What Determines Your Asphalt Repair Method?

Published on: December 16, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Selecting asphalt repair techniques involves analyzing seven key factors: material types, damage severity, weather patterns, project size, budget limits, local rules, and environmental impact. These elements determine whether you use fast cold patches for minor cracks or invest in infrared repairs for seamless results. A 2-inch surface crack might only need sealant, while a 6-inch pothole with base damage requires full-depth excavation. Contractors often weigh immediate costs against lifespan – temporary fixes average $0.50-$2.50 per square foot versus $3-$8 for permanent solutions.

This guide breaks down how each factor shapes repair decisions. You’ll see why using hot mix asphalt (HMA) fails below 50°F and how recycled asphalt pavement (RAP) cuts material costs by 20-30%. We’ll compare methods like spray injection for subsurface voids versus mill-and-fill for worn surfaces. Learn how state DOT compaction standards (usually 92-96% density) affect technique choices and why rainy regions favor cold-applied binders. From driveway touch-ups to highway overhauls, these criteria ensure durable, compliant repairs.

Contents

- Material Properties Of Asphalt Mixes

- Type and Severity Of Asphalt Damage

- Environmental and Seasonal Conditions

- Project Scale and Time Constraints

- Cost and Resource Considerations

- Regulatory Compliance Requirements

- Surface Preparation Demands

- Repair Technique Capabilities

- Contractor Expertise Evaluation

- Environmental Impact Considerations

- FAQ: Asphalt Repair Technique Selection

- Closing Thoughts

- Useful References for You:

Material Properties Of Asphalt Mixes

Mix composition directly shapes repair method performance. From binder viscosity to stone grading, material traits dictate which fixes hold under traffic or freeze-thaw cycles.

Types Of Asphalt Mixes (Hot Mix Vs. Cold Mix)

Hot mix asphalt (HMA) requires heating to 300°F-350°F during production. Used for structural repairs on highways, its high density resists rutting. Cold mix stays pliable at ambient temps, suited for temporary pothole fixes in winter. Contractors weigh project timelines against traffic needs – HMA needs 2-4 hours to cool, while cold mix allows immediate use.

| Mix Type | Cost per Ton | Ideal Use Case |

|---|---|---|

| Hot Mix | $80-$120 | High-traffic roads, temps >40°F |

| Cold Mix | $60-$90 | Emergency repairs, temps <50°F |

Impact Of Aggregate Size on Repair Durability

Stone size in the mix affects load distribution. Aggregates larger than 1/2” (12.5mm NMAS) create interlocking friction for heavy truck lanes. Smaller 3/8” (9.5mm NMAS) stones fill shallow cracks without compromising ride smoothness. Mismatched sizes cause uneven compaction – a common reason for premature raveling.

Binder Quality and Climate Compatibility

Performance-graded (PG) binders must match regional weather. PG 64-22 works in zones with winter lows of -22°F, while PG 76-16 handles southern heat up to 76°F. Poor binder grading leads to thermal cracking or bleeding. Testing penetration (40-50 dmm) and softening point (115°F-140°F) ensures the binder won’t fail under local conditions.

With material traits shaping repair outcomes, the next step involves matching these properties to observed pavement distress types.

Type and Severity Of Asphalt Damage

Damage classification drives repair decisions. Matching techniques to specific failure modes ensures lasting results while cutting costs by 15-40%.

Potholes Vs. Surface Cracks: Technique Variations

Potholes demand structural fixes like full-depth patching with hot mix asphalt (HMA). Surface cracks under ¼” width get seal coats. Alligator cracks exceeding 2″ depth require infrared asphalt repair or mill-and-fill. Spray injection works for potholes below 50°F when HMA plants close.

| Damage Type | Repair Methods | Material Options |

|---|---|---|

| Potholes | Throw-and-roll, spray patching | Cold mix, HMA |

| Edge cracks | Routing + sealant | CRF-2 emulsion |

| Alligator cracks | Infrared heater + compaction | RAP blends |

Depth and Width Of Damage As Selection Criteria

Shallow surface defects (<2") permit skin patching. Depths exceeding 4" trigger full-depth repairs with aggregate base replacement. Widths over ½" need joint sealing to block water infiltration. The Asphalt Institute recommends milling 1.5x the crack width for proper filler adhesion.

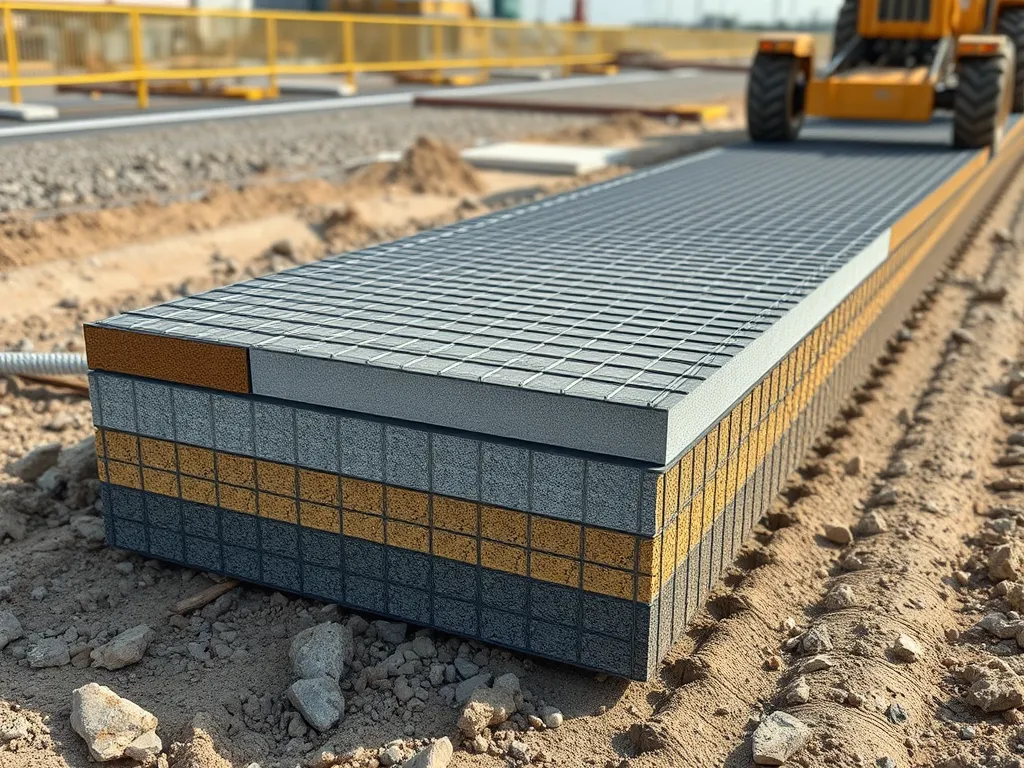

Base Layer Integrity Assessment

Failed base layers (CBR < 80) require stabilization before surface repairs. Core samples and DCP tests identify compromised subgrades. Techniques like full-depth reclamation mix 6-12" of existing pavement into new base material. Geogrid reinforcement adds $0.50-$1.25 per sq.ft. but extends repair life by 3-5 years.

With damage characteristics mapped, environmental factors like temperature swings and rainfall patterns further refine method selection.

Environmental and Seasonal Conditions

Weather patterns and climate directly shape repair method selection. Temperature swings, precipitation levels, and curing environments dictate which techniques work – and which fail.

Temperature Requirements for Hot Mix Applications

Hot mix asphalt demands precise heat ranges for proper compaction. Installers need ground temps above 50°F and mix temperatures between 275-325°F during placement. Below 45°F, binder viscosity drops 60%, creating weak bonds. Northern states like Minnesota often stockpile PG 58-28 binders for cold-weather flexibility.

Moisture Sensitivity in Cold Weather Repairs

Water infiltration ruins 30% more cold patches than hot mixes during freeze-thaw cycles. Contractors combat this with polymer-modified emulsions or cutting grooves for drainage. Infrared heaters pre-dry surfaces in damp conditions – a $75/hour rental that prevents 80% of moisture-related failures.

Curing Time Constraints in Rain-prone Areas

Seattle road crews face 152 rainy days annually, forcing tough choices. Full-depth patches needing 72-hour cure times get replaced with spray-injection repairs hardening in 20 minutes. Quick-set additives like TrowelPave accelerate curing by 40%, though they add $12 per square yard.

These weather-driven decisions set the stage for weighing project scale against tight deadlines – critical factors when traffic lanes hang in the balance.

Also See: Comparison Of Natural and Recycled Aggregates

Project Scale and Time Constraints

Repair method choice factors pivot on project size and urgency. A 500-square-foot parking lot repair demands different tactics than a 10-mile highway rehabilitation. Tight deadlines often override ideal technical solutions.

Small-scale Patching Vs. Full-depth Repairs

Cold mix asphalt works for potholes under 2″ deep, costing $1.50-$3.00 per square foot. Full-depth repairs require saw-cutting 8″-12″ layers, HMA (Hot Mix Asphalt), and compactors – tripling costs. Structural failures below the surface course mandate full excavation to prevent recurring damage.

Traffic Disruption Considerations

Urban arterial roads handling 20,000+ vehicles daily often use spray injection patching (15-minute fixes) instead of traditional milling. Night work with quick-set asphalt emulsions minimizes lane closure fines – DOT penalties can exceed $5,000 per hour in metro areas. Traffic volume thresholds directly determine repair technique selection criteria.

Cure Time Vs. Road Reopening Deadlines

Cold patch asphalt allows immediate traffic but lasts 6-18 months. Hot mix needs 4-6 hours curing at 275°F for 95% compaction density. Projects under federal funding often specify warm-mix asphalt additives like Evotherm® that cut curing to 45 minutes. Cure windows clash with deadlines when repairing airport runways needing 8,000 PSI strength within 12-hour operational gaps.

These operational pressures set the stage for evaluating financial impacts – where equipment rentals and material waste dramatically sway project viability.

Cost and Resource Considerations

Selecting repair methods requires balancing upfront expenses with resource efficiency. Contractors weigh equipment needs, future upkeep costs, and material usage patterns to align techniques with project budgets.

Equipment Availability for Specific Techniques

Specialized machinery often dictates method feasibility. Infrared asphalt heaters for seamless patching or spray injection units for deep repairs require significant capital investment. Contractors lacking these assets may default to cold mix applications or traditional throw-and-roll pothole fixes, even if less durable. Rental costs for milling machines ($250-$400 daily) can sway decisions toward simpler solutions.

Long-term Maintenance Cost Projections

Life-cycle cost analysis separates temporary fixes from lasting solutions. While crack sealing costs $0.15-$0.35 per linear foot initially, full-depth repairs at $3-$5 per square foot prevent recurrent base failures. Agencies track 10-year cost curves showing mill-and-fill operations typically outlast surface treatments by 7-9 years despite higher initial pricing.

Material Waste Minimization Strategies

Recycled Asphalt Product (RAP) integration cuts virgin material use by 30-50% in overlays. Precise volumetric calculations for infrared patches reduce leftover mix. Cold planing practices salvage 95% of existing pavement for reuse, aligning with lean construction principles. Advanced software now predicts exact tonnage needs within 2% variance for common repair types.

These financial and logistical factors intersect with legal standards shaping repair quality. Up next: how regulatory frameworks govern technique selection.

Regulatory Compliance Requirements

Local and federal regulations directly shape repair method decisions through enforceable technical mandates. Contractors must balance project goals with strict adherence to codes governing materials, slopes, and worksite safety.

DOT Specifications for Asphalt Repairs

State DOTs enforce specific repair protocols. Pennsylvania requires PG 64-22 binder for hot mix patches in freeze-thaw zones. Texas mandates minimum 3-inch depth for spray injection repairs on highways. Non-compliance risks penalties up to $15k/day. These rules eliminate certain techniques – like cold mix on high-traffic roads – from consideration.

Slope and Drainage Standards

Repairs must maintain 2% minimum cross-slope for drainage. Steeper 4-6% slopes near curbs dictate milling depth. Techniques like infrared patching preserve original slope profiles better than manual methods. Projects in flood zones require permeable asphalt or underdrains – adding 18-35% to base costs.

Safety Marking and Site Preparation Rules

MUTCD standards require specific traffic control: 8-foot buffer zones, retroreflective signs, and 48-hour advance notice for lane closures. These factors affect method selection – spray patching needs 15-minute closures versus 4-hour full-depth repairs. Cities like Chicago now mandate 30% recycled content in all public works patches.

Meeting these requirements sets the stage for the next critical phase: preparing surfaces to withstand both weather and weight.

Surface Preparation Demands

Proper groundwork forms the foundation for long-lasting asphalt fixes. Surface prep quality directly impacts repair method choice, with distinct protocols shaping installation success and lifespan.

Cleaning and Degreasing Protocols

Oil stains or dirt reduce bond strength by up to 60%. High-pressure washing (2,500-3,500 PSI) removes loose debris, while solvent-based cleaners tackle petroleum residues. Projects involving polymer-modified mixes demand ISO 8501-1 Sa2.5 cleanliness standards – a key factor in selecting infrared thermal patching over cold pour methods.

Tack Coat Application Requirements

This bitumen emulsion layer boosts adhesion between old and new asphalt layers. Spray rates vary from 0.05-0.15 gallons per square yard based on pavement porosity. Hot mix overlays require tack coats heated to 140-160°F for optimal viscosity. Contractors choosing mill-and-fill operations must account for 24-hour curing before traffic loading.

Edge Sealing for Crack Repairs

Routing 1/4″ wide channels along crack edges allows sealants to form mechanical locks. Rubberized asphalt sealants applied at 375°F create waterproof barriers, critical when fixing alligator cracks in freeze-thaw zones. Proper edge prep extends crack repair lifespan from 2 to 7+ years – a major determinant in spray-injection versus saw-and-patch decisions.

With surface conditions optimized, focus shifts to matching repair tactics to specific material capabilities…

Repair Technique Capabilities

Selecting the right asphalt repair method depends on each technique’s strengths. Project managers weigh factors like damage depth, material compatibility, and equipment needs to match solutions to specific pavement flaws.

Infrared Asphalt Patching Applications

Heat-based patching excels at fixing surface-level flaws under 2″ deep. This method recycles existing pavement by heating it to 300°F-350°F, creating seamless bonds. Best for alligator cracks or minor edge defects. Key selection criteria: ambient temperatures above 50°F and dry weather conditions.

Spray Injection for Deep Subsurface Repairs

For voids reaching 8″ below the surface, spray systems blast aggregate and emulsion into damaged areas using 100-150 psi compressed air. Tackles potholes with compromised base layers. Requires specialized rigs costing $75,000-$120,000. Project scale and traffic closure windows often determine this choice.

Overlay Vs. Mill-and-fill Decisions

Two approaches address widespread wear:

- Overlay: Adds 1.5″-3″ new layer over existing pavement. Only viable when existing surface has ≤25% cracks

- Mill-and-Fill: Removes 1″-6″ old asphalt before replacement. Used for rutted or uneven surfaces

Cost differentials of $2.50-$4.50 per square foot often drive final decisions.

After selecting techniques based on these capabilities, attention shifts to contractor qualifications – the next vital piece of the repair puzzle.

Contractor Expertise Evaluation

Contractor capabilities directly shape repair method selection. Teams with niche skills or advanced tools unlock techniques others can’t execute. Let’s break down three key evaluation points.

Specialization in Specific Repair Methods

Contractors often excel at particular methods. A crew trained in spray injection can tackle deep base failures, while infrared specialists fix surface voids without seams. For example, spray injection requires precise emulsion mixing ratios (typically 0.5-1.5% polymer modifiers) to stabilize road bases. Specialized teams achieve 30% faster project completion on average versus generalists.

Equipment Fleet Quality Assessment

Modern gear expands repair options. Check for:

| Equipment Type | Impact |

|---|---|

| Infrared heaters | Enables seamless thermal patching |

| Cold planers | Allows precise milling to 6-inch depths |

| Pavement recyclers | Processes 90% RAP mixes for eco-repairs |

Outdated machinery limits method choices and compromises compaction rates below 92% density.

Warranty Offerings for Different Techniques

Warranty terms signal confidence in method durability. Contractors typically back infrared repairs for 5+ years versus 1-2 years for cold patches. Longer warranties often align with techniques like full-depth reclamation, where binder-rich mixes (PG 76-22) resist thermal cracking. Always cross-check warranty exclusions for freeze-thaw cycles or heavy truck traffic.

Next, we’ll explore how environmental regulations steer method choices toward sustainable options.

Environmental Impact Considerations

Environmental factors weigh heavily when selecting repair methods. Regulations push teams to balance durability with eco-conscious practices. Three key elements shape these decisions.

Recycled Asphalt Product (RAP) Usage

RAP content directly influences technique selection. High RAP mixes (30-50%) often require specialized equipment like parallel drum plants. Many state DOTs mandate 20% minimum RAP for surface courses. Cold-in-place recycling avoids hauling waste, cutting embodied carbon by 15-20%. Contractors must verify binder compatibility when blending aged vs. virgin bitumen.

Emissions From Hot Mix Production

Hot mix emits 0.03-0.05 tons of CO₂ per ton produced at 300°F. This pushes urban projects toward warm mix additives (Evotherm® or Sasobit®) lowering temps by 50°F. Infrared patching emits 60% less than traditional hot methods. Emission caps under EPA’s Tier 4 standards may dictate equipment choices for large-scale repairs.

Runoff Management During Repairs

Techniques must prevent polycyclic aromatic hydrocarbons (PAHs) from entering waterways. Permeable patching mixes (30% void space) reduce stormwater surges. Silt fences or check dams become non-negotiable in repairs near wetlands. Compliance with NPDES permits (40 CFR part 122) affects method speed and material selection.

Balancing ecological mandates with functional needs shapes repair strategy viability. Up next: how project scale and deadlines further narrow options.

FAQ: Asphalt Repair Technique Selection

How Does Climate Affect Crack Sealing Method Choice?

Climate plays a critical role in the choice of crack sealing methods. In warm climates, hot pour sealants are often preferred as they provide better elasticity and adhesion. Conversely, colder regions may benefit from cold pour sealants that are more suitable for low temperatures, as they prevent cracking from thermal shifts.

When is Cold Mix Preferred Over Hot Mix Asphalt?

Cold mix is typically preferred in emergency situations or in cooler weather when hot mix cannot be utilized due to temperature restrictions. It is also beneficial for temporary repairs where immediate traffic use is necessary, despite its shorter lifespan compared to hot mix asphalt.

What Determines Milling Depth for Pavement Repairs?

Milling depth is primarily determined by the severity of the pavement distress. Repairs often require milling 1 to 2 inches for surface-level defects, while deeper structural failures may necessitate milling depths of 3 inches or more, depending on the existing pavement condition and intended repair strategy.

How Long Should Traffic Avoid Fresh Asphalt Repairs?

Fresh asphalt repairs usually require a curing period during which traffic should be restricted. For hot mix repairs, this can typically range from 4 to 6 hours, while cold mix applications allow for immediate traffic. However, it’s crucial to follow specific contractor or manufacturer recommendations to ensure proper curing.

Closing Thoughts

Selecting the right asphalt repair technique involves many crucial factors. Material properties, the type of damage, and environmental conditions all play a significant role in determining the best method. Project scale, cost considerations, and regulatory compliance cannot be overlooked either. Each factor intertwines, making a thorough analysis vital for success.

Contractor expertise is another important consideration. A skilled contractor will assess the situation accurately, recommend appropriate techniques, and ensure adherence to safety regulations. Their experience directly influences the durability and effectiveness of the repairs.

Lastly, always evaluate the environmental implications of your choices. Using Recycled Asphalt Products (RAP) can benefit both costs and sustainability. It’s a step toward responsible asphalt management.

For more in-depth information on asphalt repair techniques and factors influencing your choices, check out Asphalt Calculator USA.

Useful References for You:

- Transportation Research Board (TRB, Peer-Reviewed Research & Circulars)

- Understanding Concrete Repair Methods-ProLift Concrete Raising – ProLift Concrete Raising LLC

- ResearchGate | Find and share research

- (PDF) Factors Influencing Choice of Inguinal Hernia Repair Technique | dixon osilli – Academia.edu

- 11 Factors Affecting the Selection of Repair Materials – theconstructor.org