How is Asphalt Made? The Road Recipe Revealed

Published on: January 7, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Asphalt is made by mixing heated aggregates with asphalt cement at 300-350°F in industrial plants. Aggregates (crushed rock, sand, gravel) provide structure, while asphalt cement—a thick petroleum binder—acts as glue. Modern mixes often contain 20-30% recycled asphalt pavement (RAP), reducing landfill waste and cutting CO2 emissions by 15% versus new materials. Plants use drum mixers and computerized controls to ensure precise material ratios and temperatures for durable roads.

This article walks through the seven-step asphalt production process used in 4,000+ U.S. plants. We’ll break down how raw materials become pavement, explain additives like polymer-modified PG binders, and show how warm-mix asphalt tech slashes production temps by 50°F. You’ll also see quality checks that ensure mixes meet AASHTO M323 specs and learn how reclaimed shingles boost recycling rates.

Contents

- Introduction to Asphalt Production

- Key Components Of Asphalt

- The Asphalt Manufacturing Process

- Visualizing the Process: Asphalt Production Flow Chart

- Primary Applications Of Asphalt Mixtures

- Asphalt Vs. Cement: Key Strength Differences

- Environmental Considerations in Asphalt Production

- Frequently Asked Questions (FAQ)

- Closing Thoughts

- Additional Resources for You:

Introduction to Asphalt Production

Asphalt production transforms raw materials into paving material through precise engineering. The process combines aggregates (crushed stone, sand, gravel) with asphalt cement at high heat. Plants achieve this using batch or drum methods, producing 200-800 tons of mix per hour. Temperature control remains critical, with mixes heated between 275°F and 325°F for optimal binding.

Modern plants prioritize efficiency and eco-friendliness. Technologies like warm mix asphalt (WMA) lower production temperatures by 50°F, cutting fuel use by 20%. Recycled asphalt pavement (RAP) gets added to mixes, reducing virgin material needs by 15-30%. PG (Performance Grade) binders, tailored to regional climates, enhance pavement durability against cracking or rutting.

| Component | Role | Typical % in Mix |

|---|---|---|

| Aggregates | Structural backbone | 90-95% |

| Asphalt Cement | Binding agent | 5-10% |

| Additives | Enhance performance | 0.5-2% |

Plants follow strict guidelines like AASHTO M 323 and Superpave specifications. These standards ensure mixes meet traffic load and weather demands. Sensors track aggregate moisture levels, adjusting dryer temperatures in real time. Emission control systems capture 95% of particulates, aligning with EPA regulations.

Next, we’ll break down the exact materials that give asphalt its strength and flexibility.

Key Components Of Asphalt

Asphalt mixes use three core parts. Each plays a role in strength, flow, and life span.

Aggregates: The Primary Ingredient

Aggregates form 90-95% of asphalt by weight. These crushed rocks come from stone, sand, or gravel pits. Plants screen them into sizes from fine dust to 1.5-inch chunks. Gradation (size spread) affects density. Coarse rocks add load strength. Fines fill gaps for a tight bond.

Asphalt Cement: Derived From Crude Oil

Asphalt cement binds aggregates. Made by refining crude oil, it starts as bitumen. Refineries heat crude to split light fuels (gas, diesel) from heavy residues. Vacuum distillation pulls asphalt cement from these residues. This black glue makes up 5-10% of the mix. Plants heat it to 275-325°F for easy mixing.

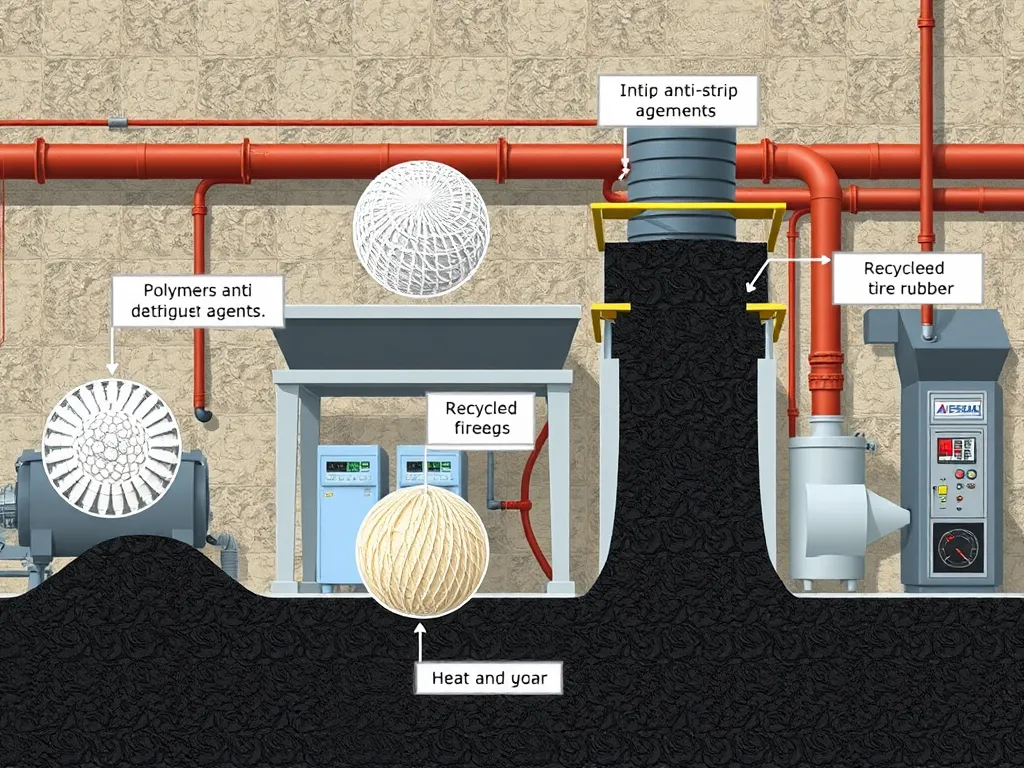

Additives and Modifiers

Special mixes need extra parts to beat heat, cold, or heavy traffic:

- Polymers (like SBS rubber): Boost bend strength by 40%

- Fibers: Stop cracks in thin layers

- Anti-strip agents: Keep water from breaking rock-glue bonds

- Recycled tire rubber: Cut road noise by 50%

Once these elements are prepped, plants blend them using strict heat and timing rules. Next, we break down the step-by-step asphalt making process.

The Asphalt Manufacturing Process

Modern asphalt production transforms raw materials into paving material through seven precise steps. Plants follow strict protocols to ensure durability, workability, and performance across road types.

Step 1: Aggregate Processing and Drying

Aggregates (crushed rock, sand, gravel) pass through screens and crushers to meet gradation specs. A rotary dryer then reduces moisture content to 0.5-3% at 300°F. Proper drying prevents steam bubbles during mixing and ensures binder adhesion. Common aggregates include granite, limestone, or recycled asphalt pavement (RAP).

Step 2: Precise Raw Material Weighing

Automated systems measure aggregates, asphalt cement, and additives. Load cells achieve accuracy within ±0.5%. A typical mix uses 90-95% aggregates and 5-10% asphalt cement. Optional modifiers like polymers or warm-mix agents get added here based on climate or traffic needs.

Step 3: Heating Aggregates to Optimal Temperatures

Dried aggregates move to a drum or batch heater. Temperatures reach 275-325°F depending on binder type. Heat activates the asphalt cement’s binding properties. Plants use natural gas, oil, or reclaimed energy sources to maintain efficiency.

Step 4: Combining Aggregates With Asphalt Cement

Hot aggregates meet liquid asphalt cement in a mixer. PG (Performance Graded) binders—classified by temperature resistance—get pumped at 280-350°F. High shear blades coat each stone thoroughly. Mix designs specify exact ratios: Interstate highways require stiffer binders like PG 76-22 compared to local roads.

Step 5: Thorough Mixing Of Components

The mixer runs 30-60 seconds to achieve uniform distribution. Temperatures stay above 250°F to prevent hardening. Sensors detect uneven coating, triggering adjustments. Properly mixed asphalt shows a glossy black finish with no visible dry spots.

Step 6: Storage and Loading for Transportation

Finished asphalt gets stored in silos at 250-300°F. Belly dump trucks load within 15 minutes to retain heat. Silos use agitation systems to prevent material separation. Projects requiring multiple mixes (base, intermediate, surface courses) schedule truckloads to match paving sequences.

Step 7: Rigorous Quality Control Measures

Labs test samples for gradation, binder content, and density. Nuclear gauges measure compaction, while ignition ovens verify asphalt percentages. Plants must meet ASTM D3515 and AASHTO M 323 specs. Failed batches get recycled or reprocessed before leaving the facility.

Want to see how these steps connect? The next section breaks down the entire asphalt production process through a detailed flow chart.

Also See: Asphalt in Urban Environments: Benefits and Drawbacks

Visualizing the Process: Asphalt Production Flow Chart

Asphalt mix production follows a tight flow from raw parts to final product. This flow chart maps each stage in the asphalt plant. Let’s break down the path from rock and oil to road-ready mix.

| Stage | Action | Key Points |

|---|---|---|

| 1 | Aggregate prep | Crushed stone, sand sorted into sizes |

| 2 | Drying & heating | 220-320°F to remove moisture |

| 3 | Mixing | Hot stone meets liquid asphalt binder |

| 4 | Quality checks | Test for grade, temp, texture |

| 5 | Storage | Held hot (280-325°F) until truck load |

Plants use two main types for making asphalt: batch plants and drum plants. Batch plants mix fixed amounts per cycle. Drum plants run non-stop, drying stone while mixing. Both follow the same core steps but vary in timing and gear.

Hot-mix asphalt (HMA) needs exact heat control. Aggregates heat to 300°F. Asphalt binder stays at 250°F. Mixing at these temps bonds stone to binder. Plants track temps using probes and infrared scans. Even a 15°F drop can ruin the batch.

Testing labs check samples during asphalt mix production. They run tests like gradation (stone size), binder content (5-7% by weight), and density. PG binders (like PG 64-22) are picked based on local weather. A PG 64-22 works in zones with temps from -22°F to 64°F.

Modern plants cut waste by reusing old asphalt. RAP (reclaimed asphalt pavement) can make up 30% of new mix. RAP cuts costs by $2-$5 per ton. Trucks haul fresh mix within 2 hours to keep heat and work time.

This flow shows why plant-made asphalt lasts 15-20 years on roads. Next, we’ll explore where these mixes go once they leave the plant.

Primary Applications Of Asphalt Mixtures

Asphalt mix types vary based on how they’re made. The blend of aggregates, binders, and additives shapes their best uses. Let’s explore where each mix works best.

Road Building

Most asphalt goes into roads. Plants make dense-graded mixes (like Superpave) for heavy traffic. These use 95% stone/sand and 5% asphalt cement. High heat during mixing ensures tight bonds for truck loads.

Driveways & Parking Lots

Open-graded mixes suit these surfaces. Made with larger stones and less sand, they drain water fast. Plants add polymer modifiers to handle freeze-thaw cycles. Mix temps stay at 300°F for proper flow during paving.

- Stone matrix asphalt (SMA) resists tire ruts in lots

- Porous asphalt reduces puddles with 16% void space

- Warm-mix types cut plant fuel use by 20%

Specialty Surfaces

How asphalt is made in the factory affects niche uses:

- Airport runways use PG 76-22 binders for heat resistance

- Racetracks get high-polymer mixes for grip

- Recycled asphalt (RAP) makes eco-friendly paths with 30% reused material

Mix designs directly link to how asphalt is produced. Next, see why these formulas outperform cement under stress.

Asphalt Vs. Cement: Key Strength Differences

Asphalt and Portland cement both build roads, but their structural capacity starts at production. Asphalt’s flexibility comes from bitumen – a sticky binder from crude oil. This allows pavings to flex under traffic loads without cracking. Cement gains rigidity through hydration, a chemical process mixing water with limestone-based powder.

Hot-mix asphalt (HMA) production at 300°F bonds aggregates tightly with bitumen, forming a viscoelastic surface. Roads can carry traffic within hours of cooling. Concrete needs 28 days to cure fully, forming rigid slabs. While strong in compression, this rigidity makes it prone to cracks from ground shifts or heavy truck loads.

Load Distribution & Maintenance

Asphalt’s dark color absorbs solar radiation, aiding self-healing of minor cracks in warm conditions. Its granular matrix spreads weight across multiple aggregate particles. Cement slabs transfer loads through their rigid structure, requiring expansion joints to handle temperature swings. Repair costs for concrete run 30-40% higher than asphalt overlays.

Material Innovation

Modern asphalt plants add polymers or rubber to boost high-temperature stability. PG (Performance Graded) binders tailor mixes for specific climates. Concrete uses steel rebar for tensile strength but can’t match asphalt’s 95% recycling rate. Warm-mix asphalt tech now cuts plant temps to 250°F, slashing fuel use by 20%.

Both materials play vital roles in infrastructure. Up next: how asphalt plants cut their impact on surroundings while supplying 420 million tons of mix annually.

Environmental Considerations in Asphalt Production

Modern asphalt plants prioritize sustainability through advanced recycling and emission controls. The asphalt production process now reuses 95% of old pavement material, cutting virgin aggregate needs by 30% in typical mixes. This shift reduces landfill waste and slashes material costs by $2–$5 per ton.

Key eco-friendly practices include:

- Recycled Asphalt Pavement (RAP): Crushed existing asphalt gets blended into new mixes at 140–175°F, saving 350 million tons of virgin aggregate annually

- Warm-Mix Asphalt (WMA): Lowers production temps from 300–330°F to 230–280°F using chemical additives or foaming. Cuts CO₂ emissions by 15–30% per ton

- Baghouses: Industrial filters capture 99.9% of particulate matter during drying and mixing

Plants like the Gencor UltraSpan® now integrate carbon capture systems, trapping 8–12 tons of CO₂ daily. Solar-powered drum dryers and reclaimed heat systems reduce energy use by 18–22% compared to traditional methods.

Porous asphalt mixes – with 18% minimum void space – manage stormwater runoff during road use. These surfaces filter 80–90% of rainfall, reducing urban flooding risks while recharging groundwater.

Let’s explore common questions about how asphalt is made in a plant and its real-world applications.

Frequently Asked Questions (FAQ)

What is the Main Ingredient in Asphalt?

The primary ingredient in asphalt is aggregates such as crushed stone, sand, and gravel, which make up 90-95% of the mix by weight. Asphalt cement, derived from crude oil, serves as the binding agent, constituting about 5-10% of the mix.

Is Asphalt Made Using Tar?

No, modern asphalt is not made using tar. Asphalt is primarily composed of asphalt cement, which is produced from the distillation of crude oil. Tar is a different substance, traditionally produced from coal, and is not commonly used in asphalt production today.

How Does the Asphalt Production Flow Chart Work?

The asphalt production flow chart visually represents the steps involved in producing asphalt, starting from aggregate preparation and drying, through mixing with asphalt cement, to quality checks and storage before transportation. It helps in understanding the sequential process that ensures a consistently high-quality final product.

How is Freshly Made Asphalt Installed on Roads?

Freshly made asphalt is typically installed on roads using specialized paving machines that lay the hot mix in a uniform layer. The asphalt is compacted while it is still warm to ensure that it adheres properly and forms a stable surface. After laying, it takes a few hours to cool down before it can handle traffic.

Closing Thoughts

Asphalt production is a precise blend of materials and processes, resulting in the durable surfaces we rely on daily. From aggregates to asphalt cement, each component plays a pivotal role in the final product. Understanding how asphalt is made empowers both industry professionals and the general public to appreciate its significance in construction and infrastructure.

Whether you’re looking to construct a new driveway, pave a road, or simply learn more, the insights shared here illustrate the complexity behind this essential material. Remember to consider its impact on the environment and the efficiency gains that come from innovative manufacturing practices.

For further information and resources on asphalt production and its applications, check out Asphalt Calculator USA.