Keep Your Asphalt Strong: Expert Maintenance Guidelines That Last

Published on: December 25, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Regular asphalt maintenance involves scheduled care practices like crack sealing, sealcoating, and drainage management to protect surfaces from weather, traffic, and aging. Unlike reactive repairs, these proactive steps prevent potholes, extend pavement life by 15-25 years, and cut long-term costs by up to 50%. Proper care keeps surfaces safe, avoids tripping hazards, and maintains curb appeal. Key tasks include applying coal tar or asphalt emulsion sealants every 2-3 years, fixing cracks within 48 hours of spotting them, and using thermoplastic markings for visibility.

This guide breaks down asphalt care into actionable steps. Learn how often to clean driveways versus parking lots. Compare crack filling (for small gaps) versus crack sealing (for larger fractures). Get timing tips: sealcoat in 60-85°F weather, repair potholes before winter freeze-thaw cycles. We’ll cover cost-saving methods like infrared patching ($2-$5 per sq ft) and eco-friendly options like recycled asphalt pavement (RAP). Explore checklists for weekly inspections and annual resurfacing decisions.

Contents

- Importance Of Regular Asphalt Maintenance

- Understanding Routine Asphalt Pavement Maintenance

- Essential Asphalt Driveway Maintenance Procedures

- Developing an Effective Asphalt Maintenance Checklist

- How Often Should You Perform Asphalt Maintenance?

- Maintenance Tasks for Asphalt Overlay Systems

- Environmental Considerations in Asphalt Care

- Key Factors Impacting Asphalt Longevity

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

Importance Of Regular Asphalt Maintenance

Preserving your paved surfaces requires consistent care. Proper upkeep prevents minor issues from becoming costly reconstruction projects. Without scheduled interventions, even high-quality installations degrade faster due to oxidation, traffic stress, or freeze-thaw cycles.

Proactive care extends pavement life by 10-15 years. Studies show spending $1 on preventive measures saves $3-$5 in future rehabilitation. Timely crack sealing blocks water intrusion into sublayers—the primary cause of potholes, rutting, or base failures. Sealcoating every 3-5 years protects against UV damage, fuel spills, and raveling.

| Neglected Issue | Potential Repair Cost |

|---|---|

| Unsealed cracks | $2.50-$4.00 per linear foot |

| Potholes | $50-$300 per hole |

| Full-depth base repair | $8-$15 per square foot |

Beyond financial savings, maintained surfaces improve traction for vehicles. Properly graded pavement directs stormwater runoff efficiently, lessening hydroplaning risks. Municipalities frequently require compliance with asphalt pavement maintenance guidelines to meet safety codes or environmental permits.

Including recycling in your asphalt maintenance program supports sustainability goals. Reclaimed asphalt pavement (RAP) constitutes over 99% recyclability, lowering material costs by 20-30%. Newer methods like cold-in-place recycling further reduce emissions during repairs.

Putting these asphalt maintenance recommendations into practice demands systematic planning. Let’s explore specific methods to keep surfaces functional for decades.

Understanding Routine Asphalt Pavement Maintenance

Effective asphalt maintenance guidelines combine proactive care with targeted repairs. Regular upkeep prevents minor issues from escalating into costly structural damage.

Cleaning and Debris Removal for Asphalt Surfaces

Weekly sweeping removes abrasive particles that degrade surfaces. Use power washers at 2,500-3,000 PSI for oil stains or accumulated grime. Prioritize clearing:

- Leaves and organic matter causing moisture retention

- Gravel or road salt accelerating wear

- Fuel spills breaking down binder compounds

Neglected debris creates ideal conditions for raveling and oxidation. Municipalities often deploy regenerative-air sweepers for large parking lots.

Crack Sealing and Filling Procedures

Address cracks under 0.5″ wide with rubberized asphalt emulsion. For larger fissures (>0.75″), use hot-pour polymer-modified sealant applied at 350-400°F. Key steps:

- Clean cracks with compressed air or rotary wire brushes

- Apply bond breaker tape for non-working joints

- Pour sealant 1/8″ above surface to allow for settling

Proper crack treatment prevents water infiltration into base layers—the primary cause of pavement failure.

Pothole Repair Techniques for Asphalt

Choose repair methods based on temperature and traffic needs:

| Method | Materials | Lifespan |

|---|---|---|

| Throw-and-Go | Cold patch mix | 3-6 months |

| Semi-Permanent | Hot mix + tack coat | 2-5 years |

| Full-Depth | Compacted aggregate base | 7+ years |

Infrared asphalt repair units now enable seamless patching with 95% density matches to existing pavement.

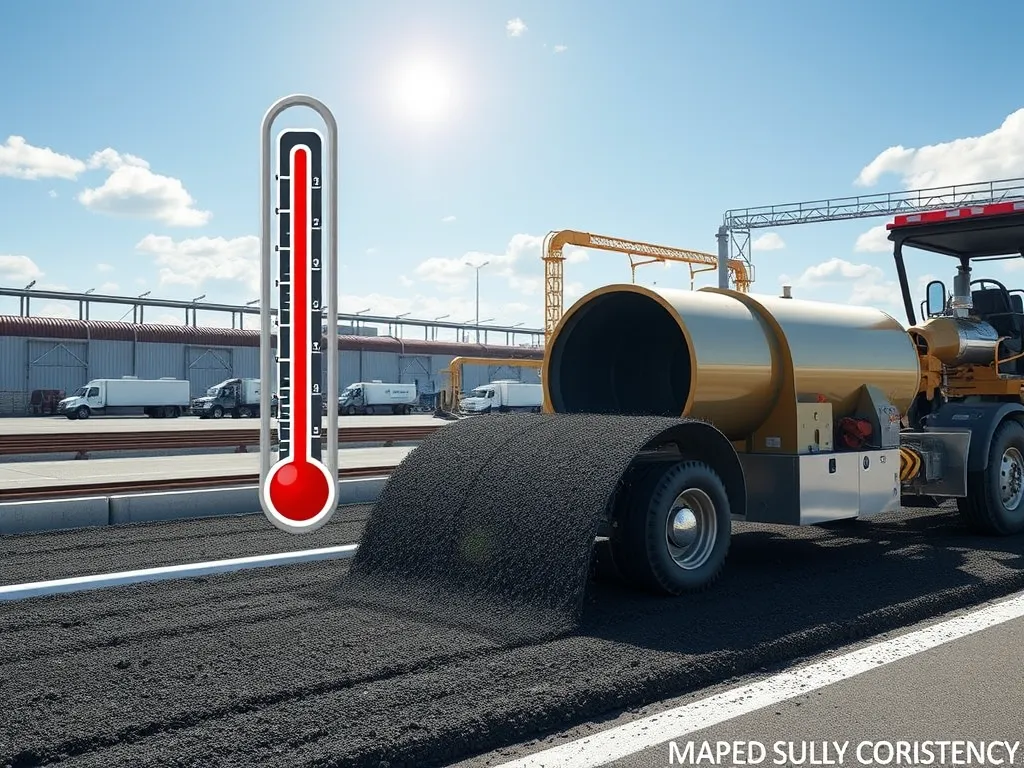

Sealcoating Applications and Best Practices

Apply coal-tar or asphalt-based sealants every 24-36 months. Optimal conditions require:

- Surface temps between 50-85°F

- 48 hours without rainfall

- Proper slurry consistency (85-90 KU viscosity)

Spray systems cover 5,000+ sq ft/hour versus 1,500 sq ft/hour with squeegee methods. Include silica sand additives for traction on driveways.

With these asphalt maintenance practices established, let’s examine specialized care required for residential driveways.

Essential Asphalt Driveway Maintenance Procedures

Consistent care extends pavement life by 25-30 years. Follow these asphalt maintenance guidelines to protect your investment against wear, weather, and weight stress.

Regular Cleaning and Stain Removal Strategies

Pressure wash surfaces every 60-90 days using 1,500-2,500 PSI equipment. Target oil/grease spots within 48 hours with citrus-based degreasers. For stubborn stains:

- Apply poultice cleaners (clay + solvent mixtures) overnight

- Scrub tire marks with trisodium phosphate solutions

- Rinse thoroughly to prevent chemical damage to binders

This asphalt maintenance routine prevents petroleum-based substances from breaking down bitumen bonds.

Edge Maintenance and Reinforcement Methods

Driveway edges bear 40% more stress than central areas. Install 6-inch steel or polymer edging along perimeter lines. Backfill with 3/4-inch crushed stone for drainage. Annual edge sealing with polymer-modified sealants blocks water infiltration – a key factor in 78% of pavement failures.

Seasonal Considerations for Asphalt Driveways

Adjust asphalt maintenance practices for local weather patterns:

- Winter: Use calcium chloride instead of rock salt (reduces surface pitting by 60%)

- Spring: Inspect for freeze-thaw damage; fill cracks wider than 1/8″

- Summer: Schedule sealcoating when temps stay above 50°F

- Fall: Clear leaves to prevent organic acid stains

These asphalt maintenance recommendations set the stage for creating personalized care schedules. Next, learn how to build an asphalt maintenance checklist that aligns with regional climate demands and usage patterns.

Also See: Factors Influencing Asphalt Costs: Save Money Tips

Developing an Effective Asphalt Maintenance Checklist

A solid asphalt maintenance plan stops small issues from becoming costly repairs. Track tasks by season and damage type. Use checklists to stay ahead of wear.

Weekly/monthly Asphalt Inspection Tasks

Walk the site every 7-30 days. Look for cracks wider than 1/4 inch, pooling water, or loose gravel. Clear leaves and trash near drains. Note oil stains needing cleaner. Fix minor cracks fast to block moisture.

Seasonal Crack Prevention Measures

Spring and fall demand crack care. Use rubber-based filler in spring when cracks dry. Apply liquid filler in fall before freeze-thaw cycles start. Cut weeds along edges. Check slopes to keep water flow away from paved areas.

Annual Sealcoating and Resurfacing Guidelines

Sealcoat every 2-3 years at $0.15-$0.25 per sq ft. Resurface if 25%+ of the surface shows wear or base layers stay solid. Pick warm, dry days for work. Let new coats cure 24-48 hours before use.

These asphalt maintenance tips set the stage for smart timing. Next, we’ll break down how often to act based on traffic, weather, and budget needs.

How Often Should You Perform Asphalt Maintenance?

Effective asphalt upkeep relies on timed interventions matched to surface needs. Balance proactive care with budget realities using these asphalt maintenance guidelines.

Factors Influencing Asphalt Maintenance Schedules

Traffic patterns dictate 85% of wear rates. Heavy truck routes need crack sealing every 6-12 months versus 2-3 years for residential driveways. Climate plays a role: freeze-thaw zones require annual inspections, while arid regions extend intervals to 18 months. Sealant type matters too—coal-tar emulsions last 3 years versus 2 years for asphalt-based options. Track surface oxidation rates using penetration tests (ASTM D5 standards) to gauge binder degradation.

Preventative Maintenance Timing for Different Surfaces

| Surface Type | Sealcoating | Crack Repair | Pothole Patching |

|---|---|---|---|

| Driveways | 2-4 years | Annually | As needed |

| Parking Lots | 1-3 years | Twice yearly | Within 72 hours |

| Roadways | N/A | Quarterly | Emergency basis |

High-traffic commercial lots benefit from fog seals every 12-18 months. Use PG (Performance Grade) binders rated for local temperature extremes—PG 64-22 works for most northern states, while PG 70-28 suits southern climates.

Cost-effective Frequency for Budget Planning

Delaying repairs triples rehab costs per NAPA data. Allocate $0.15-$0.35 per square foot annually for basic asphalt maintenance. Schedule major sealcoating during off-peak seasons (late spring/early fall) to save 10-15% on labor. Combine tasks: pair crack filling ($0.50-$1.50/linear foot) with line striping for reduced mobilization fees. Track expenditures against the 80/20 rule—80% of lifespan costs occur in the final 20% of pavement life.

Strategic timing preserves surfaces while managing asphalt maintenance costs. Next, explore specialized care for overlaid pavements requiring compatible repair methods.

Maintenance Tasks for Asphalt Overlay Systems

Overlay systems require specialized care to preserve their structural integrity. These thin surface layers, typically 1.5-2 inches thick, need targeted upkeep to prevent premature failure. Proper maintenance extends overlay lifespan beyond 8-12 years while reducing long-term repair costs by up to 40%.

Resealing Driveways and Parking Lot Overlays

Resealing protects overlays from oxidation and fluid penetration. Use coal-tar or asphalt-based sealants every 2-3 years, applying two coats with squeegee or spray systems. Ensure surface temps stay between 50-85°F during application. Budget $0.15-$0.25 per square foot for professional sealing. Check for raveling or aggregate loss before resealing – these issues require milling prior to treatment.

Joint and Edge Repairs for Overlaid Surfaces

Overlay edges near curbs or expansion joints often fail first. Inspect monthly for voids exceeding 1/4 inch. Repair using hot-pour joint filler (300-350°F application temp) or cold-pour rubberized sealants. Rout cracks to 1:1 width-depth ratio before filling. For severe edge deterioration, install 6-inch-wide fabric reinforcement strips costing $3-$5 per linear foot.

Compatibility Checks With Existing Asphalt Layers

Verify bond strength between overlay and base layers annually. Perform core sampling to check for delamination – acceptable shear strength exceeds 50 psi. Use infrared thermography to detect hidden voids. Ensure overlay mix matches existing pavement’s PG binder grade (e.g., PG 64-22 vs PG 76-22). Mismatched thermal coefficients cause reflective cracking within 18-24 months.

These overlay maintenance practices directly influence stormwater management needs. Properly maintained surfaces reduce polluted runoff by up to 60% compared to degraded pavements.

Environmental Considerations in Asphalt Care

Balancing durability with ecological responsibility shapes modern asphalt maintenance strategies. Green methods protect infrastructure while minimizing environmental impact.

Eco-friendly Sealants and Recycling Practices

Low-VOC (volatile organic compound) sealants replace traditional coal-tar emulsions, cutting airborne pollutants by 60-80%. Many contractors now blend Reclaimed Asphalt Pavement (RAP) into new mixes—the EPA reports 95% recycling rates for asphalt roads. This process slashes material costs 20-35% while conserving natural aggregates.

- Bio-based binders from vegetable oils or pine resin

- Cold-in-place recycling reducing energy use 40%

- Permeable asphalt systems managing 1.5-3 inches of rainfall/hour

Proper Disposal Of Asphalt Maintenance Byproducts

Millings, spent sealants, and degraded binder require regulated handling. EPA guidelines mandate:

- Testing millings for contaminants before reuse

- Sealant waste containment during application

- Landfill bans for recyclable asphalt materials

Many states offer asphalt recycling programs—Minnesota’s MnDOT reuses 1.2 million tons annually in road bases.

Erosion Control and Runoff Management

Unchecked water flow degrades asphalt 300% faster. Install these systems during maintenance:

- Permeable shoulders absorbing 500-800 gallons/day

- Silt fences trapping 80-90% of sediment

- Grassed swales filtering runoff at $2-4 per linear foot

Slope gradients below 2% prevent sheet erosion, while check dams handle steeper grades. Stormwater permits often require pH monitoring for sealant runoff.

These green methods directly influence pavement lifespan—factors like base stability and drainage design determine their effectiveness.

Key Factors Impacting Asphalt Longevity

Long-lasting pavements start with smart planning. Three main components dictate how your asphalt holds up against daily strain and natural forces.

Base Layer Quality and Drainage Design

A strong foundation stops 80% of common asphalt issues. Install a 6-8 inch aggregate base compacted to 95% density for parking lots. Roads need 12+ inches with PG 64-22 binders (asphalt glue) for flexibility. Slope surfaces at 2% minimum to push water away from foundations. Add catch basins every 50-75 ft in high-rain zones.

- Fix pooling water within 48 hours to avoid base saturation

- Inspect ditches and drains twice annually

- Use geotextile fabric under bases in soft soil

Traffic Volume and Weight Distribution Effects

Heavy rigs damage asphalt 8x faster than cars. Limit 18-wheeler parking to zones with 4-inch overlays and 40mm aggregate mixes. Apply these asphalt maintenance practices for high-traffic areas:

- Patch cracks >1/4″ within 2 weeks

- Rotate truck routes to spread wear

- Install 2-inch thick asphalt at loading docks

Bus stops and intersections need 6-month infrared scans to spot weak spots. Budget $0.15-$0.30 per sq.ft. annually for heavy-use zone repairs.

Climate Adaptation for Asphalt Preservation

UV rays and frost cycles crack pavements twice as fast in arid or cold zones. Follow these asphalt maintenance guidelines for climate challenges:

- Hot regions: Apply coal-tar sealants every 3 years

- Cold zones: Use PG 58-34 binders that flex below freezing

- Wet areas: Install porous asphalt with 3/8″ stone voids

Thermal imaging during spring thaw spots 92% of frost-related damage early. Mix in 15% RAP (recycled asphalt) in mild climates to boost crack resistance.

With factors impacting pavement life now clear, a smart asphalt maintenance plan requires knowing what to fix – and when. Up next: building your action list with our asphalt maintenance checklist.

Frequently Asked Questions

What Are Common Signs That Asphalt Needs Maintenance?

Look for cracks larger than 1/4 inch, potholes, surface raveling, or ponding water, which suggest that maintenance is needed. Regular visual inspections can help identify these issues early.

Can Climate Impact the Frequency Of Asphalt Maintenance?

Yes, extreme weather conditions such as freeze-thaw cycles in colder climates or intense UV exposure in hotter areas can accelerate wear. Therefore, maintenance schedules may need to be adjusted according to local climate conditions.

What is the Difference Between Crack Sealing and Crack Filling?

Crack sealing is typically used for larger, active cracks that might still be moving, while crack filling is for smaller, stationary cracks. The methods differ in terms of the materials used and the application process.

What is the Best Time Of Year for Sealcoating Asphalt?

The ideal time for sealcoating is during warmer months, typically between late spring and early fall, when temperatures are consistently above 50°F and there is minimal chance of rain.

How Can I Extend the Lifespan Of My Asphalt Surface?

Regular maintenance, including timely crack sealing, sealcoating, cleaning debris, and managing drainage, can significantly prolong the lifespan of your asphalt surface. Additionally, minimizing heavy traffic and implementing proper drainage can also help.

Are There Eco-friendly Options for Asphalt Maintenance?

Yes, consider using low-VOC sealants, recycled asphalt pavement (RAP), and bio-based binders to make your asphalt maintenance more environmentally friendly. Many new products aim to reduce environmental impact while maintaining performance.

What Maintenance is Recommended for High-traffic Areas?

For high-traffic areas, it is recommended to conduct regular inspections and maintenance every 3-6 months, ensure timely pothole repairs, and apply sealcoating more frequently to protect against wear and tear from constant use.

Can I Do Asphalt Maintenance Myself, or Should I Hire a Professional?

While some tasks like cleaning can be done by homeowners, most maintenance tasks like crack sealing, pothole repairs, and sealcoating are best left to professionals to ensure quality and longevity of repairs.

Closing Thoughts

Regular asphalt maintenance is vital for enhancing the durability and aesthetic appeal of your surfaces. Consistent care can prevent costly repairs and extend the lifespan of your pavement. By implementing the guidelines discussed, you can tackle issues like cracking, potholes, and wear effectively.

Creating an organized maintenance schedule ensures that your asphalt stays in the best shape possible. Remember to assess factors like climate, traffic, and surface type when planning. A proactive approach not only saves money but also contributes to safer driving conditions.

For more information on maintaining your asphalt surfaces, visit Asphalt Calculator USA. We’re here to help you make informed decisions to keep your asphalt looking and performing its best.