terminals or military facilities

Subbases jump to 8-12 inches here. Contractors might add PG 76-22 binders (performance-graded asphalt) or Superpave mixes for high-traffic zones. Budgets run 30-50% higher than home projects.

Asphalt Thickness Chart Reference

This quick guide shows compacted asphalt specs:

- Residential surface: 2-3″ (19.5mm stone + PG 64-22 binder)

- Commercial surface: 3-4″ (25mm stone + PG 70-22 binder)

- Industrial base: 4-6″ (37.5mm stone + PG 76-22 binder)

Always confirm local codes. Biloxi, MS requires 3.5-inch mats for storm resistance, while Gulfport, MS allows 3-inch builds with 8-inch subbases.

With thickness specs locked in, what occurs if your pavement falls short? Up next: common issues from skimping on asphalt depth.

Consequences Of Not Enough Thickness

Skimping on asphalt thickness creates immediate and long-term risks. Thin layers lack the strength to handle daily wear, leading to visible defects and hidden weaknesses.

Cracking and Structural Damage

Driveways under 2.5 inches often develop alligator cracks within 2-3 years. These interconnected web-like patterns signal base layer failure. Heavy vehicles like trucks or RVs exert 50-100 PSI on surfaces. Thin asphalt can’t distribute these loads, causing ruts deeper than 0.5 inches or potholes requiring full-depth patches. Frost heave in colder regions worsens damage when thin layers allow moisture penetration.

| Thickness | Common Issues | Repair Frequency |

|---|---|---|

| 1.5-2″ | Alligator cracks, surface raveling | Every 1-2 years |

| 2-2.5″ | Edge cracks, minor rutting | Every 3-4 years |

| 3″+ | Localized surface cracks only | 5+ years |

Reduced Lifespan and Costly Repairs

Properly built 3-inch driveways last 15-20 years with maintenance. Thinner installations degrade faster, lasting 5-7 years before needing full replacement. Adding 1 extra inch during installation costs $1.50-$3 per square foot. Resurfacing a failing driveway runs $3-$7 per square foot. Full reconstruction reaches $8-$12 per square foot—triple the original cost.

Selecting the appropriate thickness requires analyzing usage patterns and local conditions. Next, let’s explore how to match your needs with proven thickness solutions.

Also See: How Asphalt Noise Barriers Improve Your Commute

Choosing the Right Thickness for Your Driveway

Assessing Vehicle Traffic and Usage

Driveway thickness ties directly to what rolls over it. Light cars like sedans need at least 2 inches of asphalt. Heavy trucks or RVs demand 3-4 inches. Daily use wears thin layers faster. For mixed traffic (cars + delivery vans), aim for 2.5-3 inches. Always match thickness to your heaviest vehicle’s axle weight.

Evaluating Soil and Drainage Conditions

Soft soil sinks. Hard soil holds. Test soil before paving. Clay-rich ground needs 6-8 inches of crushed stone base under asphalt. Sandy soil? 4-6 inches may work. Poor drainage? Add 0.5-1 inch to asphalt depth. Water pools crack thin layers. A 4-inch asphalt layer over 8 inches of gravel handles most wet soils.

Balancing Budget With Long-term Durability

Thinner driveways cost less now. A 2-inch layer runs $3-$5 per sq.ft. But it cracks in 5-7 years. A 3-inch layer costs 15% more but lasts 12-15 years. Recycled asphalt cuts costs by 20-25% but needs expert install. For best value, pair 3 inches of fresh asphalt with 6 inches of compacted base.

Now that you’ve sized up your needs, let’s explore how to keep that thickness intact through seasons and storms.

Maintaining Optimal Asphalt Thickness and Integrity

Keep your drive strong by protecting its depth. Let’s break down three key steps.

Preventing Damage From Heavy Loads

Park heavy rigs like RVs or dump trucks off the drive. Their weight (10,000+ lbs) can bend or crush the 2-3 inch top layer. Use plywood sheets under jacks or lifts to spread force. For daily use, limit loads to 8,000 lbs. Check tire PSI—over 50 psi strains the surface.

Timely Crack Repairs and Sealcoating

Fix cracks within 48 hours. Water in gaps softens the base, eroding 0.25-0.5 inches of asphalt yearly. Use hot-pour rubber filler for cracks wider than 0.25 inches. Sealcoat every 3 years with coal tar (lasts 5-7 years) or asphalt emulsion (3-4 years). This adds 0.125 inches of shield per coat.

Proper Snow Removal Techniques

Metal shovels scrape off 0.1-0.3 inches of asphalt per winter. Use plastic blades. Salt eats at the top layer—switch to sand or calcium chloride. Avoid deicers below 15°F; they freeze-thaw cycles split the surface. Plow blades should float 1 inch above the drive to prevent gouges.

Got these steps down? Next, let’s tackle your top questions on asphalt depth rules.

Asphalt Driveway Thickness FAQ

How Thick Should an Asphalt Driveway Be in Inches?

The thickness of an asphalt driveway should typically be between 2 and 3 inches for residential use. However, for heavy-duty applications or areas experiencing high traffic, a thickness of 3 to 4 inches may be necessary to ensure durability.

Is 1.5 Inches Of Asphalt Sufficient for a Driveway?

Generally, 1.5 inches of asphalt is considered insufficient for most residential driveways. This thickness may not provide adequate support for vehicles and can lead to cracking and other structural issues.

How Much Weight Can a 3-inch-thick Asphalt Driveway Hold?

A 3-inch-thick asphalt driveway can typically handle loads up to 8,000 pounds per axle without deforming. This makes it suitable for standard vehicles, including SUVs and light-duty trucks.

How Does the Asphalt Thickness Calculator Work?

An asphalt thickness calculator takes into account various factors such as vehicle weight, soil type, and climatic conditions to determine the appropriate thickness for your driveway. By inputting these parameters, you can receive a tailored recommendation that fits your specific situation.

What Do Reddit Users Say About Asphalt Driveway Thickness?

Discussion on Reddit often revolves around personal experiences with different asphalt thicknesses. Many users emphasize the importance of thickness in preventing cracks and damage, sharing insights on their long-term satisfaction with thicker driveways compared to thinner options.

How to Interpret an Asphalt Thickness Chart?

An asphalt thickness chart provides guidelines based on the intended use of the driveway, such as residential or commercial purposes. It typically lists the recommended thickness in inches alongside various load capacities, helping homeowners and contractors make informed decisions about installation.

Final Thoughts

Determining the proper thickness for your asphalt driveway is essential for ensuring durability, longevity, and cost-effectiveness. Understanding the factors that influence thickness—from vehicle weight loads to soil stability—enables homeowners and contractors to make informed decisions. Following standard guidelines helps in achieving a resilient surface that withstands traffic demands and environmental challenges.

Insufficient thickness can lead to cracking, structural damage, and expensive repairs. Regular maintenance, including timely crack repairs and sealcoating, plays a vital role in preserving asphalt integrity over time. Always aim for the recommended thickness based on your specific needs and conditions.

For further information and resources related to asphalt driveway thickness and more, check out Asphalt Calculator USA.

Additional Resources for You:

- The Asphalt Institute (Technical Resources & Standards)

- How many inches of asphalt are there for a driveway? – Quora

- General | OT: Driveway Asphalt thickness? | Practical Machinist – Largest Manufacturing Technology Forum on the Web

- Asphalt Thickness – Richfield Blacktop

- Asphalt Pavement Guide: Thickness – EastCoat Pavement Services