Fatigue Testing Methodologies for Asphalt: How Roads Stand the Test Of Time

Published on: December 16, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Fatigue testing methodologies measure how asphalt breaks down under repeated stress from traffic loads, temperature changes, and weather. These tests differ from single-load assessments by simulating years of wear in controlled lab settings. Engineers use three main approaches – stress-based, strain-based, and hybrid methods – to predict when cracks will form and how quickly they’ll spread. Common tools include Universal Testing Machines (UTMs that apply precise forces) and environmental chambers replicating freezing winters or scorching summers. Key standards like ASTM D7460 and AASHTO T321 ensure consistent testing across highway projects and airport runways.

This guide breaks down how fatigue testing works in real-world scenarios. You’ll learn the differences between four-point bending tests and uniaxial strain protocols. We’ll explore how 100,000+ load cycles get compressed into 72-hour lab sessions using hydraulic actuators. Data sections explain S-N curves (stress-life graphs showing failure points) and why phase angle measurements matter. For pavement designers, we’ll cover moisture impact simulations, temperature swing tests (-40°F to 160°F), and cost-effective prep methods for Marshall specimens.

Contents

- What is Fatigue Testing in Asphalt?

- Key Objectives Of Fatigue Testing in Asphalt

- Common Fatigue Testing Methods for Asphalt

- Essential Equipment for Asphalt Fatigue Testing

- Critical Testing Standards for Asphalt Fatigue

- Test Procedures and Data Interpretation

- Best Practices for Asphalt Fatigue Testing

- Environmental Considerations in Asphalt Fatigue

- FAQs: Asphalt Fatigue Testing

- Closing Thoughts

- Additional Resources for You:

What is Fatigue Testing in Asphalt?

Fatigue testing measures how asphalt mixtures withstand repeated stress from traffic loads and temperature changes. These tests simulate years of wear in controlled lab settings, helping engineers pinpoint when cracks start and spread. The process feeds critical data into pavement design systems like Superpave, which optimizes asphalt mixes for specific climates.

Definition and Purpose

Fatigue testing method refers to applying cyclic loads to asphalt samples until failure occurs. Labs use hydraulic actuators or Universal Testing Machines to replicate truck traffic impacts. Tests run at strain levels between 50-500 microstrains, matching real-road conditions. The goal? Quantify how many load cycles a mix endures before cracks form—key for grading materials in high-traffic zones like interstate highways.

Role in Predicting Asphalt Pavement Lifespan

By analyzing failure patterns, engineers build S-N curves (stress vs. cycle count) that forecast pavement durability. A mix lasting 1 million cycles at 200 microstrain might serve 15+ years on a busy highway. Tests also factor in variables like PG binder grades and aggregate angularity. For instance, polymer-modified binders can boost fatigue life by 40% compared to standard asphalt. This data directly informs AASHTOWare Pavement ME design software, reducing premature cracking risks.

These predictive models help agencies allocate budgets—prioritizing fatigue-resistant mixes for truck routes while using cost-effective options for local roads. Up next: How test results translate into actionable strategies for pavement longevity.

Key Objectives Of Fatigue Testing in Asphalt

Fatigue tests check how asphalt acts under stress. They aim to spot weak points before roads fail. Three main goals guide these checks.

Evaluating Material Durability

Tests show how long asphalt lasts under repeated loads. Labs use load cycles (like 106 passes) to mimic traffic wear. Key metrics track stiffness loss – good mixes keep over 80% strength after 50k cycles. Binder type (PG 64-22 vs PG 76-16) changes results by 30-40%.

Assessing Crack Propagation Resistance

Notch tests measure crack speed in samples. A 10mm cut grows faster in poor mixes – up to 0.5mm/cycle. Tests use Paris’ law math: da/dN = C(ΔK)n. Top mixes need 2-3x more force to spread cracks than standard ones.

| Mix Type | Crack Growth Rate (mm/cycle) |

|---|---|

| High-Polymer | 0.12 |

| Standard | 0.34 |

| Recycled | 0.41 |

Validating Pavement Design Models

Lab data feeds tools like AASHTOWare Pavement ME. If tests show 50k cycles to fail, but models predict 52k, teams tweak inputs. Field cores vs lab samples must match within 15% error. Calibration factors (0.8-1.2) adjust for local traffic or weather.

These test goals shape how we build roads that last. Next, we’ll break down the top fatigue test methods used today.

Common Fatigue Testing Methods for Asphalt

Engineers rely on three core strategies to measure how asphalt degrades under repeated loads. Each fatigue testing method simulates real-world stresses while tracking crack formation.

Stress-based Fatigue Testing

These protocols apply fixed force levels to specimens until failure. Results help predict pavement longevity under heavy traffic loads.

Constant Stress Amplitude Method

This fatigue test method subjects samples to uniform stress cycles, typically between 10 Hz to 30 Hz. The process continues until cracks reach 50% of the specimen’s width. Data plots cycles-to-failure against stress levels, creating S-N curves specified in ASTM D7460.

Four-Point Bending Test for Asphalt

Beams undergo flexural stress through four contact points, replicating road bending under truck traffic. Hydraulic actuators apply loads up to 10 kN while strain gauges track micro-crack growth. This testing methodology for fatigue helps determine flexural stiffness loss over 1 million cycles.

Strain-based Fatigue Testing

Instead of fixed force, these fatigue evaluation methods control deformation levels. Useful for studying thermal cracking in cold climates.

Controlled-Strain Flexural Testing

Specimens get cyclically bent at 0.1% to 0.5% strain levels. Tests run until stiffness drops by 50%, with phase angle shifts indicating internal damage. Requires environmental chambers set to -20°C for winter condition simulations.

Uniaxial Strain-Controlled Protocols

Vertical strain gets applied to cylindrical cores using servo-pneumatic systems. Measures energy dissipation per cycle – higher values signal faster fatigue failure. Commonly used with PG 64-22 binders in AASHTO T321 tests.

Hybrid Methodologies

Combining stress-strain parameters improves simulation of complex road conditions. These fatigue test techniques account for both traffic loads and temperature swings.

Combined Stress-Strain Approaches

Applies dynamic stress while limiting maximum strain. Dual-control systems adjust loads based on real-time deformation feedback. Mimics seasonal changes where summer heat softens pavement, requiring lower stresses to maintain set strains.

Notch-Induced Fatigue Evaluation

Pre-cut notches (2-5 mm deep) trigger controlled cracking. Digital image correlation tracks crack speed under cyclic loads. Helps quantify fracture energy – critical for mixes using recycled asphalt shingles (RAS) up to 5% content.

Matching the right fatigue testing standard to project needs requires weighing traffic volume, climate, and mix designs. Next, we’ll examine the specialized tools that make these measurements possible.

Also See: Evaluating the Efficiency Of Electrical Heating for Asphalt

Essential Equipment for Asphalt Fatigue Testing

Precise tools form the backbone of reliable fatigue testing. Three core components dominate modern labs studying pavement endurance under repeated stress.

Universal Testing Machines (Utms)

UTMs serve as workhorses for executing fatigue test methods. These systems apply controlled cyclic loads through load frames rated for 100-500 kN. Equipped with digital controllers, they run stress-based or strain-based protocols per ASTM D7460. Modern variants integrate data loggers tracking 1,000+ data points per second during bending tests. Key metrics include load cycles to failure, stiffness degradation rates, & crack initiation thresholds.

Hydraulic-powered Actuators

High-force actuators drive precise load delivery in fatigue test techniques. Servo-hydraulic models generate forces up to 250 kN at frequencies reaching 25 Hz—mimicking heavy truck traffic impacts. Built-in LVDTs measure displacements within 0.001 mm resolution. Such precision proves vital when testing modified binders or recycled mixes prone to early-stage microcracking.

Environmental Conditioning Chambers

Temperature-regulated chambers simulate field conditions during fatigue protocol execution. Units maintaining -40°F to 300°F test thermal cracking resistance per AASHTO T321. Some chambers cycle humidity from 10% to 95%, replicating seasonal moisture damage. Advanced models combine UV exposure with mechanical loading to study combined weathering-fatigue effects on PG-graded binders.

Proper equipment setup bridges lab tests with real pavement performance. Next, standardized procedures ensure consistent results across different fatigue evaluation methods.

Critical Testing Standards for Asphalt Fatigue

Global groups set strict rules to test how asphalt holds up over time. Three key specs shape modern fatigue checks.

ASTM D7460: Standard Test Method for Fatigue

This US-based method tests how asphalt lasts under repeated stress. Cyclic loads push samples to failure at set stress levels. Labs track cycle counts until cracks form. Key factors: load speed (1-10 Hz), test temp (5-30°C). Data plots stress vs. cycles (S-N curve) to rank mix life.

AASHTO T321: Beam Fatigue Specification

This beam test bends asphalt slabs to mimic road strain. Four-point setups apply strain while tracking stiffness loss. Specs demand 380 mm beams, tested at 20°C with 10 Hz loads. This method helps predict how long roads last under heavy trucks.

EN 12697-24: European Bending Tests

Europe’s go-to spec uses trapezoid samples in bend tests. Machines cycle loads until cracks split the slab. Tests run at 0.1 Hz, 10°C to match cold climates. This check rates crack growth speed in mixes used in freeze-thaw zones.

These global specs form the base for field tests. Next, we break down how to run tests and read the data.

Test Procedures and Data Interpretation

Accurate analysis of asphalt fatigue behavior demands precise test execution and smart data handling. Modern techniques blend mechanical testing with advanced analytics to predict pavement performance under real-world stresses.

Developing S-N Curves for Asphalt Mixes

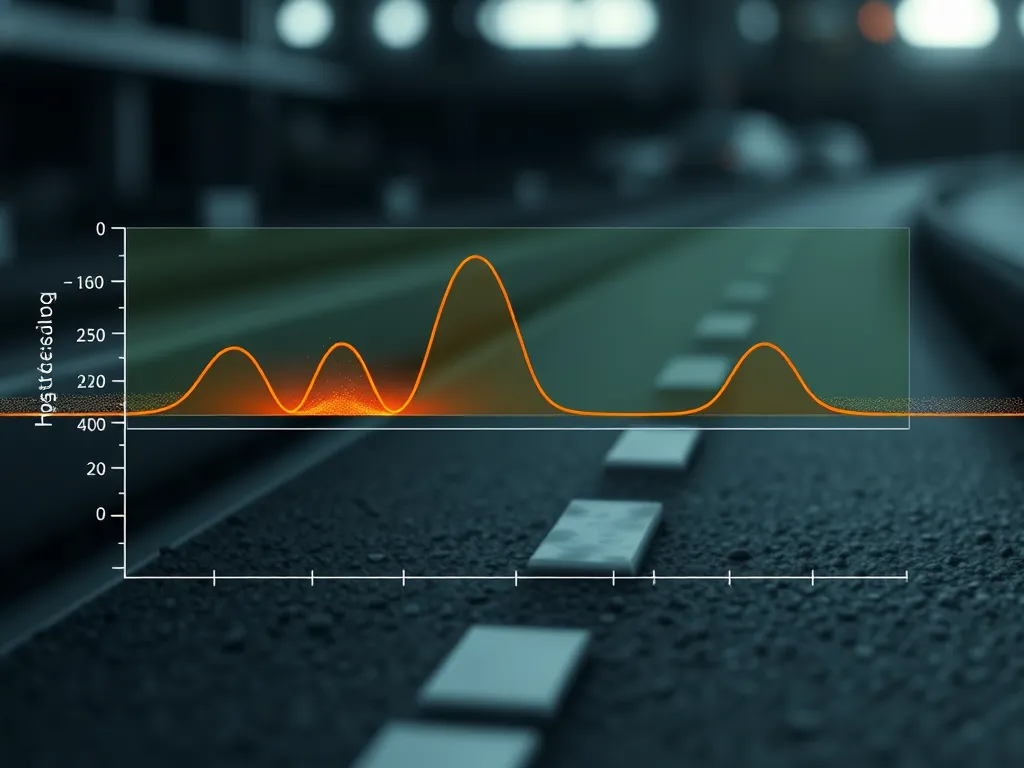

S-N curves (stress vs. cycles-to-failure graphs) form the backbone of fatigue life prediction. Engineers plot applied stress (MPa) against log-scale load cycles using results from four-point bending tests or uniaxial protocols.

Stress-Life Relationship Analysis

This fatigue test method correlates stress levels with failure cycles. For PG 64-22 binder mixes, typical curves show 10^6 cycle endurance limits at 0.5-1.2 MPa. Temperature variations (±2°C) can shift results by 18-23%, requiring strict lab controls.

Cycle Counting Methods

Rainflow counting dominates asphalt fatigue testing standards, identifying critical load sequences in variable-amplitude tests. ASTM D7460 mandates this approach for analyzing traffic-pattern simulations, filtering out non-damaging cycles below 0.3 MPa.

Phase Angle Measurement Techniques

Dynamic shear rheometers track phase angles (δ) between stress and strain in viscoelastic asphalt. Fatigue-prone mixes show δ increases exceeding 5° during 50,000 cycles. The AASHTO T321 protocol specifies 10Hz measurements with 0.01° resolution for beam specimens.

Dissipated Energy Approach

This fatigue evaluation method calculates energy loss per cycle using hysteresis loop areas. Studies show mixes failing at 35-50 kJ/m³ cumulative dissipation. The method excels in comparing modified binders – SBS polymers typically boost energy capacity by 40% versus neat asphalt.

Mastering these fatigue test techniques directly informs pavement design. Next, proper equipment setup and calibration determine whether field performance matches lab predictions.

Best Practices for Asphalt Fatigue Testing

Proper test setup boosts result trust. Follow these steps to cut errors and boost lab-to-field match rates.

Specimen Preparation Guidelines

Test slabs need tight air void control. Use a gyratory compactor at 1.25° angle for mix denseness. Target 4-7% air voids per AASHTO T 312. Cut samples with diamond saws to keep edges sharp. Cure all slabs 24 hours at 73°F before tests. Check surfaces with laser scans for flat spots over 0.04 inches.

Temperature Control Protocols

Set test temps to match road site highs. Use enviro-chambers with ±1°F accuracy. For most mixes, run tests at 68°F (20°C) to mimic spring stress cycles. Pre-cool hot-mix slabs at 3°F per hour to dodge thermal cracks. Track core temps with probes per ASTM D6648. Cold regions may need tests at 32°F with anti-ice pads.

| Climate Zone | Test Temp Range | Soak Time |

|---|---|---|

| Hot | 104-122°F | 6 hours |

| Moderate | 68-86°F | 4 hours |

| Cold | 14-32°F | 8 hours |

Loading Frequency Optimization

Match load speed to real traffic. For highways, use 10 Hz sine waves. City roads need 2-5 Hz. Watch for heat build-up past 15 Hz – it skews phase angles. SHRP studies show 5-10 Hz gives best life forecasts. Adjust rates for stiff mixes like PG 76-22 versus soft PG 64-22 binders.

These core steps set the stage for valid tests. Next, we’ll see how sun, rain, and time change the game.

Environmental Considerations in Asphalt Fatigue

Real-world pavement performance depends on environmental factors not captured in lab tests. Modern fatigue testing methodology for fatigue must account for moisture intrusion, temperature swings, and material aging.

Moisture Sensitivity Testing

Water infiltration causes 70% of premature asphalt failures. The Modified Lottman test (AASHTO T 283) measures moisture damage resistance by subjecting compacted samples to vacuum saturation, freeze-thaw cycles, and 140°F conditioning. Results show as tensile strength ratios – mixes below 80% fail fatigue testing standards for moisture-prone areas.

Thermal Cycling Impacts

Daily temperature shifts (-20°F to 120°F) create internal stresses through expansion/contraction. Fatigue test methods like the Thermal Stress Restrained Specimen Test (TSRST) apply 100+ freeze-thaw cycles while monitoring crack formation. Polymer-modified binders withstand 2-3× more cycles than conventional PG 64-22 asphalt in these protocols.

Aging Simulation Methods

UV exposure and chemical changes stiffen asphalt over time. Rolling Thin Film Oven Tests (RTFOT) mimic 5-10 years of aging in 85 minutes at 325°F. For long-term analysis, Pressure Aging Vessel (PAV) treatments run 20 hours at 230°F. Aged samples tested under ASTM D7460 show 40-60% faster crack growth in strain-controlled fatigue evaluation methods.

Accounting for these factors separates basic fatigue test techniques from true performance modeling. Up next: answering frequent queries about fatigue testing methods and their practical applications.

FAQs: Asphalt Fatigue Testing

What Are the Primary Methods Of Fatigue Testing for Asphalt?

The primary methods of fatigue testing for asphalt include stress-based, strain-based, and hybrid methodologies. Stress-based methods focus on applying fixed loads until failure, while strain-based methods control the deformation experienced by the material. Hybrid methodologies blend both approaches to mimic complex real-world conditions.

How Does the Four-point Bending Test Work for Asphalt?

The four-point bending test subjects asphalt beams to stress at four contact points, allowing engineers to evaluate how the material behaves under bending loads. It tracks the specimen’s performance as it undergoes repeated load cycles, which helps determine its fatigue life and stiffness degradation.

What Does an S-N Curve Show in Asphalt Fatigue Analysis?

An S-N curve, or stress-life curve, illustrates the relationship between the applied stress levels and the number of cycles to failure for asphalt samples. It provides critical insights into how different asphalt mixes perform under repeated loading over time, thus helping engineers predict the longevity of pavement materials.

What Equipment is Essential for Basic Fatigue Testing?

Essential equipment for basic fatigue testing includes Universal Testing Machines (UTMs), hydraulic-powered actuators, and environmental conditioning chambers. UTMs apply controlled loads, while hydraulic actuators simulate real traffic conditions, and environmental chambers replicate various temperature and humidity levels that asphalt would encounter in the field.

Closing Thoughts

Fatigue testing methodologies play a pivotal role in ensuring the longevity and reliability of asphalt pavements. Understanding the various testing methods, from stress-based to strain-based approaches, allows engineers to select the most suitable techniques for their projects. By evaluating material durability and crack propagation resistance, engineers can predict pavement lifespan and enhance design models.

Adhering to critical standards like ASTM D7460 and AASHTO T321 ensures consistency and reliability in testing outcomes. As technology advances, incorporating hybrid methodologies and optimizing environmental considerations become vital for accurate assessments. This comprehensive approach not only leads to safer roads but also supports sustainable practices in construction.

For more insights on asphalt performance and related resources, visit Asphalt Calculator USA.