Asphalt Grading Systems: Your Guide to Stronger, Smarter Roads

Published on: November 15, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Different grading systems for asphalt categorize materials by their stiffness, temperature tolerance, and durability under stress. These systems—Performance Grading (PG), viscosity, penetration, and ductility—help engineers pick the right asphalt for specific climates and traffic loads. For example, PG 64-22 asphalt works in regions with winter lows of -22°F, while PG 70-10 handles summer highs up to 115°F. Choosing the correct grade prevents cracks, rutting, and costly repairs.

This article explains how each grading method works and where it excels. You’ll see why Minnesota uses PG 58-34 for icy highways, while Arizona opts for PG 76-16. We’ll compare lab tests like the bending beam rheometer (measures cold-weather flexibility) and dynamic shear rheometer (tests heat resistance). By the end, you’ll know how to match grades to project needs—whether paving a driveway or a 10,000-vehicle-per-day interstate.

Contents

- What Are the Different Grades Of Asphalt?

- Methods Of Grading Asphalt Systems

- Performance Grading (PG) System Explained

- Viscosity and Temperature in Asphalt Grading

- Specifications for Performance-graded Asphalt Binders

- Suitable Asphalt Grades for Road Construction

- Environmental Considerations in Asphalt Grading

- FAQs: Asphalt Grading Systems

- Closing Thoughts

- Useful References for You:

What Are the Different Grades Of Asphalt?

Asphalt grades group materials by physical traits and climate suitability. Four main grading systems dominate: Performance Grading (PG), Viscosity, Penetration, and Ductility. Each targets distinct asphalt behaviors, from flow resistance to cold flexibility.

Overview Of Asphalt Grade Classifications

Performance Grading (PG), part of the Superpave system, ranks asphalt by its working temp span. A PG 64-22 grade functions in pavements from -22°C to 64°C. Viscosity grading (AC-10, AC-20) tracks asphalt’s flow at 60°C. Penetration grades (60/70, 85/100) apply a needle test to quantify hardness at 25°C. Ductility grading measures stretch capacity before breaking, vital for cold zones.

Key Differences Between Asphalt Grades

PG systems focus on climate-specific performance using advanced tools like dynamic shear rheometers. Viscosity grades prioritize high-temp stability, with AC-20 handling heavy trucks better than AC-10. Penetration grades lack temp range data but cost 15-20% less for basic projects. Ductility requirements vary by region—northern states often demand 100+ cm stretch to avoid thermal cracks. Mix designs using PG binders typically last 50% longer than penetration-grade pavements in freeze-thaw cycles.

Grading systems for asphalt adapt to project needs. Next, we’ll break down how each method works in practice.

Methods Of Grading Asphalt Systems

Four main frameworks classify asphalt binders based on physical traits and climatic fit. Each system informs how pavements hold up under traffic loads, shifting temps, and aging.

Viscosity-based Grading

This method ranks asphalt by flow resistance at 60°C (140°F). A rotational viscometer gauges how thick or thin a binder acts during mixing and compaction. Common grades include AC-10 (thin) for cool zones and AC-20 (thick) for hot regions. High-viscosity asphalt works in areas with annual air temps surpassing 27°C (80°F).

| Grade | Viscosity Range (Poises) | Typical Use |

|---|---|---|

| AC-5 | 500-1000 | Spray applications |

| AC-10 | 1000-2000 | Cold climates |

| AC-20 | 2000-4000 | Moderate to warm zones |

Performance Grading (PG System)

Introduced in 1993 with Superpave technology, PG binders link to actual pavement temps. A PG 64-22 grade withstands highs of 64°C (147°F) and lows of -22°C (-8°F). Labs simulate aging via rolling thin-film ovens and pressure aging vessels. This system accounts for traffic speed, with stiffer binders (PG 76-XX) for slow-moving trucks.

Penetration Grading

This old-school approach uses a needle to sink into asphalt samples at 25°C (77°F) for 5 seconds. Depth (in 0.1 mm units) decides grades: 60-70 pen for hot climates, 85-100 for cold. Though simple, it fails to factor in thermal cracking or long-term aging.

Ductility Grading

Ductility tests show a binder’s capacity to stretch without snapping. A sample pulls apart at 25°C (77°F) until it breaks; length (in cm) dictates grading. High ductility (>100 cm) means strong crack resistance. This trait matters most in frost-prone areas with frequent freeze-thaw cycles.

Choosing a grading asphalt system impacts pavement lifespan, maintenance costs, and load capacity. Up next: a deep look at how PG binders match specific roads and climates.

Performance Grading (PG) System Explained

The Performance Grading (PG) system revolutionized asphalt specifications by linking binder performance to real-world conditions. Developed under the Strategic Highway Research Program (SHRP), this method evaluates asphalt based on climate and traffic demands.

What is Performance-graded Asphalt?

Performance-graded asphalt refers to binders tested under simulated weather and loading conditions. PG grades like PG 64-22 or PG 70-10 indicate the asphalt’s usable temperature range. The first number (64°C) shows the maximum pavement temperature the binder can withstand without rutting. The second number (-22°C) represents the lowest temperature before thermal cracking occurs. This system replaced older methods by focusing on rheology—how asphalt deforms under stress.

How to Determine the PG Grade Of Asphalt

Engineers test asphalt binders using the Dynamic Shear Rheometer (DSR) and Bending Beam Rheometer (BBR). The DSR measures resistance to deformation at high temperatures, while the BBR assesses flexibility in freezing conditions. Tests follow AASHTO M320 standards, with results cross-referenced against regional climate data. For example, Phoenix roads require higher high-temperature grades (PG 76-xx) than Minnesota pavements (PG 58-xx).

Applications Of PG 64-22 Asphalt

PG 64-22 works best in regions with moderate climates, where pavement temperatures stay between 46°F and 100°F. Used across the Midwest and Mid-Atlantic states, this grade handles interstate highways and suburban roads. Its balanced viscosity prevents rutting under summer traffic while resisting cracks during mild winters. Contractors often choose PG 64-22 for overlays due to its cost-efficiency—$3-$5 per square yard installed.

Applications Of PG 70-10 Asphalt

PG 70-10 excels in cold climates with extreme temperature swings, like Montana or North Dakota. The “-10” rating allows use down to -10°F, making it ideal for bridge decks and high-altitude roads. This grade’s polymer-modified structure resists thermal cracking better than standard binders. State DOTs frequently specify PG 70-10 for intersections and truck lanes, where stopping forces increase shear stress by 40-60%.

These PG grades show how modern asphalt systems balance climate resilience with structural demands. Next, we’ll examine how viscosity and temperature charts guide grade selection for specific projects.

Also See: Benefits Of Using Artificial Aggregates in Asphalt

Viscosity and Temperature in Asphalt Grading

Asphalt behaves differently under heat or cold. These changes directly shape how engineers select grades for roads. Two key factors drive decisions: viscosity shifts with temperature and data from viscosity-temperature charts.

Viscosity Of Asphalt at Different Temperatures

Viscosity measures asphalt’s thickness at specific temperatures. At 140°F (60°C), VG-30 grade asphalt maintains 3,000 Poise – thick enough to resist rutting under heavy traffic. At 275°F (135°C), the same asphalt flows freely for smooth pavement application. Systems like viscosity grading (VG) classify binders based on these flow properties.

Three factors tie viscosity to grading:

- Workability: Lower viscosity at high temps aids mixing and laying

- Rutting resistance: Higher viscosity at service temps prevents deformation

- Cracking resistance: Proper viscosity at low temps avoids brittle fractures

Significance Of the Asphalt Viscosity-temperature Chart

This chart plots viscosity against temperature for all asphalt grades. Contractors use it to:

- Match binder grades to regional climate zones

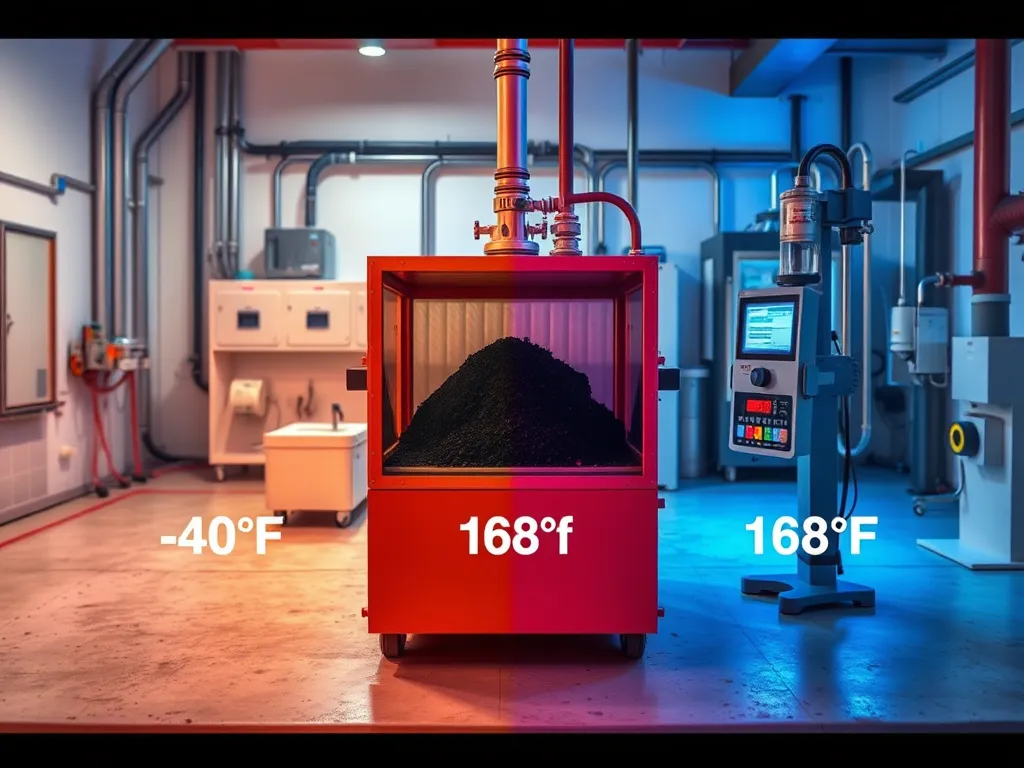

- Predict pavement performance from -40°F to 158°F (-40°C to 70°C)

- Verify compliance with Superpave mix designs

For example, PG 64-22 asphalt shows optimal viscosity between 50°F and 85°F (10°C-29°C), making it suitable for moderate climates. The chart also guides recycling by showing how aged binders blend with new materials.

With viscosity-temperature relationships clarified, next examine how these principles translate into formal binder specifications.

Specifications for Performance-graded Asphalt Binders

Performance-graded (PG) asphalt binders follow strict rules to match climatic and traffic conditions. This part of asphalt grading systems links lab results to real-world road actions. Binding agents must pass physical property checks at both high and low temps.

Key Standards and Requirements

PG binders follow AASHTO M 320 and ASTM D6373 rules. These docs list limits for rutting, cracking, and aging. High-temp grades span from PG 52 up to PG 82, low-temp from PG -10 down to PG -34. A PG 64-22 mix must handle 64°C heat without rutting and -22°C cold without cracking. Binder stiffness stays under 300 MPa in cold checks using bending beam rheometer tests.

Testing Protocols for Compliance

Dynamic shear rheometer (DSR) tests confirm rutting resistance at high temps. Rolling thin film oven (RTFO) aging simulates 5-10 years of field aging. Pressure aging vessel (PAV) tests push binders to 20+ years of aging. Direct tension tests check low-temp cracking limits. Labs run rotational viscometry to confirm pump temps stay below 175°C during mixing. Missing any test phase can hike road failure risks by 40% in harsh climates.

Meeting PG specs adds 8-15% to material costs but triples road lifespan. Up next: how to pick smart asphalt grades for roads based on traffic loads and weather zones.

Suitable Asphalt Grades for Road Construction

Selecting the right asphalt grade systems ensures roads perform under specific traffic loads and weather conditions. Engineers match grading systems asphalt to project needs using standardized tests and regional climate data.

Optimal Grades for High-traffic Roads

Interstates and truck routes demand asphalt grades with high stiffness. Performance Grading (PG) 76-22 dominates these applications. This grade handles temperatures from -22°F to 76°F while resisting rutting under 18-wheelers. Superpave mixes with 4-6% polymer-modified binders enhance durability. Penetration grades like 60/70 (common in viscosity-based systems) also work for moderate traffic but require thicker layers.

- PG 76-22: 5% elastomeric polymers improve fatigue resistance

- Binder Content: 6.2% minimum for heavy axle loads

- Cost: $85-$110 per ton with modifiers

Grades for Cold Climate Roadways

Regions with sub-zero winters need grading systems for asphalt that prevent thermal cracking. PG 58-28 asphalt performs at -28°F to 58°F, using softer binders that stay flexible. Northern states like Minnesota often pair it with 22% RAP (Recycled Asphalt Pavement). Penetration grades like 40/50 (measured in 0.1mm units) remain viable for secondary roads through viscosity grading.

- PG 58-28: 3% SBS additives prevent low-temperature cracking

- Winter Mixes: Compacted at 250°F vs standard 300°F

- Cost Premium: 12-18% higher than standard PG 64-22

These asphalt grade systems demonstrate how climate and usage dictate material choices. Next, we explore how environmental priorities shape modern grading practices.

Environmental Considerations in Asphalt Grading

Grading systems for asphalt shape how roads affect the earth. The right mix can cut harm and boost green goals. Modern asphalt grade systems balance strength with care for soil, air, and water.

Impact Of Grading on Sustainability

Asphalt grades change how much heat, fuel, or new rock is used. For example, PG 64-22 (a common binder) needs less heat in mild zones, saving 12-15% energy. Stiff grades like PG 76-16 last 20+ years in hot zones, slashing repair trips. Wrong grades cause cracks, leaks, or fast wear, which pollute nearby streams with loose grit.

Eco-friendly Grading Practices

New methods blend old asphalt (RAP) up to 30% into fresh mixes. Warm-mix tech cuts temps by 50°F, lowering CO2 by 15-20%. Tools like life-cycle checks (LCA) help pick grades that trim waste. States like CA now demand at least 15% RAP in state jobs to save cash and curb mining.

These green steps link to how specs ensure asphalt meets both strength and earth care rules.

FAQs: Asphalt Grading Systems

What is the Difference Between PG 64-22 and PG 70-10?

The primary difference between PG 64-22 and PG 70-10 lies in their temperature performance. PG 64-22 is suitable for moderate climates and can withstand maximum pavement temperatures of up to 64°C (147°F) and minimum temperatures down to -22°C (-8°F). In contrast, PG 70-10 is designed for colder climates, enduring maximum temperatures of 70°C (158°F) and minimum temperatures down to -10°F (-23°C), making it more resilient to extreme temperature fluctuations.

How Does Temperature Affect PG Asphalt Performance?

Temperature has a significant impact on the performance of PG asphalt. Higher temperatures can lead to a softer asphalt consistency, increasing the risk of rutting under heavy traffic loads. Conversely, lower temperatures can cause the binder to become too stiff, increasing the likelihood of thermal cracking. PG asphalt grades are formulated to handle specific temperature ranges, ensuring optimal performance throughout the year.

Why Are Multiple Grading Systems Used for Asphalt?

Multiple grading systems are employed for asphalt to address various performance characteristics and environmental conditions. Each grading system—such as Performance Grading (PG), viscosity, penetration, and ductility—provides distinct information about the asphalt’s properties, such as its temperature resistance, flow behavior, and elasticity. This diversity allows engineers to select the most suitable asphalt grade for specific applications, ensuring durability and longevity of the roads under different climate conditions and traffic levels.

Which Grade is Best for Residential Roads?

For residential roads, the best asphalt grade typically depends on the local climate and traffic conditions. Generally, PG 64-22 is recommended for moderate climates, providing good resistance to both summer heat and winter cold. In colder climates, PG 58-28 may be a better choice due to its flexibility at low temperatures, which helps prevent cracking. It’s essential to consider both the local weather patterns and the expected traffic loads when selecting the appropriate grade.

Closing Thoughts

Choosing the right grading system for asphalt is vital for ensuring performance, durability, and safety in construction projects. Different grading methods, such as Performance Grading (PG), viscosity-based grading, and penetration grading, provide insights into the asphalt’s behavior under various conditions.

Understanding key asphalt grades, especially PG 64-22 and PG 70-10, helps in selecting the appropriate material for specific applications. Furthermore, considering environmental impacts and sustainability initiatives boosts efforts in creating eco-friendly structures.

For more detailed information on asphalt grading systems, visit Asphalt Calculator USA to enhance your knowledge and make informed choices for your asphalt projects.