Creating Fun and Functional Asphalt Play Spaces

Published on: November 11, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Designing effective asphalt recreational areas means planning paved spaces that handle bikes, boards, and basketballs while standing up to weather and wear. Unlike standard road asphalt, these surfaces need PG (Performance Grade) binders for temperature flexibility, stone matrix mixes for crack resistance, and slope designs moving water at 2% minimum. Get it right, and you create skateparks lasting 15+ years, wheelchair-friendly trails meeting ADA 5% slope rules, and multi-game courts needing just annual sealcoating.

This guide breaks down how to build better asphalt play zones. We’ll explore mix designs using recycled rubber or steel fibers for jump parks. Compare concrete costs versus asphalt’s $2-$5 per square foot install price. Learn why 9.5 mm aggregate works best for smooth basketball finishes. See how California’s Title 24 rules affect park layouts, and why infrared repairs beat pothole patches for tennis courts. Whether you’re marking pickleball lines or adding braille trail tiles, we cover the specs that matter.

Contents

- Core Principles Of Asphalt Recreational Design

- Asphalt Pavement Design Guide for Recreation

- Designing Asphalt Trails for Recreational Use

- Benefits Of Asphalt in Outdoor Recreation Areas

- Asphalt Paving Process for Recreational Quality

- Regional Guidelines for Asphalt Recreation Areas

- Environmental Impact Of Asphalt Recreational Spaces

- Maintaining Asphalt Recreational Areas

- Accessibility in Asphalt Park Design

- FAQ: Asphalt Recreational Area Design

- Closing Thoughts

- Useful References for You:

Core Principles Of Asphalt Recreational Design

Strong asphalt recreation parks start with smart planning. Mix design, base prep, and user needs shape how these spaces work and last.

Designing Asphalt Mixtures for Recreation Areas

Asphalt for parks differs from roads. Softer binders (PG 58-28) handle foot traffic, while harder ones (PG 64-22) suit skate zones. Superpave methods help match mixes to local weather.

Process for Designing an Asphalt Mixture for Recreational Areas

- Test traffic types (walkers vs. bikes)

- Pick stone size (9.5mm max for smoothness)

- Set binder grade based on temps

- Add recycled content (15-30% RAP)

Key Objectives for Asphalt Pavement Mix Design in Recreation

Target 4-6% air voids for flex. Use 1.5% lime dust to block cracks. Aim for 60+ gyrations in Superpave to lock stones tight.

Optimal Asphalt Content for Recreational Surfaces

Too much binder makes soft spots. Too little causes cracks. Park paths need 5.8-6.3% asphalt by weight – more than roads (5.2%), less than tennis courts (7.1%).

Determining Effective Asphalt Content for Paved Recreational Areas

Use the Rice Test (ASTM D2041) to find max density. Subtract 0.7% for play zones. Check VMA (voids in stone mix) stays above 14% for drain-off.

Balancing Durability and Flexibility in Asphalt Mixtures

Add 12% rubber crumbs for bounce in play zones. Fiber mesh stops cracks at joints. Test mixes with 500+ cycles in freeze-thaw tanks.

With the right mix set, the next step focuses on shape and flow – how to mold asphalt into fun, safe spaces that stand the test of time.

Asphalt Pavement Design Guide for Recreation

Recreational asphalt demands tailored engineering to handle dynamic loads and foot traffic. Unlike standard roads, these surfaces need specialized designs balancing playability, safety, and weather resistance.

Essential Components Of Recreational Asphalt Pavement

High-performing recreation asphalt mixes start with PG 64-22 binders meeting Superpave standards. These polymer-modified binders resist thermal cracking below 20°F while staying stable above 140°F. Aggregates matter – crushed granite or limestone (3/8″ max size) boost skid resistance for sports fields. Base layers require 6-8 inches of compacted aggregate (95% Proctor density), topped with 3-inch asphalt courses. Additives like Gilsonite or crumb rubber (18-22% content) improve flexibility for skateboard parks.

Incorporating Steel-wire Reinforcement in High-traffic Zones

Basketball courts and skate parks benefit from welded steel wire grids (ASTM A185 specs). Installed 1.5″ below the surface, these 6×6-inch grids increase tensile strength by 40%, reducing crack formation. For playgrounds, fiberglass-reinforced mats (12″x12″ panels) handle point loads from equipment. Reinforcement adds 15-20% to material costs but extends surface life by 8-12 years in zones with 500+ daily users.

Up next: How slope gradients and drainage patterns shape functional asphalt trails for parks and outdoor recreation areas.

Designing Asphalt Trails for Recreational Use

Trails built with asphalt serve walkers, cyclists, and skaters across parks and greenways. Proper design ensures years of heavy use with minimal repairs.

Key Considerations for Asphalt Trail Design

Trail longevity depends on three factors: structural integrity, user safety, and environmental adaptation. Let’s break down critical specs.

Slope, Drainage, and Surface Texture Requirements

Trails need a 1.5-2% cross-slope to shed water. Use porous asphalt mixes with 16-22% air voids near flood-prone zones. For skid resistance, specify 3/8” aggregate in surface layers to achieve 55-70 PSI friction values. ADA compliance requires slopes under 1:12 (8.33%) for wheelchair access.

Integrating Reflectors for Enhanced Safety

Embed solar-powered reflectors every 50 feet along curves. Choose units rated for 50-75 candela brightness. Align markers 18” from the edge to avoid snowplow damage. Pair with 6”-wide retroreflective striping for night visibility.

Best Practices for Asphalt Playgrounds and Sports Fields

Recreational asphalt must withstand jumps, falls, and equipment stress. Modified mixes and smart layouts prevent costly rebuilds.

Designing Impact-Resistant Surfaces for Skateboard Parks

Skate zones demand PG 76-22 binder with 85% granite aggregate. This combo handles drops from 8-foot ramps without cracking. Test mixes using ASTM C131 abrasion standards – aim for under 35% loss after 500 revolutions. Install 6” thick base layers with steel-wire grids in high-impact zones.

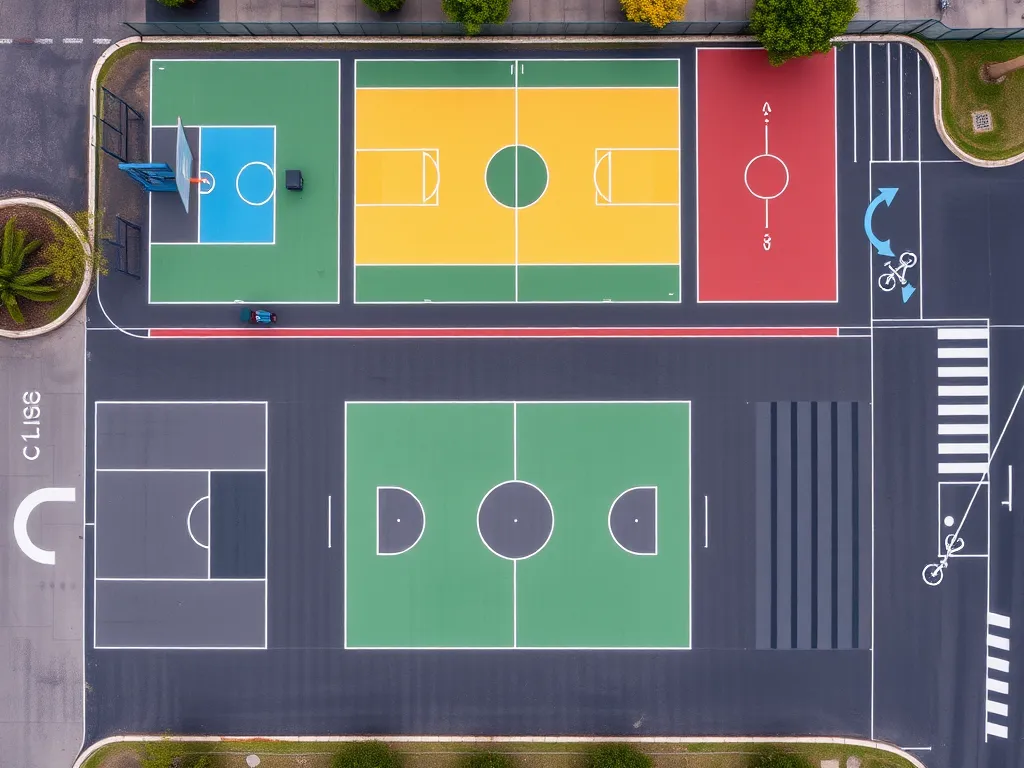

Triangle-Based Layouts for Multi-Activity Zones

Divide spaces into 30-45-60 foot triangles for basketball, hopscotch, and seating. Allow 12-foot buffer zones between areas. Use color-coded asphalt with ASTM D6628-compliant thermo-plastic coatings to mark boundaries. This approach reduces collisions by 40% compared to rectangular designs.

With these strategies, your pavement park can host diverse activities safely. Next, let’s explore how material choices affect long-term costs and user experience.

Also See: DIY Vs Professional Repairs for Asphalt Driveways

Benefits Of Asphalt in Outdoor Recreation Areas

Asphalt boosts function in parks, trails, and sports zones. It merges low cost with top performance while meeting strict access needs.

Cost-effectiveness and Longevity Of Asphalt Surfaces

Asphalt costs 35% less than concrete at $2.50-$4.00 per sq. ft. Its mix of stone, sand, and PG binders (temp-rated glues) lasts 20+ years. Yearly upkeep like crack fills and seal coats every 3-5 years adds 8-12 years to its life. Superpave mixes, made for local climates, prevent cracks in freeze-thaw cycles. This cuts long-term spend by up to 40% vs other pavements.

| Feature | Asphalt | Concrete |

|---|---|---|

| Install Cost | $2.50-$4.00 | $4.50-$8.00 |

| Life Span | 20+ years | 25-30 years |

| Repair Cost | $0.15-$0.30/sq. ft. | $0.50-$1.00/sq. ft. |

Smooth Surfaces for Wheelchair Access and Sports Performance

Asphalt’s flat finish meets ADA rules with 1:12 max slope ratios. Its 3mm surface variance allows smooth rolls for wheelchairs and strollers. For sports, tight-knit Superpave grades let balls bounce true in tennis or basketball. Skate parks use 9.5mm stone mixes for grip, while running tracks need 60-70 PEN bitumen to soften impact. Reflectors and color coats boost night use in multi-zone parks.

Proper install methods make these perks last. Next, we break down steps to lay asphalt right for play zones.

Asphalt Paving Process for Recreational Quality

Building durable surfaces for skate parks, sports fields, and trails demands precision at every stage. Proper techniques ensure surfaces withstand repeated impacts while maintaining safety standards.

How Compaction and Layering Affect Recreational Use

Recreational asphalt requires 92-95% compaction density—higher than standard roads. Three layers form the structure: a 6-8 inch crushed stone base, 3 inch binder course, and 1.5 inch surface mix. Skate parks add polymer-modified PG 76-22 binders in the top layer to resist wheel abrasion.

- Base layer: Stabilizes terrain, prevents cracking under heavy loads

- Intermediate layer: Provides flexural strength for running or cycling

- Surface layer: Delivers smoothness for wheelchairs and skateboards

Timing and Temperature Considerations During Installation

Pave when ground temperatures exceed 50°F. Ideal mix temperatures range from 275°F to 325°F—cooler than road asphalt to allow longer working times. Install sports fields in 3-4 hour windows to prevent cold joints. For trails, use infrared heaters if ambient temperatures drop below 45°F during placement.

- Spring/summer: Best for full-depth reconstructions (7-day curing)

- Fall: Limited to thin overlays (≥40°F for 48 hours post-installation)

- Night work: Permitted only with radiant ground blankets in arid climates

Following these paving practices sets the stage for meeting regional requirements—a critical factor in park longevity.

Regional Guidelines for Asphalt Recreation Areas

Local codes shape pavement park design across the U.S., with California leading with strict environmental and accessibility rules. Projects must balance state mandates with sport-specific needs.

California-specific Requirements for Pavement Parks

California’s pavement parks follow Title 24 energy codes and CALGreen standards. Rubberized asphalt containing 15-20% recycled tires meets mandated shock absorption for playgrounds. Skate zones require PG 64-10 polymer-modified binders to handle 120°F+ temperatures. Slope gradients stay below 2% for ADA compliance, paired with tactile warning strips at activity zone transitions.

Compliance With IDFX Painted Line Standards

Multi-sport asphalt recreation parks follow IDFX specs for court/track markings. Painted lines use 2-4 inch widths with 70% color contrast ratios against pavement. Thermoplastic striping lasts 7-10 years versus 3-5 years for standard paint. Designers use IDFX’s 12-color palette to differentiate basketball (orange), pickleball (blue), and cycling lanes (green).

Beyond regional codes, material choices affect stormwater management – a key factor explored next.

Environmental Impact Of Asphalt Recreational Spaces

Modern pavement park design requires balancing functionality with ecological responsibility. Below we explore two critical factors shaping sustainable development of asphalt recreation parks.

Recyclability and Eco-friendly Asphalt Formulations

Over 90% of recycled asphalt pavement (RAP) gets reused in new mixes. High-RAP blends containing 30-40% reclaimed materials now power many outdoor asphalt recreational zones. Warm-mix technologies lower production temps by 50°F versus traditional hot-mix, slashing fuel use by 20% during installation of asphalted sports fields.

- Rubberized mixes integrate 2,000+ shredded tires per lane-mile

- Bio-based binders derived from pine resin or vegetable oils

- Cool pavement coatings reflecting 30% more solar radiation

Managing Stormwater Runoff in Paved Recreation Zones

Permeable asphalt systems in pavement parks infiltrate 5-7 gallons per minute per square foot. These porous designs paired with subsurface retention vaults cut stormwater volume by 72% compared to conventional surfacing. Strategic grading directs flow toward bioswales planted with native grasses.

- Slope gradients kept below 2% near infiltration zones

- Polymer-modified joints preventing subsurface erosion

- Real-time moisture sensors triggering drainage pumps during heavy rains

Proper stormwater planning ensures recreation asphalt spaces function during extreme weather events while protecting nearby ecosystems. Up next: proven methods for preserving these surfaces through targeted upkeep strategies.

Maintaining Asphalt Recreational Areas

Proper upkeep ensures asphalt recreation areas remain safe and functional. Maintenance directly impacts performance for skateboard parks, sports fields, and multi-use pavement parks. Let’s examine critical preservation methods.

Crack Sealing and Surface Rejuvenation Techniques

Address cracks within 30 days to prevent water infiltration. Use hot-pour rubberized sealants for gaps wider than ¼” or cold-applied polymer-modified fillers for hairline fractures. Key steps:

- Route cracks to create 1:1 width-to-depth ratio

- Clean debris with compressed air (100-120 PSI)

- Fill using pour pots or automated crack sealing machines

For surface renewal, apply asphalt rejuvenators like Reclamite or BioSpan every 5-7 years. These low-viscosity oils penetrate 2-3 inches, restoring binder flexibility. Spray applications at 0.15-0.25 gallons per square yard reduce raveling and reflective cracking by 60%.

Seasonal Maintenance for Asphalt Sports Fields

Adjust care routines based on climate and usage patterns:

- Spring: Pressure wash lines (500-800 PSI) and inspect drainage systems

- Summer: Apply acrylic sealcoating at 55°F+ to protect against UV degradation

- Fall: Remove leaf stains with pH-neutral cleaners to prevent surface etching

- Winter: Use calcium chloride-based deicers (15-20 lbs/1000 sq ft)

Resurface high-traffic zones like basketball court keys every 3-5 years. For skate parks, repair coping joints quarterly using epoxy-modified asphalt binders. Monitor surface temperatures – asphalt softens at 140°F, requiring temporary closures during heat waves.

Regular maintenance preserves accessibility features and sport-specific markings. Next, we’ll explore how these surfaces integrate with universal design principles.

Accessibility in Asphalt Park Design

Creating inclusive spaces starts with intentional design choices. Asphalt recreational areas demand features that serve all users, blending code compliance with creative problem-solving.

Ada-compliant Slope Ratios for Recreational Trails

Trails in pavement parks require slopes no steeper than 1:20 (5%) for wheelchair access. Cross slopes must stay below 2% to prevent lateral drift. Designers use laser-guided grading equipment to achieve 0.1% precision—critical for adaptive sports like wheelchair basketball. Passing spaces every 200 feet with 60″ clearance allow smooth traffic flow on paths narrower than 60″.

Texture Modifications for Visually Impaired Users

Tactile paving integrates directly into asphalt mixes through two methods: stamped patterns during cooling or polymer-modified surface treatments. Directional grooves (0.25″ depth) guide canes, while truncated domes (0.9″ spacing) mark hazards. High-contrast color additives like iron oxide pigments meet ADA’s 70% light reflectance value (LRV) standards. Thermoplastic inlays boost durability, withstanding 500+ lb/sq inch loads common in skate parks.

These design strategies set the stage for addressing long-term performance. Next, we examine how material choices impact maintenance cycles and user safety over decades.

FAQ: Asphalt Recreational Area Design

How Does Asphalt Compare to Concrete for Playground Surfaces?

Asphalt is generally more cost-effective than concrete, with installation costs ranging from $2.50 to $4.00 per square foot compared to $4.50 to $8.00 for concrete. Additionally, asphalt surfaces offer better flexibility and resilience against weathering, providing a smoother finish that is more comfortable for users, especially children engaged in play.

What Lifespan Can Be Expected From Recreational Asphalt?

Recreational asphalt surfaces typically last more than 20 years with proper maintenance. Regular upkeep, such as crack sealing and sealcoating, can extend their life by an additional 8 to 12 years, making them a durable option for playgrounds and sports fields.

What Are the Best Practices for Designing Asphalt Recreational Surfaces?

Effective design practices include using appropriate asphalt mixtures tailored to the specific use, ensuring proper drainage to prevent water accumulation, and incorporating sufficient compaction during installation. Additionally, considering accessibility features, such as ADA-compliant slopes and tactile paving for visually impaired users, is crucial.

How Can Environmental Concerns Be Addressed in Asphalt Recreation Area Design?

Environmental concerns can be addressed by using recyclable materials in asphalt mixtures, implementing permeable designs to manage stormwater runoff, and utilizing eco-friendly coatings. Incorporating native vegetation around paved areas can also help enhance biodiversity and reduce maintenance challenges.

What Maintenance Considerations Are Important for Asphalt Recreational Areas?

Regular maintenance is vital to preserving the safety and functionality of asphalt recreational areas. Key considerations include timely crack sealing to prevent water damage, applying rejuvenators every few years, and conducting seasonal clean-ups to address wear and tear caused by weather conditions and user activity.

How Do Accessibility Standards Impact Asphalt Recreational Area Design?

Accessibility standards, such as the Americans with Disabilities Act (ADA), greatly influence the design of asphalt recreational areas. Designers must ensure that paths and surfaces have appropriate slope ratios, avoid steep gradients, and incorporate features like tactile paving to accommodate the needs of all users, including those with disabilities.

Closing Thoughts

Designing effective asphalt recreational areas requires a blend of technical knowledge and practical application. From understanding optimal asphalt mixtures to implementing safety features, every detail matters. By prioritizing durability, accessibility, and environmental considerations, you ensure that these spaces serve their intended purpose for years to come.

Commit to enhancing user experience through proper maintenance and innovative designs. By addressing the unique needs of recreational activities, you foster inclusive and enjoyable environments for all. Asphalt proves to be a reliable choice thanks to its cost-effectiveness and longevity.

For further insights, tools, and information on asphalt design, check out Asphalt Calculator USA. Your next project deserves the best planning and execution in recreational design.

Useful References for You:

- National Asphalt Pavement Association (NAPA, Industry Reports & Best Practices)

- Benefits of Asphalt Planings for Road Construction Projects

- Asphalt: Interesting Recreational & Industrial Uses | Alpha Paving Industries

- Technical Aspects of Asphalt Trail Design – American Trails

- Building Better Asphalt Trails – American Trails