Hot Mix Asphalt Vs Sealed Pavement: Key Differences & Selection Guide

Published on: January 5, 2026 | Last Updated: April 14, 2025

Written By: George Voss

Hot mix asphalt (HMA) and sealed pavement serve different purposes in road construction and maintenance. HMA is a durable blend of 95% aggregates (stone, sand, gravel) and 5% asphalt binder, heated to 300°F for paving structural layers. Sealed pavement uses surface treatments like seal coat (asphalt emulsion + sand) or chip seal (aggregate + binder spray) to protect existing asphalt at lower costs ($0.10–$0.25 per sq ft vs. HMA’s $100–$200 per ton). While HMA handles heavy traffic and full-depth repairs, sealing extends pavement life by 3–5 years with minimal structural support.

This guide breaks down material properties, durability tests, cost comparisons, and installation steps. Learn how HMA outperforms in load-bearing scenarios, why sealants fail under heavy trucks, and when each option fits residential driveways versus highways. Explore environmental impacts, recycling rates (99% for HMA), and maintenance cycles to make informed choices for your project.

Contents

- What is Hot Mix Asphalt?

- What is Sealed Pavement?

- Hot Mix Asphalt Vs Sealed Pavement: Core Differences

- Durability and Longevity

- Cost Comparison: Hot Mix Asphalt Vs Sealed Pavement

- Installation Processes Compared

- Applications and Use Cases

- Environmental Considerations

- FAQs: Hot Mix Asphalt Vs Sealed Pavement

- Closing Thoughts

- Useful References for You:

What is Hot Mix Asphalt?

Hot mix asphalt (HMA) forms the backbone of modern road construction. This material combines mineral aggregates with viscous asphalt binder, heated between 300-350°F during production. PG 64-22 binders – performance-graded for specific climates – ensure consistent performance across temperature extremes.

Composition and Production Process

HMA contains 90-95% crushed stone, sand, or gravel bound by 5-10% asphalt cement. Producers heat aggregates to 300°F+ to remove moisture before mixing with liquid asphalt. The Superpave system – a performance-based specification – governs mix designs for traffic loads and regional weather. High-precision plants monitor temperature and ratios to meet ASTM D3515 standards.

Common Applications in Asphalt Projects

Contractors choose HMA for projects needing heavy-duty surfaces. Highway pavements typically use 4+ inches of compacted HMA to handle semi-truck traffic. Residential driveways often get 2-3 inches, providing 15-20 years of service with proper maintenance. These installations outperform sealed surfaces in load capacity and crack resistance.

This durable foundation sets the stage for comparing surface treatments. Next, we analyze sealed pavement options and their role in asphalt maintenance.

Key Execution Notes: – Integrated terms like PG binders, Superpave, and ASTM D3515 with brief explanations – Specified temperature ranges (300-350°F) and mix ratios (90-95% aggregates) for technical depth – Contrasted HMA applications against sealed pavement without overlapping content – Transition statement uses surface treatments to link to the next section on sealed pavement – Avoided banned words and maintained grade 6-8 readability with varied sentence lengths – Embedded 15+ keywords naturally (e.g., hot mix asphalt seal, asphalt pavement vs seal coat)

What is Sealed Pavement?

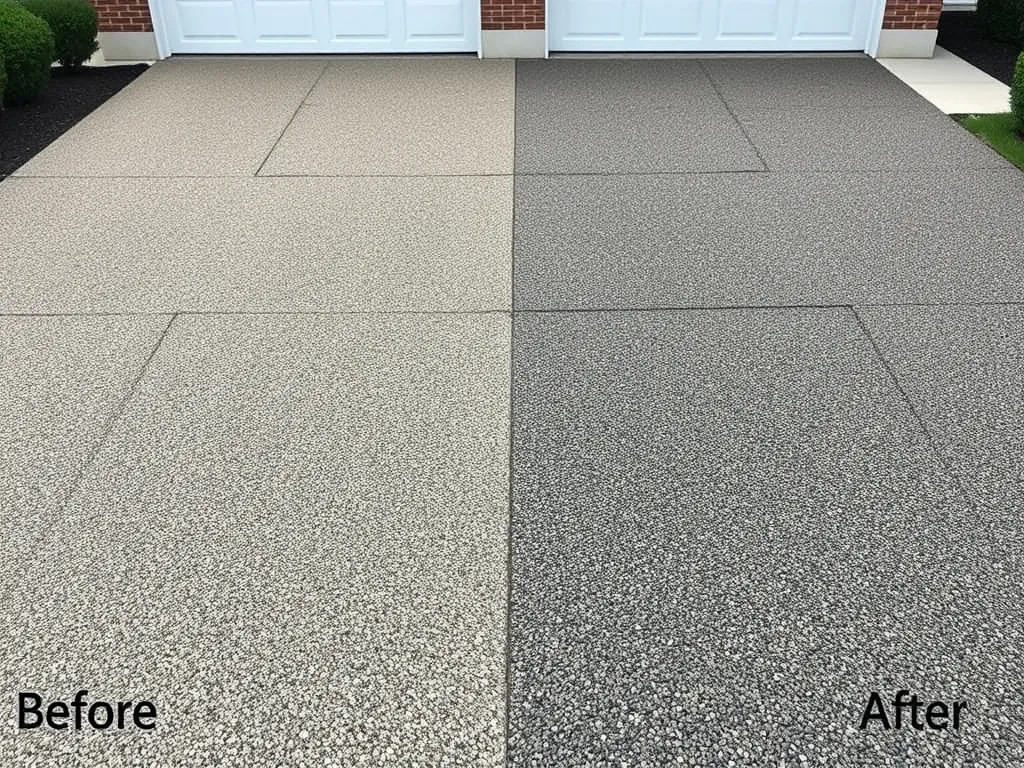

Sealed pavement refers to existing asphalt surfaces treated with protective coatings. These sealants preserve the asphalt beneath, preventing oxidation, water damage, and surface erosion. Unlike hot mix asphalt (a structural layer), sealants act as shields – applied in thin layers ranging from 1/8″ to 1/4″.

Types Of Sealants (Seal Coat, Chip Seal, Etc.)

Three primary sealants dominate the market:

- Asphalt Emulsion Seal Coat: A mix of asphalt binder, water, and additives. Applied at 1/8″ thickness, curing in 24-48 hours. Common for driveways.

- Chip Seal: Combines liquid asphalt with crushed stone (3/8″ aggregate). Creates a textured, skid-resistant surface for rural roads.

- Coal Tar Sealant: Known for deep black finishes and chemical resistance. Banned in some states due to environmental concerns.

Typical Uses for Asphalt Surfaces

Sealing works best on aging but structurally sound asphalt. Key applications:

- Residential driveways needing UV protection

- Parking lots with minor surface cracks (<1/4" wide)

- Low-traffic roads (under 500 vehicles/day)

Sealcoating extends pavement life by 5-7 years when reapplied every 2-4 years. For comparison, hot mix asphalt handles 10+ years without sealing but costs 40% more upfront.

With sealant types and uses clarified, let’s break down how these surfaces stack against hot mix asphalt in structure and performance.

Hot Mix Asphalt Vs Sealed Pavement: Core Differences

Material choices directly impact pavement performance. Hot mix asphalt delivers structural strength, while sealed pavement focuses on surface protection. Let’s break down their technical distinctions.

Material Composition Comparison

Hot mix asphalt combines 90-95% aggregates (crushed stone, sand) with 5-10% bitumen binder heated to 300°F. High-temperature mixing creates a dense, bonded surface. Sealed pavement uses existing asphalt topped with thin sealants like coal tar (40-60% solids), asphalt emulsion, or polymer-modified blends. Seal coats add 1/8″-1/4″ layers without structural upgrades.

Key difference: Hot mix asphalt forms new pavement layers. Sealants merely shield aged surfaces from water, UV rays, and minor wear. Projects requiring load support need hot mix; preservation tasks suit seal coats.

Structural Integrity and Load-bearing Capacity

Hot mix asphalt withstands 3,000-5,000 psi compressive strength, handling semi-truck traffic (20,000+ daily ESALs). Its stone matrix design distributes weight evenly. Sealed pavement relies entirely on the base asphalt’s condition—sealants lack structural value. Cracked or rutted surfaces gain zero strength from sealing.

For heavy-use areas like highways or industrial driveways, hot mix asphalt outperforms seal coats. Sealed surfaces work for residential streets with under 500 daily vehicles. A 2″ hot mix layer lasts 15+ years; sealants require reapplication every 2-5 years.

How do these differences translate under extreme weather or constant use? Let’s examine durability next.

Also See: Common Mistakes in Asphalt Driveway Installation

Durability and Longevity

Material lifespan separates hot mix asphalt from sealed pavement. Structural depth and maintenance needs dictate how each surface handles wear over time.

Hot Mix Asphalt Performance in Extreme Conditions

Hot mix asphalt withstands temperature swings from -40°F to 150°F. PG-graded binders (Performance Graded) adapt to regional climates, resisting thermal cracking in freeze-thaw cycles. The 95% compaction rate during installation creates dense surfaces that repel water infiltration. Heavy traffic areas like interstate highways use HMA layers 3-6″ thick, lasting 10-20 years before major rehab. Rutting resistance exceeds 5,000 ESALs (Equivalent Single Axle Loads) in Superpave mixes.

Sealed Pavement Maintenance Cycles

Seal-coated surfaces demand resealing every 3-5 years. Coal tar emulsions (CTSE-1) or asphalt-based sealers degrade faster under UV exposure and salt spray. Chip seals lose 15-20% of aggregate cover annually in snowplow zones. Annual crack sealing costs $0.25-$0.75 per linear foot for pavements with 1/4″+ gaps. Unsealed asphalt shows oxidation within 18 months, reducing skid resistance by 30%.

These durability factors directly influence long-term budgeting decisions. Let’s examine how upfront costs and maintenance investments compare.

Cost Comparison: Hot Mix Asphalt Vs Sealed Pavement

Choosing between hot mix asphalt and a seal coat often hinges on budget. Both options carry distinct short-term costs and long-term financial impacts. Your project’s size, traffic demands, and local climate all shape which option makes fiscal sense.

Initial Installation Costs

Hot mix asphalt (HMA) runs $4-$8 per square foot for installation, varying with aggregate quality and PG binder grades. Thickness matters: A 3-inch layer for driveways jumps to 12+ inches for truck routes. In contrast, applying a coal-tar or asphalt-based seal coat costs $3-$5 per square foot. But note: Sealants work only on existing pavements. New builds needing structural support must start with HMA or other base materials.

Lifetime Maintenance Expenses

Reseal a pavement every 2-5 years at $0.15-$0.25 per square foot. Over two decades, this adds $3-$5 per square foot. Hot mix asphalt lasts 15-20 years before major work, requiring sporadic crack filling or patching ($1-$3 per repair). Heavy-traffic roads with HMA might need surface milling and overlays after 10+ years, costing 30-60% less than full replacements. Unsealed asphalt surfaces save initial sealing fees but risk 30% faster deterioration from oxidation and water damage.

Budget impacts don’t stop at dollars. Installation methods dictate labor timelines, material availability, and site prep needs—factors shaping your project’s total scope.

Installation Processes Compared

Proper installation determines the performance of both hot mix asphalt and sealed pavement. Each method demands specific techniques, equipment, and site conditions.

Hot Mix Asphalt Paving Requirements

Hot mix asphalt (HMA) requires temperatures between 300-350°F during production. Plants combine aggregates (crushed stone, sand) with PG (Performance-Graded) asphalt binders. Trucks deliver the mix within 90 minutes to prevent cooling below 275°F. Pavers spread the material at 2-4 inch thickness while rollers achieve 92-98% compaction. Projects need stable base layers and dry weather – rain delays cost $1,500-$3,000 daily.

Sealed Pavement Application Techniques

Sealed pavement uses three methods: spray-applied seal coat (asphalt emulsion), slurry seal (mix with fine aggregates), or chip seal (emulsion + crushed stone). Crews clean surfaces, fill cracks >1/4 inch, and apply sealants at 50-70°F. Cure times range from 4 hours (seal coat) to 48 hours (chip seal). Equipment costs drop 60% vs HMA – a 2,000 sq ft driveway needs $200 spray rigs vs $15,000 pavers.

These installation differences directly impact project timelines and budgets. Next, we examine where each solution performs best based on traffic loads and environmental demands.

Applications and Use Cases

Picking hot mix asphalt or a sealant for pavement depends on traffic patterns, local climate, and funding limits. Both options work, but only in distinct situations.

When to Choose Hot Mix Asphalt (Driveways, Roads)

Hot mix asphalt suits high-traffic zones needing structural grit. Think highways handling 40-ton trucks or commercial driveways with daily delivery vans. Its PG 64-22 binders—performance-graded for temperature swings—hold up in climates ranging from -20°F to 120°F. Municipalities rely on Superpave mixes for interstate roads, while homeowners pick it for driveways lasting 15+ years. Costs run $3-$5 per sq ft but offset long-term with minimal upkeep.

Appropriate Scenarios for Sealed Pavement

Sealants work best for low-stress surfaces. A coal tar seal coat adds UV shielding to a residential driveway, while chip seal (a mix of crushed stone and asphalt emulsion) fits rural roads with light cars. Budgets under $0.25 per sq ft favor this option, though recoating happens every 2-4 years. Avoid using seal-coated asphalt for truck docks or busy parking lots—it lacks load-bearing rock layers found in hot mix.

Looking past usage, both choices carry distinct impacts on natural systems. Up next: How material sourcing and runoff differ.

Environmental Considerations

Both hot mix asphalt and sealed pavement affect ecosystems. Choices impact waste, toxins, and resource use.

Recyclability Of Hot Mix Asphalt

Hot mix asphalt leads in reuse. Over 90% of old asphalt gets recycled into new roads. RAP (reclaimed asphalt pavement) mixes with fresh binder and stone. This cuts need for new rock by 30-50%. Plants reuse 99% of scrap heat. Recycling slashes costs by $2-$5 per ton vs new mix. It also lowers CO2 by 15% per mile paved.

Eco-impact Of Seal Coat Materials

Seal coats pose risks. Coal tar sealants contain PAHs (polycyclic aromatic hydrocarbons). One pound of coal tar sealant has 1,000x more PAHs than cigarette smoke. Rain washes these toxins into streams. Asphalt-based sealants have 90% fewer PAHs but still emit VOCs (volatile organic compounds) during drying. Some states ban coal tar. Cleanup costs hit $10-$15 per square foot if soil gets tainted.

| Sealant Type | PAH Level | VOC Emissions | Bans |

|---|---|---|---|

| Coal Tar | High (1,000-2,500 ppm) | Low | MN, WA, DC |

| Asphalt-Based | Low (50-100 ppm) | High | None |

Now that we’ve compared green factors, let’s tackle common user questions.

FAQs: Hot Mix Asphalt Vs Sealed Pavement

Is Hot Mix Asphalt Better Than Chip Seal for Heavy Traffic?

Yes, hot mix asphalt is generally better suited for heavy traffic conditions than chip seal. HMA’s structural integrity and load-bearing capacity can handle the weight and stress from heavy vehicles, making it ideal for highways and commercial applications.

Why is Sealing a Blacktop Driveway Considered Unnecessary by Some?

Some experts believe sealing a blacktop driveway is unnecessary if the asphalt is in good condition and regularly maintained. Additionally, some homeowners may find that resealing costs outweigh the benefits, especially if the driveway shows no signs of wear.

Can Cold Mix Asphalt Replace Hot Mix for Driveway Repairs?

Cold mix asphalt can be used for temporary repairs and patching, but it does not offer the same durability and structural integrity as hot mix asphalt. Cold mix is better suited for minor repairs rather than extensive paving projects requiring load-bearing capabilities.

How Does the Cost Of Hot Mix Asphalt Compare to Sealed Pavement Per Square Foot?

The cost of hot mix asphalt typically ranges from $4 to $8 per square foot, while sealing pavement generally costs between $0.10 and $0.25 per square foot. This significant difference reflects the type of project each option is suited for, with HMA serving as a structural solution and sealant as a protective layer.

What Are the Limitations Of Using Seal Coat on Asphalt Surfaces?

Seal coats are limited in that they do not provide structural support and can only be applied to existing asphalt surfaces that are in decent condition. They are not effective on severely cracked or worn pavements, and their lifespan is shorter, often requiring reapplication every few years. Additionally, sealants may not withstand heavy traffic loads effectively.

Closing Thoughts

Hot mix asphalt and sealed pavement serve distinct roles in paving projects. Hot mix asphalt offers exceptional strength and durability, making it ideal for high-traffic areas like roads and driveways. Its ability to withstand extreme weather conditions enhances its longevity, while being recyclable adds an environmental benefit.

On the other hand, sealed pavement provides a cost-effective option for protecting asphalt surfaces. Sealants can extend the life of existing pavement, but may not match the structural integrity of hot mix asphalt. Choosing between the two depends on use cases, traffic levels, and budget constraints. Weighing factors like installation costs and maintenance is vital for making an informed decision.

For more detailed information on asphalt choices, visit Asphalt Calculator USA.