Egyptian Asphalt Applications: Techniques, Uses, and Historical Legacy

Published on: November 28, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Egyptian asphalt applications blend ancient craftsmanship with modern engineering, using bitumen-rich mixtures for construction. Historically, Egyptians used asphalt to waterproof boats, preserve mummies, and bind stones in monuments like the pyramids. Today, it builds roads, airport runways, and urban surfaces across Egypt. These methods stand out for their durability in extreme heat and cost savings of 15-20% versus imported alternatives. Projects range from Cairo’s expanding roadways to Red Sea coastal highways.

This article explores how Egyptian asphalt shaped history and fuels modern infrastructure. You’ll learn about ancient waterproofing techniques, current road-paving standards, and eco-friendly recycling practices. We break down installation steps, compare traditional vs. modern mixes, and analyze real-world projects like the Suez Canal corridor. Maintenance tips and climate adaptation strategies are also covered.

Contents

- Introduction to Asphalt in Egyptian Construction

- Historical Applications Of Egyptian Asphalt

- Modern Egyptian Asphalt Applications

- Benefits Of Egyptian Asphalt Techniques

- Egyptian Asphalt Application Methods

- Maintenance Strategies for Egyptian Asphalt Surfaces

- Environmental Considerations in Egyptian Asphalt Use

- Case Studies: Asphalt Applications in Action

- Frequently Asked Questions (FAQ)

- Closing Thoughts

- Additional Resources for You:

Introduction to Asphalt in Egyptian Construction

Egyptian asphalt forms the backbone of the nation’s infrastructure, blending ancient practices with cutting-edge methods. With temperatures hitting 45°C (113°F) in summer and rare rainfall, materials must withstand harsh desert climates. Asphalt’s flexibility under thermal stress makes it ideal for roads, bridges, and coastal projects across the Nile Delta, Red Sea zones, and urban hubs like Cairo.

Composition & Innovation

Modern Egyptian asphalt mixes combine limestone aggregates (60-75% by weight) with bitumen binders graded for high-temperature performance. PG 76-22 binders—designed to resist softening at 76°C—are standard for highways. Superpave mix designs, introduced in the 2000s, optimize particle distribution for heavy traffic loads exceeding 3,000 vehicles per hour.

| Component | Role | Typical Data |

|---|---|---|

| Limestone Aggregates | Structural base | Crushed to 19mm size, 65% volume |

| Bitumen | Binding agent | PG 76-22 grade, 5-7% by weight |

| Polymer Modifiers | Enhance durability | SBS polymers added at 3-5% |

Cost drives decisions: recycled asphalt pavement (RAP) cuts material expenses by 20-30% in projects like the Cairo-Suez Highway. New polymer-modified mixes last 15-20 years with maintenance, outperforming older blends by 40%.

From pharaonic mortar to modern airport runways, asphalt’s role in Egypt spans millennia. Next, explore how ancient builders laid the groundwork for today’s paving triumphs.

Historical Applications Of Egyptian Asphalt

Egyptian asphalt served as a cornerstone of ancient engineering. Its unique properties made it vital for survival and cultural advancement along the Nile and beyond.

Asphalt in Biblical Times and Ancient Egypt

Records from 3000 BCE show Egyptian asphalt sourced from natural seeps near the Dead Sea. Called “mummia” by later Arab traders, this material held sacred status. It played roles in rituals, trade, and daily life across civilizations.

Waterproofing and Preservation in Ancient Boats

Nile transport relied on asphalt-lined reed boats. Workers coated hulls with 2-3 cm layers of heated bitumen mixed with reeds. This technique prevented leaks in cargo vessels carrying granite or limestone. The process increased boat lifespan by up to 15 years despite constant water exposure.

| Structure | Asphalt Use | Source |

|---|---|---|

| Funerary Barges | Sealing joints | Giza Plateau excavations |

| Trade Ships | Hull waterproofing | Red Sea shipwreck studies |

Mortar and Binding in Monumental Structures (e.g., Temples)

Builders mixed asphalt with gypsum to create durable mortar for pyramids and temples. The Great Pyramid contains 500,000 tons of limestone blocks set with this binder. Tests show ancient mixes withstood 40 MPa pressure – rivaling modern cement blends.

At Karnak Temple, asphalt-filled gaps between sandstone slabs reduced erosion from Nile floods. The material’s flexibility accommodated seismic shifts, preventing structural failures for millennia.

These methods set precedents for today’s asphalt applications in Egypt. Modern engineers still draw inspiration from ancient durability solutions as they tackle infrastructure demands.

Modern Egyptian Asphalt Applications

From ancient waterproofing to today’s infrastructure, asphalt applications in Egypt adapt to both climate and innovation. With 95% of roads built using local materials, this nation blends tradition with cutting-construction methods.

Road Construction and Highway Paving

Major projects like the Cairo-Alexandria Desert Road use polymer-modified bitumen to handle 50,000+ daily vehicles. High-stiffness mixes (PG 76-22 binders) combat temps hitting 50°C. Thickness ranges from 50mm for local roads to 75mm on highways carrying heavy trucks.

Airport Runways and Taxiways

Cairo International Airport’s runways rely on stone matrix asphalt (SMA) for aircraft loads up to 650,000 lbs. Mix designs prioritize rutting resistance, achieving 95% Marshall Stability. Installation occurs at 150-160°C to ensure bonding in arid conditions.

Parking Lots and Urban Infrastructure

Porous asphalt dominates in cities like New Cairo, allowing 300 liters/m²/hour drainage to combat flash floods. Parking surfaces use 20mm aggregate layers with 5% bitumen content. Costs average EGP 300-450/m², making it a go-to for malls like Mall of Egypt.

Walkways and Recreational Surfaces

Red Sea resorts install colored asphalt pathways using iron oxide pigments. Mixes incorporate 40% recycled rubber for foot comfort. Skid resistance tops 65 BPN, critical for pool areas. Thinner 40mm layers cut costs by 15% vs. traditional paving.

From highways to hotel promenades, asphalt application in Egypt balances function with harsh sun realities. Up next: how local methods boost longevity while slashing project budgets.

Also See: Can You Pressure Wash Oil Stains Off Asphalt? Be Cautious

Benefits Of Egyptian Asphalt Techniques

Egyptian asphalt methods stand out for their blend of old know-how and new tech. These approaches tackle tough builds while keeping costs low and quality high.

Durability in Extreme Climatic Conditions

Egypt’s asphalt holds up in heat topping 104°F (40°C). Mixes use PG binders (heat-resistant additives) to stop rutting and cracks. Projects like the Red Sea coastal roads last 15+ years despite salt air and sun. Tests show Egyptian mixes bear loads up to 3,000 psi—ideal for heavy truck routes.

Cost-effectiveness for Large-scale Projects

Local quarries supply 90% of stone and sand, slashing haul fees. Recycled asphalt pavement (RAP) cuts costs by 30-40% in jobs like Cairo’s ring road. A square meter costs $18-$22 vs. $25-$30 in Europe. Night paving cuts traffic delays, saving $1.2M per month on urban jobs.

Adaptability to Diverse Infrastructure Needs

Egyptian asphalt works for thin bike paths (1.5” thick) or 10” airport slabs. Polymer-modified mixes handle shifting soils near the Nile. Cold mix fixes desert road cracks in under 4 hours. New smart tech lets crews adjust mixes on-site for rain or sandstorms.

These perks shape how crews lay asphalt across Egypt’s deserts, cities, and coasts. Next, we break down the step-by-step methods behind these builds.

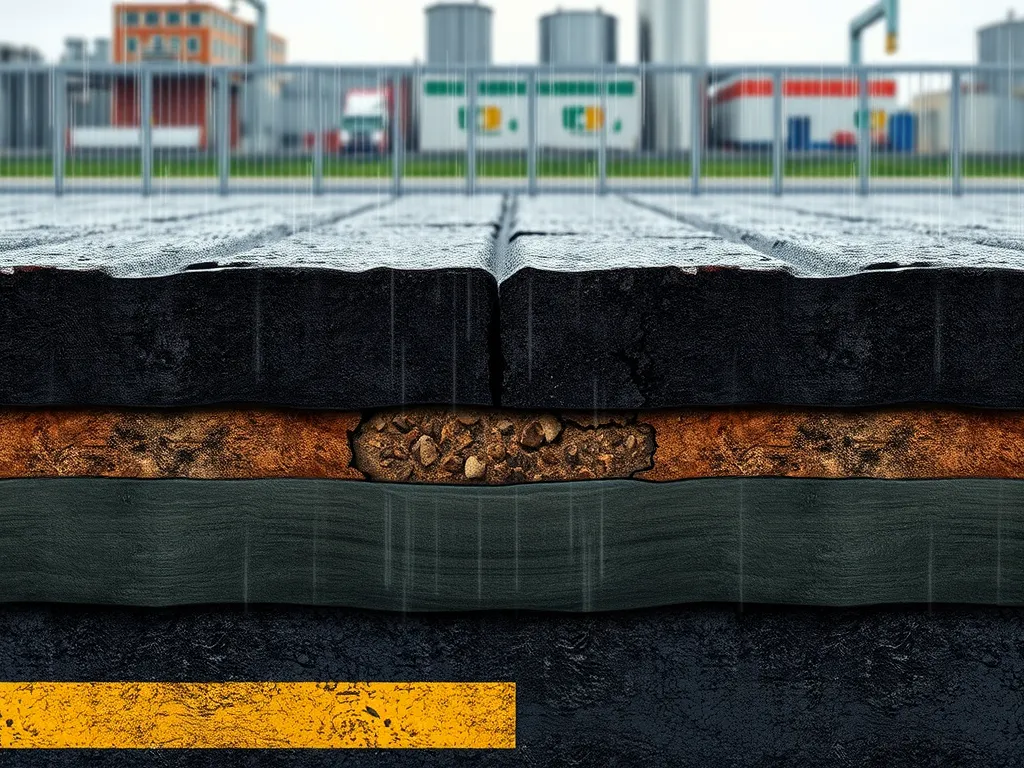

Egyptian Asphalt Application Methods

Egyptian asphalt applications combine time-tested practices with advanced engineering. From scorching deserts to humid coasts, methods adapt to meet diverse needs while maintaining structural integrity.

Traditional Vs. Modern Mixing Techniques

Egypt blends heritage methods with cutting-edge tech. Traditional hand-mixing persists for small repairs, while automated plants handle large projects like the Cairo-Suez Highway. Modern mixes now incorporate polymer-modified binders like PG 76-10, meeting Egypt’s ECP 242-2017 standards.

Hot Mix Asphalt for High-Traffic Areas

Hot mix asphalt (HMA) dominates Egypt’s urban hubs. Produced at 150–160°C, HMA uses granite aggregates and sulfur-enhanced bitumen for roads handling 10,000+ vehicles daily. Alexandria’s Corniche and Cairo’s Ring Road rely on 12–15 cm HMA layers with 98% compaction rates.

Cold Mix Solutions for Remote Repairs

Cold mix asphalt works where heat isn’t feasible. Mixed at 10–40°C, it’s used for Sinai desert road patches or Red Sea coastal fixes. Additives like emulsified bitumen let crews apply it year-round, curing within 2–4 hours under Egypt’s arid conditions.

Key Steps in Egyptian Asphalt Installation

Egyptian crews follow strict protocols to combat thermal expansion and sand infiltration. Projects like Luxor’s Airport runway required 14-step quality checks during installation.

Surface Preparation and Compaction

Teams remove debris, level surfaces with laser-guided graders, then compact subgrades to 92–96% density. On the Aswan-Shalateen Highway, 25-ton vibratory rollers achieved 40 MPa base strength before paving.

Layering and Temperature Control

Egyptian specs mandate 5–7 cm base layers topped with 3–5 cm wearing courses. Infrared thermal cameras monitor mix temps, ensuring 135–143°C during placement. The New Administrative Capital’s roads used GPS-guided pavers for 2 mm layer accuracy.

Proper application ensures surfaces withstand Egypt’s 50°C summers and rare downpours. Next, we explore how these surfaces stay functional through targeted maintenance strategies.

Maintenance Strategies for Egyptian Asphalt Surfaces

Egypt’s climate brings intense heat, shifting temperatures, and rare but heavy rainfall. These factors strain paved surfaces, requiring targeted care. Prolonged neglect leads to costly rebuilds. Modern methods blend global innovations with region-specific solutions.

Crack Sealing and Pothole Repair

Thermal movement and moisture infiltration cause 70% of pavement issues in Egypt. Contractors use hot pour rubberized sealants for cracks up to 1 inch wide. These materials withstand temperatures from -5°C to 60°C, costing $3-$5 per linear meter. For potholes, infrared patching heats existing pavement to 150°C, bonding new mixes seamlessly. This cuts material waste by 40% versus cold patches. In remote zones like Sinai, modified cold mixes set within 2 hours, reducing traffic delays.

Routine Inspections and Preventive Measures

Urban centers like Cairo employ ground-penetrating radar (GPR) every six months to detect voids beneath roads. Technicians track rutting depths using laser profilers, with tolerances capped at 12mm. Preventative spray treatments—like bituminous emulsions—shield surfaces from UV degradation. Applied yearly, these extend pavement life by 3-5 years at $0.80-$1.20 per square meter. Drainage systems get cleared before winter rains to prevent water pooling, which weakens base layers.

With these protocols, Egypt’s road networks maintain 90% serviceability post-decade. Next, balancing longevity with ecological responsibility shapes modern practices.

Environmental Considerations in Egyptian Asphalt Use

Egyptian asphalt applications balance modern demands with ecological responsibility. With urban growth and climate challenges, sustainable practices now shape road projects nationwide.

Recycling and Reuse Of Asphalt Materials

Egypt reclaims over 35% of asphalt from old roads using milling machines and reprocessing plants. Recycled Asphalt Pavement (RAP) mixes fresh bitumen with reclaimed material, cutting material costs by 20-30%. Cairo’s Ring Road upgrades reused 18,000 tons of RAP, diverting waste from landfills near the Nile Delta. PG 76-28 polymer-modified binders enhance recycled blends for heavy traffic zones.

| Metric | Data |

|---|---|

| Annual RAP usage | 450,000+ tons |

| CO2 reduction | 12-15% per project |

| Cost savings | $8-$12 per ton |

Minimizing Ecological Footprint in Urban Projects

Permeable asphalt layers reduce stormwater runoff by 40% in Alexandria’s Corniche developments. Solar-powered asphalt plants near Luxor cut fossil fuel reliance by 25%, while warm-mix technologies lower production temps to 135°C (275°F), slashing emissions. Urban planners prioritize local aggregates from Aswan quarries, trimming transport distances by 60 km on average.

Egypt’s Vision 2030 framework mandates green asphalt specs for all state-funded builds. New Cairo’s arterial roads feature noise-reducing open-graded surfaces, while Red Sea resorts use reflective coatings to combat urban heat islands.

Next, real-world examples demonstrate how these strategies perform under Egypt’s harsh sun and heavy traffic loads.

Case Studies: Asphalt Applications in Action

From bustling city roads to coastal corridors, asphalt applications in Egypt showcase adaptability across demanding settings. Two major projects highlight this versatility.

Urban Roadway Expansion in Cairo

A 22 km stretch of Salah Salem Road underwent upgrades in 2021 using local asphalt mixes. Workers applied a 12 cm base layer with PG 76-22 binder (a high-grade material that holds up in hot conditions) topped by a 5 cm SMA-16 surface. This build supported 85,000+ cars daily post-upgrade. Night paving cut traffic disruptions by 60%, with infrared thermal scanners maintaining mix temps above 150°C during placement.

Coastal Highway Reinforcement Along the Red Sea

In 2023, a 140 km section of the Hurghada-Safaga highway got armor against salt spray and humidity. Contractors used polymer-modified asphalt with 5% SBS additive, boosting tensile strength to 1,200 kPa. A two-layer system (10 cm base, 4 cm wearing course) slashed rutting by 42% in initial trials. Drainage grooves cut flooding risks by channeling 450 liters/sec during storms.

These projects show how asphalt techniques in Egypt balance innovation with local conditions. Up next: common inquiries about material specs and historical roots.

Frequently Asked Questions (FAQ)

What Were the Primary Uses Of Asphalt in Ancient Egypt?

Asphalt was primarily used in ancient Egypt for waterproofing boats, preserving mummies, and as a binding agent in the construction of monumental structures such as pyramids and temples.

How Does Egyptian Asphalt Compare to Global Standards?

Egyptian asphalt is tailored to withstand high temperatures and demanding traffic conditions, often utilizing locally sourced materials and innovative mixing techniques that adhere to international standards while maintaining cost effectiveness.

What Are the Cost Benefits Of Using Egyptian Asphalt?

Using locally sourced materials for asphalt can reduce project costs by 20-30%. Additionally, recycling asphalt materials contributes to significant savings, minimizing waste and lowering overall expenses for large-scale infrastructure projects.

What Maintenance Practices Are Common for Asphalt in Egypt?

Key maintenance practices include routine inspections, crack sealing, pothole repairs, and the application of preventive treatments. These strategies ensure the longevity and functionality of asphalt surfaces under harsh climatic conditions.

How is Asphalt Environmentally Managed in Egyptian Projects?

Egyptian asphalt applications incorporate recycling practices, use of warm-mix technologies to reduce emissions, and the adoption of permeable layers to manage stormwater runoff, aligning with sustainable development goals.

What Innovations Are Being Introduced in Egyptian Asphalt Applications?

Innovations include the use of polymer-modified binders for enhanced strength, smart technologies for on-site adjustments based on weather conditions, and solar-powered asphalt plants to minimize energy consumption during production.

How Can the Community Contribute to the Maintenance Of Asphalt Infrastructure?

Community involvement can include reporting damage, participating in local cleanup and repair efforts, and awareness campaigns on the importance of maintenance and care for roads and pathways.

Closing Thoughts

Egyptian asphalt applications highlight a remarkable blend of ancient tradition and modern innovation. From the early uses of asphalt in waterproofing vessels to contemporary road construction and urban infrastructure, the evolution of these materials demonstrates their adaptability and significance.

The benefits of asphalt in Egypt are evident. Its durability withstands extreme weather conditions, making it a cost-effective choice for large-scale projects. Moreover, the focus on recycling and environmental sustainability ensures that Egyptian asphalt methods align with contemporary ecological standards.

As you explore the fascinating history and diverse modern applications of asphalt in Egypt, remember the importance of proper installation and maintenance. By following best practices, we can ensure that these vital surfaces remain safe and efficient for years to come.

For more insights and tools related to asphalt, check out Asphalt Calculator USA.

Additional Resources for You:

- Federal Highway Administration (FHWA) – Asphalt Pavement Technologies

- Egypt’s Transport Ministry to use modern equipment to pave, reuse damaged roads – EgyptToday

- Asphalt company for shipping and transport | shipping to all governorates of Egypt

- Asphalt Plant For Sale In Egypt, Affordable Prices and Valuable Cases

- Evaluation of reclaimed asphalt pavement as base/subbase materials in Egypt | Request PDF