Effective Sealing Products for Asphalt Driveways

Published on: November 25, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Effective sealing products for asphalt driveways are protective coatings made from coal tar, asphalt emulsion, acrylic polymers, or fast-drying liquids. These sealants block UV rays, prevent water damage, and resist oil stains while restoring the driveway’s dark finish. Key differences include durability (1-5 years), material costs ($0.15-$0.25 per square foot), and environmental safety – coal tar lasts longest but contains pollutants. Homeowners prioritize climate needs, crack severity, and budget when selecting sealers for maximum longevity.

This guide breaks down four sealer types with performance data, including drying times (2-48 hours) and coverage rates (50-150 sqft/gal). Compare eco-friendly options like low-VOC water-based formulas and biodegradable additives. Learn professional application methods, crack repair steps, and maintenance schedules. Get insights on top brands like SealMaster and GemSeal, plus answers to curing timelines and spray-versus-roll debates.

Contents

- Why Sealing Your Asphalt Driveway Matters

- Types Of Asphalt Driveway Sealers

- How to Choose the Best Sealant for Your Asphalt Driveway

- Application Methods for Asphalt Driveway Sealants

- Maintaining a Sealed Asphalt Driveway

- Eco-friendly Asphalt Sealing Options

- FAQs: Asphalt Driveway Sealing Products

- Closing Thoughts

- Additional Resources for You:

Why Sealing Your Asphalt Driveway Matters

Unsealed driveways face relentless stress from traffic, weather, nd time. Quality sealing products shield surfaces while preserving structural integrity. Let’s break down the core benefits.

Protection Against Weather and Wear

Bitumen—the binding agent in asphalt—degrades when exposed to UV rays, water, nd freeze-thaw cycles. Effective asphalt driveway sealer forms protective layer blocking oxidation. Tests show sealed surfaces resist cracking 60% better than untreated ones in temperatures ranging from -20°F to 120°F. Water intrusion, major cause of potholes, gets stopped by robust seal coating mixture filling micro-cracks up to 1/8 inch wide.

Enhancing Curb Appeal and Longevity

Fresh sealant restores the deep black finish of new asphalt, boosting property value by up to 5%. Polymer-modified asphalt sealants for driveways maintain flexibility, preventing brittle surfaces under heavy vehicles. Driveways sealed every 2-3 years last 50% longer than unsealed ones— 15-year lifespan versus 10 years. Premium products like coal tar-based blends or acrylics offer UV-blocking pigments, keeping your surface jet-black despite sun exposure.

Ready to explore specific sealing solutions? Let’s examine the pros, cons, nd best uses for each type of driveway sealant.

Types Of Asphalt Driveway Sealers

Selecting the right asphalt driveway sealant depends on performance needs, environmental factors, and surface conditions. Four primary options dominate the market, each with unique strengths and limitations.

Coal Tar-based Sealants

Coal tar sealant, a petroleum byproduct, has been used for decades to protect asphalt surfaces. Containing 35-45% coal tar pitch, these products form a thick, glossy barrier against harsh elements.

Benefits of Coal Tar Sealant for Asphalt

This asphalt sealant for blacktop resists oil leaks, gasoline spills, and de-icing salts better than other options. With a 5-7 year lifespan, coal tar provides long-term protection against cracks and oxidation. The deep black finish restores curb appeal effectively.

Drawbacks of Coal Tar Driveway Sealer

Polycyclic aromatic hydrocarbons (PAHs) in coal tar pose environmental risks, leading to bans in 12 U.S. states. The strong odor lingers for 48+ hours after application. At $25-$35 per 5-gallon pail, costs run 15% higher than emulsion alternatives.

Asphalt Emulsion Sealers

Water-based asphalt emulsion sealers mix liquid asphalt with clay fillers and polymers. These driveway sealing products contain 55-65% solids, making them popular for DIY projects.

Benefits of Asphalt Emulsion Sealant

Low-VOC formulas meet eco-friendly standards in most regions. The sealer bonds well with existing asphalt driveway surfaces, filling hairline cracks up to 1/8″. Dries to touch within 4-6 hours under 70°F conditions. Costs average $18-$28 per pail.

Drawbacks of Asphalt Emulsion Sealer

Less resistant to automotive fluids compared to coal tar. Requires reapplication every 2-3 years. May show streaking if applied during high humidity or temperatures below 50°F.

Acrylic Sealers for Asphalt

Polymer-based acrylic sealants offer advanced protection through flexible resin formulas. Often used with fiber additives for crack bridging up to 1/4″.

Benefits of Acrylic Asphalt Sealant

UV-resistant compounds prevent fading better than traditional sealers. The semi-gloss finish enhances color without the jet-black look of coal tar. Performs well in temperature extremes (-30°F to 120°F). Lasts 4-5 years with proper application.

Drawbacks of Acrylic Driveway Sealer

Higher upfront cost at $40-$60 per gallon. Requires precise mixing ratios for optimal performance. Not recommended for surfaces with existing oil stains unless pre-treated.

Fast-drying Liquid Asphalt Sealers

These solvent-based formulas combine asphalt cement with rapid carriers for quick curing. Cure times range from 30 minutes to 2 hours, depending on weather.

Ideal Use Cases for Liquid Sealant

Best for spot repairs or small driveways needing same-day use. Effective for sealing blacktop driveway edges and around drains. Commercial contractors favor spray systems for large parking areas needing fast turnaround.

With these options in mind, the next step involves matching sealer types to your specific climate, budget, and driveway condition.

How to Choose the Best Sealant for Your Asphalt Driveway

Selecting the right asphalt driveway sealer requires balancing performance, budget, and local conditions. Three factors dictate success: climate resilience, surface repairs, and long-term value.

Climate Considerations

Temperature swings and precipitation patterns steer sealant choices. Use coal tar-based driveway sealing products in regions with frequent freeze-thaw cycles – their flexible polymers resist cracking at -20°F. In areas with intense sun exposure (UV index above 8), acrylic asphalt sealants last 3-5 years versus 1-2 years for standard emulsions. High-humidity zones demand fast-drying liquid sealants with 30-minute cure times to prevent washouts.

Surface Condition and Crack Severity

Inspect your driveway’s surface before buying seal asphalt driveway mix. For hairline cracks under 1/4”, use rubberized fillers blended into the sealant. Larger fissures (over 1/2”) require patching with asphalt repair compounds first. Severely weathered surfaces benefit from thick, fiber-reinforced sealants applied at 0.15 gallons per square yard. Always clean oil stains with trisodium phosphate (TSP) solutions to ensure adhesion.

Cost Vs. Durability Comparison

- Budget pick: Asphalt emulsion sealers ($0.12-$0.18 per sq.ft) last 1-2 years

- Mid-range: Polymer-modified coal tar ($0.20-$0.28 per sq.ft) lasts 3-4 years

- Premium: High-solids acrylic ($0.35-$0.45 per sq.ft) lasts 5-7 years

Labor costs add $0.30-$0.50 per sq.ft for professional seal coating driveway services.

Once you’ve selected your sealant, proper application techniques maximize its protective power. Let’s break down the most efficient methods…

Also See: Comparison Of Paver Types for Different Projects

Application Methods for Asphalt Driveway Sealants

Selecting the right technique boosts performance of your chosen asphalt driveway sealer. Two primary methods dominate residential projects: spray-on systems versus traditional roll-on applications. Each impacts finish quality, labor needs, and long-term protection.

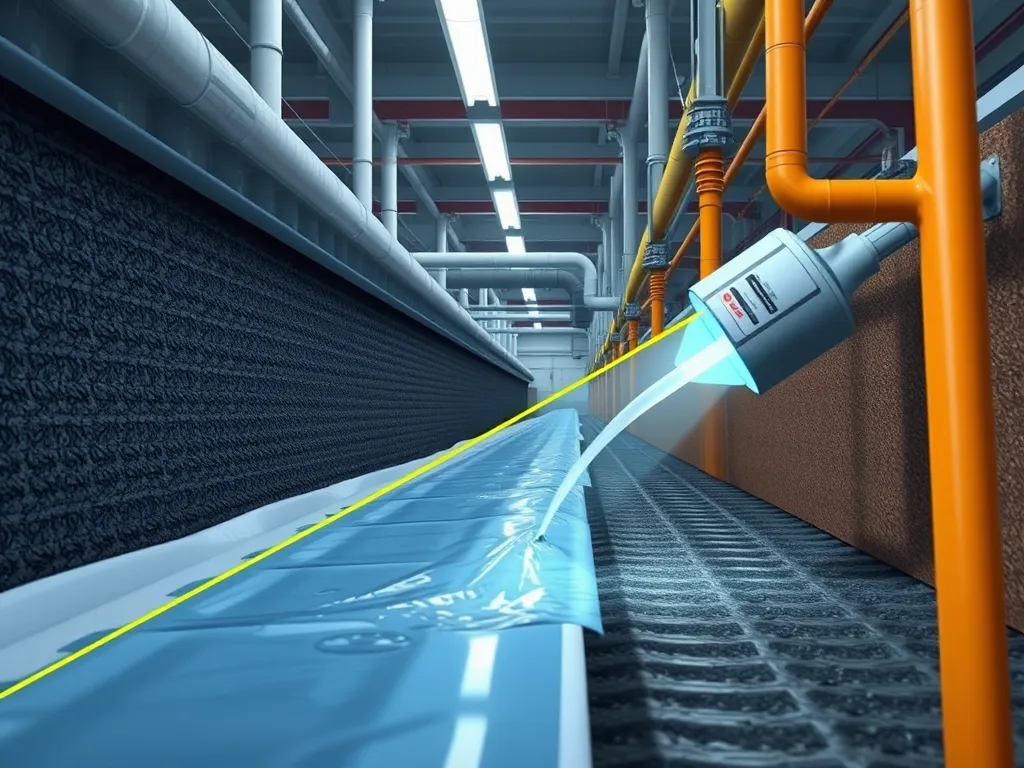

Spray-on Vs. Roll-on Sealant Application

Spray equipment distributes liquid driveway sealant rapidly, while rollers provide precise control. Your decision hinges on surface size, budget, and desired texture.

Pros and Cons of Spraying Asphalt Sealer

Sprayers cover 500-800 sq ft per hour, ideal for large driveways. They create uniform coats but demand specialized pumps costing $200-$500. Overspray risks staining adjacent surfaces. Most fast-drying liquid asphalt sealers work best with spray systems due to their thin consistency.

Pros and Cons of Rolling Asphalt Sealer

Rollers (6-18 inch widths) suit DIYers, requiring $30-$80 tools. They push seal asphalt driveway mix into cracks better but leave streak marks if unevenly applied. Thicker asphalt sealants for driveways perform well with rollers, needing 2-3 gallons per 100 sq ft.

Step-by-step Sealing Process

Proper execution extends the life of driveway sealing products by 3-5 years. Follow manufacturer specs for mixing ratios, coverage rates, and drying conditions.

Preparing the Asphalt Surface

Clear debris with stiff brooms or leaf blowers. Repair cracks wider than 1/8 inch using rubberized filler. Power wash surfaces; let dry 24-48 hours. Oil stains require degreasers to prevent seal coating mixture adhesion failure.

Mixing and Applying the Sealant

Stir seal driveway mix thoroughly—never dilute unless specified. Pour into spray tanks or roller trays. Maintain wet edges during application. Overlap passes by 4-6 inches to prevent gaps. Two thin coats outperform single thick layers.

Curing Time for Asphalt Sealcoat

Most products need 24-48 hours before foot traffic. Full cure (7 days) is needed before vehicle use. Temperatures below 50°F or rain within 4-6 hours can ruin fresh blacktop sealant. Use caution tape or cones to block access.

With your driveway sealed, focus shifts to preserving that sleek finish. Proper maintenance routines ensure your investment withstands seasons of use.

Maintaining a Sealed Asphalt Driveway

A solid maintenance plan keeps your asphalt driveway functional and visually sharp. Focus on timing and surface prep to maximize results from your asphalt driveway sealer.

Optimal Re-sealing Frequency

Most asphalt driveways need fresh sealant every 2-3 years. Harsh sun, snow, or heavy traffic might push this to 1-2 years. Check for fading color or rough texture—both signal it’s time to act. Coal tar-based driveway sealant lasts up to 4 years in mild climates, while acrylic options often require annual touch-ups.

Repairing Cracks Before Sealing

Fix cracks 24 hours prior to applying asphalt sealants for driveways. Use a rubberized crack filler for gaps under ½” or cold-pour mixtures for larger voids. Clean debris with a wire brush or blower. Ignoring this step lets moisture slip through, ruining your seal asphalt driveway mix. For cracks wider than ¼”, apply patching compound and let it dry fully.

Proper maintenance sets the stage for exploring options that align with both durability goals and planetary impact.

Eco-friendly Asphalt Sealing Options

Environmentally conscious homeowners now access advanced sealing solutions balancing performance with reduced ecological impact. These products minimize chemical runoff while maintaining durability against UV rays, freeze-thaw cycles, and vehicle traffic.

Low-voc Water-based Sealers

Water-based formulas with under 100 grams per liter of volatile organic compounds (VOCs) dominate green sealing markets. Brands like GreenSeal Pro and EcoCoat DriveGuard cut airborne emissions by 60-80% compared to traditional solvent-based products. These asphalt driveway sealers use acrylic polymers or refined coal tar alternatives, delivering 2-4 years of protection at $0.15-$0.25 per square foot. Apply them via spray systems or squeegee at 55°F minimum for proper curing within 12-24 hours.

Biodegradable Sealant Additives

Bio-based enhancers like SoySeal Boost integrate with standard asphalt sealant for driveways to accelerate breakdown in soil without compromising durability. Mixed at 5-8% concentration, these plant-derived additives improve flexibility by 20% in temperature swings from -20°F to 120°F. Tests show 90% biodegradation within 18 months versus 30+ years for conventional formulas. Expect 10-15% higher upfront costs balanced by reduced environmental fees and eligibility for local green rebates.

Proper product selection sets the stage for addressing common sealing challenges – let’s examine frequent questions about application techniques and performance benchmarks.

FAQs: Asphalt Driveway Sealing Products

What Do Professionals Use to Seal Asphalt Driveways?

Professionals often opt for high-quality coal tar-based or polymer-modified asphalt sealers due to their durability and long-lasting protection. They may also choose eco-friendly options, such as low-VOC water-based sealers, depending on local regulations and client preferences.

Is Spraying or Rolling More Effective for Asphalt Sealer?

Both methods have their advantages. Spraying offers faster coverage and uniform application over large areas, while rolling allows for better control in application and is often favored for DIY projects. The choice depends on the specific needs of the driveway and the user’s experience.

Which Sealant Works Best for Cracked Asphalt Driveways?

For cracked asphalt driveways, coal tar-based sealants or high-strength acrylics are recommended, as they have superior crack-filling capabilities and flexibility. It’s important to address larger cracks with patching materials before sealing for optimal results.

How Long Does Asphalt Sealant Take to Cure?

The curing time for asphalt sealant can vary; typically, sealants need 24-48 hours before foot traffic and up to 7 days before vehicles can be driven on the surface. Factors like temperature and humidity can affect these times significantly.

Where Can I Find Reliable Asphalt Sealer Reviews?

Reliable reviews for asphalt sealers can be found on home improvement websites, consumer review platforms, or in professional publications focused on building materials. Additionally, checking feedback on retailer sites can provide insights from users who have firsthand experience.

Closing Thoughts

Sealing your asphalt driveway is not just a cosmetic decision; it plays a crucial role in protecting your investment. The right sealing product enhances durability, defends against harsh weather, and improves the overall appearance of your property.

With various options available, from coal tar-based sealants to eco-friendly solutions, choosing the best one requires careful consideration of your driveway’s specific needs. Remember to factor in local climate, surface condition, and desired longevity. Proper application methods and regular maintenance will further extend the life of your driveway.

For more detailed information on effective sealing products and best practices, check out Asphalt Calculator USA. Your asphalt deserves the best care possible!