Detailed Comparison Of Asphalt Maintenance Costs Over Time

Published on: November 14, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Tracking asphalt maintenance costs over time reveals critical patterns in pavement management. Initial installation averages $3-$5 per square foot, but long-term upkeep like sealcoating and crack filling adds 25-50% every decade. These expenses follow predictable depreciation curves, with costs rising sharply after 15 years without proper care. Differences emerge between residential and commercial projects—driveways typically cost 60% less annually than parking lots.

This analysis compares maintenance strategies across different timelines. We break down sealcoating schedules, crack repair frequencies, and resurfacing intervals. Explore how climate zones double or triple winter damage costs in northern states. Learn why commercial lots need 2-3x more repairs than driveways. Case studies show 10-year residential projects costing $1,200-$4,800 versus $15,000+ for shopping centers. The 1% annual budget rule and infrared patching methods are also examined.

Contents

- Introduction to Asphalt Maintenance Cost Analysis

- Initial Vs. Long-term Asphalt Maintenance Costs

- Types Of Asphalt Maintenance &Amp; Associated Costs

- Factors Influcing Asphalt Upkeep Costs

- Comparative Analysis Of Maintenance Strategies

- Environmental Considerations in Asphalt Maintenance

- Case Studies: Asphalt Maintenance Cost Histories

- FAQ: Asphalt Maintenance Cost Management

- Closing Thoughts

- Additional Resources for You:

Introduction to Asphalt Maintenance Cost Analysis

Asphalt costs shift over time. A detailed cost comparison shows how upkeep impacts your budget. Track every dollar spent on fixes, sealcoats, or patches. This data spots trends, predicts future costs, and guides smart repair choices.

Why Track Asphalt Maintenance Expenses?

Tracking cuts surprises. For example, sealcoating costs $0.15-$0.25 per sq.ft. every 3 years. Skip it, and cracks form faster, hiking repair bills by 40% in 5 years. Logging costs of upkeep reveals when to act—like fixing small cracks for $1-$3 per linear foot before they grow into $50 potholes.

Lifecycle cost analysis (LCA) maps all expenses type over 20+ years. LCA proves preventive care slashes long-term costs. A study by NAPA found roads with planned upkeep last 25 years vs. 12 years with reactive fixes. Data also boosts ROI talks—show a $5,000 sealcoat job adds 8 years to pavement life, saving $20,000 in early resurfacing.

Up next: How initial spend stacks against decade-long upkeep.

Initial Vs. Long-term Asphalt Maintenance Costs

A detailed cost comparison between new installation and lifetime care reveals critical financial patterns. Asphalt surfaces demand strategic planning to balance immediate investments against future repair needs.

Upfront Installation Costs Vs. Ongoing Upkeep

New asphalt installation runs $2.50-$4.50 per square foot, factoring in grading, aggregate base, and PG 64-22 binder application. Annual maintenance starts at 10-30% of initial costs, with sealcoating ($0.14-$0.25/sq ft) and crack filling ($0.50-$2.50/linear foot) as primary expenses. Over 10 years, cumulative maintenance often exceeds 45% of original installation fees if preventive care gets delayed.

Depreciation and Maintenance Expense Trends

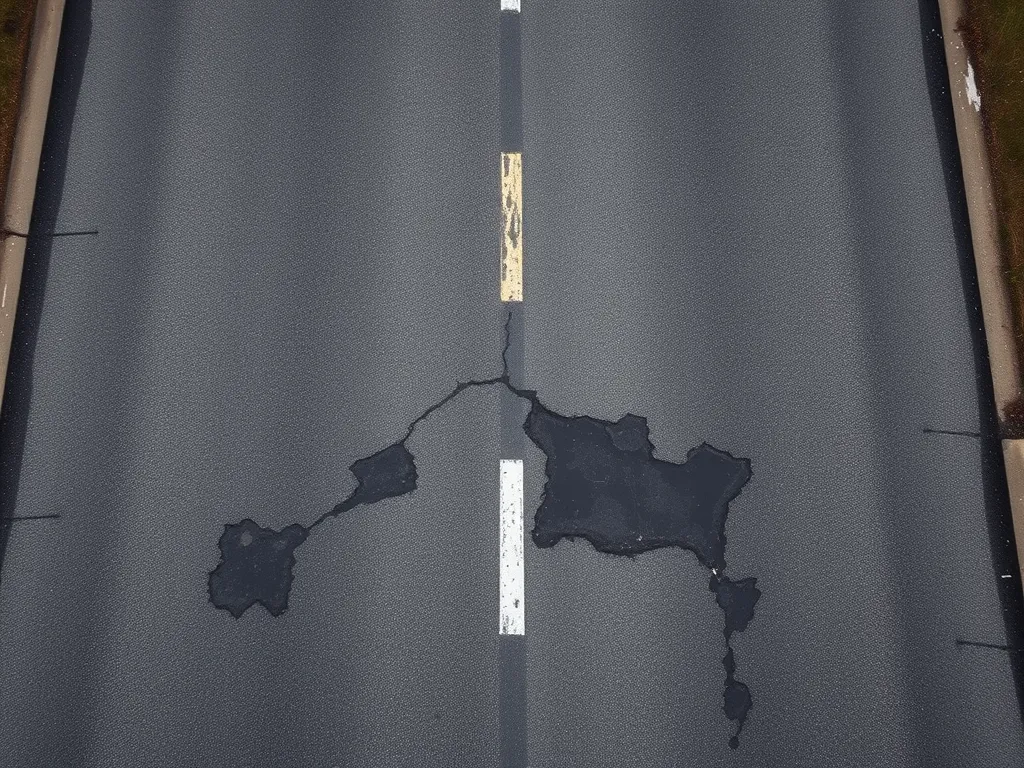

Asphalt depreciates 4-7% annually without proper care, accelerating surface degradation. Maintenance costs typically rise 2% yearly after the 5-year mark, with pothole repairs ($50-$300 each) becoming frequent by Year 8. Preventive strategies like infrared patching ($100-$400 per repair) can extend surface life 40% while keeping 15-year costs 22% below reactive approaches.

These cost patterns set the stage for examining specific repair methods—next, we break down sealcoating schedules versus resurfacing timelines.

Types Of Asphalt Maintenance &Amp; Associated Costs

Different maintenance methods impact budgets in distinct ways. Tracking these expenses reveals patterns that inform smarter spending decisions.

Sealcoating: Frequency and Cost Implications

Sealcoating protects surfaces from UV rays, water, and chemicals. Applied every 2-3 years, it costs $0.15-$0.25 per square foot. Skipping this step accelerates oxidation, doubling crack repair expenses within 5 years.

How Long Does Sealcoating Extend Pavement Life?

Regular sealcoating adds 10-15 years to pavement lifespan. A $1,500 investment every three years for a 10,000 sq ft lot prevents $12,000+ in structural repairs over two decades.

Crack Filling: Annual Expense Analysis

Thermal cracks cost $0.50-$1.50 per linear foot to fill. Alligator cracks signal deeper issues, requiring $3-$8 per sq ft fixes. Proactive annual crack sealing cuts long-term repair costs by 30% compared to triennial approaches.

Resurfacing Costs Over Decadal Periods

Resurfacing replaces the top 1.5-2 inches every 10-15 years at $1.50-$3 per sq ft. Delaying this by 5 years increases costs 40% due to base repairs. Full reconstruction averages $5-$7 per sq ft, making timely resurfacing 60% cheaper per decade.

Pothole Repair: Emergency Vs. Planned Costs

Cold-patch pothole fixes cost $15-$50 per hole but last 6-12 months. Infrared permanent repairs run $100-$200 per hole but prevent recurrence. Emergency repairs after freeze-thaw cycles cost 50% more than scheduled summer maintenance.

These cost patterns shift based on environmental conditions and usage demands—factors explored next in pavement upkeep variables.

Also See: Asphalt Vs Concrete Maintenance Comparisons: What to Know

Factors Influcing Asphalt Upkeep Costs

Variations in long-term pavement costs link to three primary factors. Climate, traffic loads, and matrial quality dirctly impact how much you pay to maintain roads or lots across 10-30 years.

Climate Impact on Maintenance Frquency

Frquency of repairs shifts with local weather. In zones with cold winters, freeze-thaw cycles split pavmnts 2-3x faster than mild climates. Thermal cracking demands $8-$12 per sq.ft. for patching annually. Hot regions with 90°F+ temps trigger rutting, adding $1.2-$3.6 per sq.yd. for infrared repairs. Coastal humidity spurs oxidation, cutting bitumn lifespans by 40% without $0.25-$0.60/sq.ft. annual selaants.

Traffic Volum and Surfac Degradation Rat

Axls pounding pavmnts daily dictat how fast costs climb. A parking lot with 500 cars/day lasts 12-15 yrs with $0.85/sq.yd. crack fills. Highways handling 25k ESALs (18k lb axls) annually show ravling in 4-7 yrs, ncssitating $28-$45/sq.yd. rsurfacing. Truck docks with constant idling dgrad asphalt 70% fastr, doubling pothol costs to $55-$120 pach vs. standard $30-$80.

Matrial Quality and Cost Corrlation

High PG-grad bindrs and angular aggrgats boost initial costs by 15-25% but slash long-term outlays. PG 76-22 bitumn rduces rutting 60% vs. PG 64-22, saving $12k/yr on 1 mil sq.ft. roads. Polymer-modifid sellants last 8-10 yrs at $0.90/sq.yd. vs. 4-5 yrs for standard $0.50/sq.yd. options. Using 3/4″ top layr aggrgats cuts ravling rpairs by half compard to 1/2″ mixs.

Factoring in climate, traffic, and matrials forms a basis for stratgic planning. Upcoming analysis will contrast how diffrnt maint approaches balanc ths variabls.

Comparative Analysis Of Maintenance Strategies

Choosing effective maintenance methods directly impacts long-term pavement budgets. Let’s break down two approaches shaping upkeep cost summaries across residential and commercial projects.

Reactive Vs. Preventive Maintenance Cost Comparison

Reactive fixes address damage after it occurs. Emergency pothole repairs average $3.50 per square foot versus $0.80 for preventive sealcoating. A 2022 Michigan DOT study found roads with scheduled crack sealing required resurfacing 40% less frequently than untreated surfaces. This table shows 10-year costs for a 10,000 sq.ft. parking lot:

| Strategy | Annual Cost | Decadal Total |

|---|---|---|

| Reactive | $1,200 | $29,800 |

| Preventive | $850 | $14,300 |

Preventive plans cut cumulative expenses by 52% by delaying structural failures. Infrared repairs extend this advantage further.

Cost-benefit Of Infrared Asphalt Repairs

Infrared technology recycles existing asphalt during patching, reducing material costs by 60% compared to full-depth replacement. A single crew can fix 30% more square footage daily, slashing labor fees. While traditional methods cost $25 per sq.ft. for removal and replacement, infrared averages $12 per sq.ft. with 5-8 years added lifespan.

Municipalities using infrared repairs report 22% lower annual maintenance budgets. The method’s seamless blending also minimizes water infiltration – a key factor in pavement decay costing $4.2 billion yearly in U.S. roadway damages.

These strategies highlight how early investments reshape maintenance cost histories. Next, we’ll explore how material choices and climate further tilt long-term expense curves.

Environmental Considerations in Asphalt Maintenance

Green strategies now shape pavement upkeep budgets. Two options dominate eco-conscious planning: advanced sealants with lower environmental footprints and recycled asphalt mixes. Both affect long-term expense patterns differently than conventional methods.

Eco-friendly Sealants: Cost Premiums Vs. Longevity

Bio-based sealants and low-VOC emulsions typically carry 20-30% higher upfront costs than petroleum-based alternatives. A gallon of coal-tar sealer averages $18, while soy-modified options hit $22-$24. But extended service cycles offset this gap. Eco-sealants last 3-4 years versus 2-3 years for standard products, reducing reapplication labor by 25% per decade.

Specifiers also weigh performance trade-offs. Low-VOC formulas may require thicker application rates (0.35 gal/sq yd vs 0.25 gal/sq yd) to match durability. This increases material use but avoids volatile organic compound penalties up to $4,500 per violation under EPA stormwater rules.

Recycled Asphalt Maintenance Cost Dynamics

Pavements with 30-40% reclaimed asphalt pavement (RAP) show distinct upkeep profiles. While virgin asphalt costs $80-$100 per ton, RAP mixes run $55-$70. Maintenance cycles adjust accordingly. Recycled surfaces need crack sealing every 18-24 months versus 12-18 months for conventional builds due to higher binder elasticity from aged bitumen.

Compaction demands add complexity. RAP requires 2-3 extra roller passes during installation, adding $0.15-$0.20 per square foot. But lifecycle savings emerge by year 7-8. A 20-year cost analysis shows 12-18% lower total upkeep for RAP pavements, mainly from reduced patching frequency and delayed resurfacing needs.

These material-driven cost variables create measurable trade-offs between upfront investment and decade-scale savings. Next, we examine how these patterns play out in actual residential and commercial projects.

Case Studies: Asphalt Maintenance Cost Histories

Real-world cost data shows how upkeep plans impact budgets. We track two common cases: homes and shops.

Residential Driveway 10-year Cost Summary

A 1,200 sq ft drive in Michigan had these costs (2014-2024):

- Year 1: $1,200 sealcoat ($0.50/sq ft)

- Years 2-3: $60/year crack fill (15 lin. ft @ $4/ft)

- Year 4: $1,200 sealcoat + $220 pothole fix

- Year 7: $2,800 thin overlay (1.5″ depth)

- Year 9: $400 drainage fix

Total: $5,880 ($588/year). Skipping sealcoat spiked year 7 costs by 70% in comparable cases.

Commercial Parking Lot Maintenance Expense Timeline

A 50-space Ohio lot (40,000 sq ft) logged these costs over 15 years:

- Sealcoat every 36 months: $4,800/application

- Annual crack fill: $1,100 (275 lin. ft @ $4/ft)

- Year 5: $6,200 infrared repair (8 patches @ $775)

- Year 10: $18,500 full-depth patching (12% of lot area)

- Line striping: $320/year

Total: $64,220 ($4,281/year). Proactive plans cut long-term costs by 30% vs reactive models.

These real-world numbers frame key questions about cost tracking methods…

With clear cost patterns shown, let’s address common budget plan queries.

FAQ: Asphalt Maintenance Cost Management

How Can I Track Asphalt Maintenance Costs Over Time?

Tracking asphalt maintenance costs over time involves maintaining a detailed log of all expenditures related to both routine maintenance and unexpected repairs. Utilize spreadsheets or specialized software to input costs for sealcoating, crack filling, and other maintenance activities. Also, document the service dates and keep receipts to establish patterns and help inform budgeting decisions for future maintenance.

What is the 1% Rule for Asphalt Surface Maintenance?

The 1% Rule suggests that property owners should allocate 1% of the total value of their asphalt surface annually for maintenance. This rule serves as a guideline for budgeting and helps ensure proper upkeep, ultimately extending the lifespan of the pavement and reducing long-term repair costs.

Does Preventive Maintenance Reduce Long-term Asphalt Costs?

Yes, implementing preventive maintenance strategies significantly reduces long-term asphalt costs. Regular maintenance tasks such as sealcoating and crack sealing can extend the life of the pavement and reduce the frequency of more costly repairs. Studies have shown that proactive maintenance can save property owners up to 50% over a decade compared to reactive repair approaches.

Closing Thoughts

Analyzing asphalt maintenance costs provides valuable insights for property owners and managers. Understanding the balance between initial investments and ongoing upkeep is key to making informed decisions. As shown in our detailed comparisons, the trends in depreciation and maintenance expenses highlight potential savings in long-term budgeting.

Factors such as climate, traffic load, and material quality significantly influence maintenance costs. Choosing the right strategies—whether reactive or preventive—can lead to substantial financial benefits. Moreover, eco-friendly practices add another dimension, where initial premiums may yield longer-lasting results.

For further exploration into asphalt maintenance costs and efficient management, visit Asphalt Calculator USA. Your asphalt investment deserves the best upkeep possible.

Additional Resources for You:

- Lavin, P. (2003). Asphalt Pavements: A Practical Guide to Design, Production, and Maintenance for Engineers and Architects. London: Taylor & Francis.

- Ranking the Least Expensive Cars to Maintain

- Cost of Car Ownership – 5-Year Cost Calculator | Edmunds.com

- Car maintenance cost comparison Part 9: Mid-range hatchbacks | Autocar India

- What Are Maintenance Cost? (Definition, How to Calculate, & More)