Efficient Repair Methods to Extend Asphalt Life: Save Money & Reduce Headaches

Published on: November 29, 2025 | Last Updated: April 14, 2025

Written By: George Voss

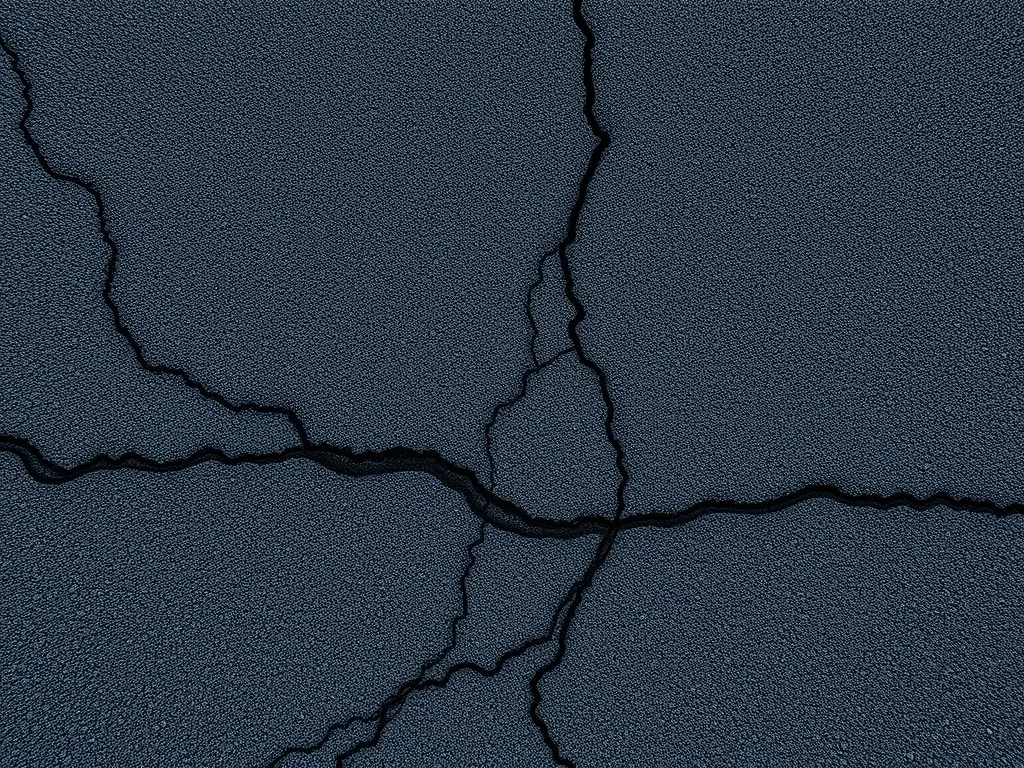

Efficient repair methods to extend asphalt life use targeted fixes that stop pavement damage early, preventing small issues from becoming costly replacements. These techniques differ from standard repairs by focusing on material longevity and cost-per-square-foot savings. Crack sealing blocks water intrusion. Infrared patching bonds seamlessly with existing pavement. Thin overlays add 8-12 years of service life at half the cost of full reconstruction. Properly applied methods can delay full repaving by 15+ years.

This guide breaks down the top asphalt preservation strategies used by DOT engineers and commercial contractors. Learn when to use rubberized crack fillers versus cold-pour sealants. Compare throw-and-roll pothole fixes to infrared thermal repairs. Discover how sealcoat frequency impacts surface oxidation rates. We’ll cover drainage tweaks that prevent base failures and eco-friendly options like recycled asphalt pavement (RAP) mixes containing 20-40% reused materials.

Contents

Why Asphalt Longevity Matters

Maintaining pavement integrity directly affects safety, operational budgets, and environmental impact. Every dollar spent on preserving existing asphalt prevents spending $6-$10 on full reconstruction later. Let’s break down how strategic care pays dividends.

Cost Savings Through Preventative Maintenance

Proactive asphalt maintenance techniques slash long-term expenses. Sealcoating applied every 2-3 years at $0.15-$0.25 per square foot blocks oxidation and water penetration. Compare that to reconstruction costs averaging $3-$7 per square foot. Regular crack filling extends pavement life 5-7 years before needing overlays.

| Maintenance Action | Cost Range | Lifespan Added |

|---|---|---|

| Crack Sealing | $0.50-$2.50/lin ft | 3-5 years |

| Pothole Patching | $25-$100 per hole | 2-4 years |

| 2″ Overlay | $1.50-$3.00/sq ft | 8-12 years |

Impact Of Timely Repairs on Lifespan

Unaddressed cracks wider than ¼ inch let 300% more water infiltrate base layers annually. Infrared asphalt patching restores 95% of original strength versus 70% with cold patches. Pavements receiving annual inspections last 25+ years – 40% longer than neglected surfaces. The Federal Highway Administration notes proper drainage maintenance alone adds 7-10 years to asphalt lifespan.

Next, we’ll analyze specific repair techniques for maximum pavement preservation. From filler materials to advanced thermal processes, each method targets distinct deterioration patterns.

Key Asphalt Repair Techniques to Extend Lifespan

Proper asphalt maintenance techniques target specific damage types at optimal stages. Selecting the right repair method can add 5-15 years to pavement service life while cutting long-term costs by 30-50%.

Crack Filling and Sealing

Unsealed cracks allow water penetration that erodes base materials. Repair within 6 months of formation prevents accelerated deterioration.

Hot-Pour Rubberized Crack Filler

Heated to 375°F, this flexible sealant bonds tightly to crack walls. Used for cracks wider than ¼ inch, it expands/contracts with temperature shifts. Lasts 3-5 years at $0.30-$0.50 per linear foot.

Cold-Applied Asphalt Sealants

Ready-to-use emulsion blends work for cracks under ¼ inch. Apply at temperatures above 50°F using pour pots or spray systems. Sets within 2 hours at $0.15-$0.25 per linear foot.

Pothole Repair Methods

Potholes form when water weakens subbase layers under traffic loads. Permanent repairs require full-depth restoration.

Throw-and-Roll Cold Patch

Emergency fix using polymer-modified asphalt mixes. Compact with truck tires for temporary repairs lasting 6-12 months. Costs $25-$40 per pothole but requires frequent rework.

Infrared Asphalt Patching

Heats existing pavement to 300°F, blending new/recycled asphalt seamlessly. Eliminates cold joints that fail prematurely. Lasts 5-8 years at $100-$150 per repair area.

Surface Restoration Strategies

When cracks cover over 25% of the surface, localized repairs become less cost-effective than full treatments.

Asphalt Overlay Installation

Adds 1.5-3 inch layer of fresh asphalt over prepared base. Extends life 8-12 years when applied before structural failures occur. Costs $2.50-$4.00 per square foot.

Spray Injection Repair

High-pressure application fills voids with aggregate/emulsion mix. Bonds tightly to existing pavement edges. Works for alligator cracks and small sinkholes at $3-$7 per square foot.

These asphalt repair solutions form the foundation of pavement preservation – but true longevity requires combining them with proactive care. Next, we’ll explore scheduled maintenance routines that boost performance between major repairs.

Preventative Maintenance for Asphalt Longevity

Proactive care reduces costly interventions while boosting pavement performance. Focused strategies like sealcoating and drainage management protect structural integrity against weather, traffic, and time.

Sealcoating Best Practices

This protective layer blocks UV rays, resists fuel spills, and prevents water infiltration. Proper application requires attention to timing and material selection.

Optimal Application Frequency

New pavements need initial sealcoating after 12 months. Reapply every 3-5 years based on traffic volume and climate conditions. High-use lots or areas with freeze-thaw cycles benefit from 24-month cycles. Use infrared thermometers to verify surface temps stay between 50°F-85°F during application.

Coal Tar vs. Asphalt-Based Sealers

| Factor | Coal Tar | Asphalt-Based |

|---|---|---|

| Durability | 7-10 years | 5-8 years |

| Cost/Sq Ft | $0.18-$0.30 | $0.15-$0.25 |

| Environmental Impact | High PAHs | Low VOCs |

Coal tar contains polycyclic aromatic hydrocarbons (PAHs) linked to ecological concerns. Asphalt emulsions meet modern EPA guidelines, using polymer-modified blends for enhanced flexibility.

Drainage System Maintenance

Water infiltration causes 80% of pavement failures. Keep runoff systems functioning through routine inspections and corrections.

Cleaning Catch Basins

Remove sediment buildup quarterly using vacuum trucks or shoveling. Clogged basins create standing water that penetrates subbase layers. Install filter fabric inserts to trap debris while allowing water flow.

Regrading Edge Drains

Verify drainage slopes maintain 2% minimum grade. Use laser levels to check for settled areas near pavement edges. Restore proper pitch with compacted fill material, ensuring water moves 6-10 feet away from pavement within 24 hours of rainfall.

These maintenance protocols set the stage for exploring eco-friendly innovations in pavement preservation.

Also See: Best Practices for Site Grading Before Asphalt Installation

Environmental Considerations in Asphalt Repair

Modern asphalt repair methods balance durability with ecological responsibility. Sustainable practices reduce environmental harm while maintaining pavement performance.

Recycled Asphalt Applications

Reclaimed Asphalt Pavement (RAP) reuse cuts material costs by 30-40% and reduces CO2 emissions by 20% per ton. Cold recycling techniques blend milled asphalt with emulsion binders at ambient temperatures, saving 35% energy compared to hot-mix production. States like California and Texas now mandate 15-25% RAP in highway projects.

| Material | Cost/Ton | CO2 Emissions (kg/ton) |

|---|---|---|

| Virgin Asphalt | $75 | 31 |

| 50% RAP Mix | $48 | 19 |

Low-voc Repair Materials

New water-based sealants emit 60% fewer volatile organic compounds than traditional solvent-based products. Bio-modified binders from soybean or pine resin derivatives reduce petroleum use by 15-20% in crack fillers. EPA-compliant patching compounds meet ASTM D6626 standards while maintaining 300-400% elongation capacity.

| Product Type | VOC Content (g/L) | Cure Time |

|---|---|---|

| Traditional Sealant | 450 | 6 hours |

| Low-VOC Formula | 150 | 4.5 hours |

These eco-friendly approaches complement technical repairs. For common implementation challenges, professionals turn to targeted solutions.

Frequently Asked Questions

How Can I Make My Asphalt Last Longer?

To extend the life of your asphalt, implement regular maintenance practices such as crack filling, sealcoating, and timely pothole repairs. Ensure proper drainage systems are operational to prevent water damage and consider scheduling inspections annually to catch potential issues early.

What Are the Most Effective Asphalt Repair Methods?

Some of the most effective methods include hot-pour rubberized crack filling, infrared asphalt patching, and asphalt overlay installations. Each technique targets specific types of damage and can significantly prolong the life of your pavement.

Can New Asphalt Be Applied Over Old Pavement?

Yes, new asphalt can be applied over old pavement, particularly if the existing layer is stable and has no severe deformation or structural issues. Proper surface preparation is crucial to ensure adequate bonding and performance.

What’s the Best Patching Technique for Asphalt?

The best patching technique depends on the specific issue. For larger potholes and surface defects, infrared asphalt patching is highly effective as it integrates new and existing asphalt seamlessly. For small cracks, hot-pour rubberized fillers provide durable and flexible sealing.

Closing Thoughts

Extending the life of asphalt requires a proactive approach. By employing efficient repair methods like crack filling, pothole repairs, and surface restoration, property owners can significantly enhance the durability of their pavements. Preventative maintenance, including regular sealcoating and effective drainage management, plays a pivotal role in prolonging asphalt longevity.

Moreover, considering environmentally friendly options such as recycled materials and low-VOC products not only benefits your asphalt surfaces but also contributes to sustainable practices in construction.

For more detailed insights and tools to maximize your asphalt’s lifespan, be sure to visit Asphalt Calculator USA.