Asphalt Mix Production Methods: Which One Works Best?

Published on: November 1, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Comparing asphalt mix production methods—like Hot Mix Asphalt (HMA), Warm Mix Asphalt (WMA), Cold Mix Asphalt (CMA), and Ultra-Thin Asphalt Concrete (UTAC)—reveals key differences in environmental impact, cost, durability, production speed, equipment needs, and material compatibility. HMA requires high temperatures (300-350°F) and emits more CO2 but lasts 15-20 years. WMA uses additives to lower temps to 250-275°F, cutting fuel costs by 20-35%. CMA works at ambient temps, costs 30% less upfront, but needs repairs 3x faster. UTAC uses polymer-modified binders for thin, flexible layers ideal for urban roads.

This article breaks down how these methods stack up. Learn which technique suits heavy traffic highways vs. rural driveways. Compare machinery costs for batch plants versus portable recyclers. See why PG (Performance Graded) binders matter for temperature zones. Get data on energy use per ton, maintenance timelines, and recycling rates. We’ll cover material specs, safety protocols, and real-world examples from interstate paving to pothole patches.

Contents

- Introduction to Asphalt Mix Production Methods

- Primary Asphalt Mix Production Techniques

- Performance Comparison Of Asphalt Mix Methods

- Cost Analysis Of Asphalt Production Methods

- Equipment and Material Requirements

- Grades and Classifications Of Asphalt Mixes

- Energy Consumption and Environmental Impact

- Safety Considerations in Production

- Frequently Asked Questions (FAQ)

- Closing Thoughts

- Additional Resources for You:

Introduction to Asphalt Mix Production Methods

Road construction relies on distinct asphalt mix production methods to match project goals. Four primary techniques dominate: Hot Mix Asphalt (HMA), Warm Mix Asphalt (WMA), Cold Mix Asphalt (CMA), and Ultra-Thin Asphalt Concrete (UTAC). Each approach varies in mixing temps, material formulas, and installation protocols.

HMA operates at 300-350°F, binding aggregates with PG 64-22 asphalt. WMA cuts temps by 50-100°F using additives like foaming agents. CMA works at ambient temps with cutback asphalt or emulsified binders. UTAC applies thin layers (0.6-1.2 inches) with polymer-modified binders for fast traffic reopening.

Mix selection impacts road longevity, costs, and carbon output. Highway jobs often pick HMA for its 20-year lifespan. City roads might opt for WMA to trim fuel bills by 30%. CMA suits temporary fixes, costing $25-$40 per ton. UTAC installation runs $3-$5 per square foot but skips milling.

Up next: A breakdown of how these asphalt mix production methods stack up in real-world applications.

Primary Asphalt Mix Production Techniques

Four core methods dominate modern paving projects. Each technique balances temperature, material science, and project needs. Let’s break down how these processes work.

Hot Mix Asphalt (HMA)

HMA remains the industry standard for high-traffic roads. Produced between 300°F and 350°F, it combines aggregates with PG binders—performance-graded bitumen tailored to climate conditions. Drum plants dominate production, heating materials continuously. While offering superior density (92-96% compaction), HMA requires 20-25% more fuel than newer methods. Typical uses: interstate highways, airport runways.

Warm Mix Asphalt (WMA)

WMA slashes production temps to 212°F-284°F using additives like organic waxes or chemical surfactants. This cuts fuel use by 30% and lowers CO₂ emissions by 15-20 tons per 10,000 tons produced. Compatible with existing HMA plants, WMA extends paving seasons into colder months. Ideal for city streets where fumes matter.

Cold Mix Asphalt (CMA)

CMA skips heating entirely. Emulsified bitumen binds aggregates at ambient temps. Though less dense (80-85% compaction), it’s workable year-round. Stockpile stability lasts up to 6 months. Costs run $35-$50 per ton—40% cheaper than HMA. Best for pothole repairs or rural roads with under 500 vehicles daily.

Ultra-thin Asphalt Concrete (UTAC)

UTAC layers measure 0.8″-1.2″ thick with polymer-modified binders. Produced at 320°F, it needs specialized pavers for precise 0.5″ lifts. Despite thin profiles, UTAC handles 5-7 million ESALs (Equivalent Single Axle Loads). Noise reduction hits 3-5 decibels versus traditional mixes. Common in urban resurfacing where traffic disruptions must stay minimal.

With these techniques established, let’s measure how they hold up under real-world stresses. Next, we’ll pit durability stats against climate challenges.

Performance Comparison Of Asphalt Mix Methods

Choosing a way to make asphalt impacts how long roads last, how much cash is spent, and how well pavements handle traffic. This part breaks down how main asphalt mix production methods stack up in critical areas.

Durability and Structural Integrity

Hot Mix Asphalt (HMA) leads with a 15-20 year lifespan due to high compaction at 300°F. Its thick layers (4+ inches) handle heavy trucks, making it fit for interstates. Warm Mix Asphalt (WMA) lasts 12-15 years but may show rutting faster under constant 18-wheeler traffic. Cold Mix Asphalt (CMA) works for temporary patches, lasting 6-12 months before needing replacement. Ultra-Thin Asphalt Concrete (UTAC) uses polymer-modified binders to match HMA’s strength at 1.2-1.6 inches thick, ideal for resurfacing.

Temperature Tolerance and Climate Suitability

| Method | Production Temp | Climate Fit |

|---|---|---|

| HMA | 300-350°F | Hot, dry zones |

| WMA | 200-250°F | Cool, humid areas |

| CMA | Ambient | Wet, freezing conditions |

| UTAC | 265-280°F | Moderate climates |

WMA’s lower temps cut thermal cracking risks in regions with winter lows below 20°F. CMA stays pliable in freezing weather but softens above 85°F. UTAC’s thin profile requires stable temps between 40-90°F to avoid warping.

Application-specific Performance Metrics

HMA supports 30+ million equivalent single-axle loads (ESALs) on highways. WMA handles 10-15 million ESALs on urban roads with stop-and-go traffic. CMA manages under 500,000 ESALs, mainly for pothole repairs. UTAC withstands 3,000+ daily vehicles on suburban streets but isn’t built for truck lanes. Mixes using PG 76-22 binders (common in WMA and UTAC) resist rutting better in high-traffic zones than PG 64-16 blends.

Up next: How these performance factors influence paving budgets, from initial outlays to upkeep over 10+ years.

Also See: Can You Paint Asphalt? Tips for a Flawless Finish

Cost Analysis Of Asphalt Production Methods

Breaking down expenses for asphalt mix production methods reveals critical differences in budgeting. Each technique carries unique financial impacts based on materials, energy use, and project scale.

Initial Production Costs by Method

Hot Mix Asphalt (HMA) averages $100-$150 per ton, requiring high-temperature plants (290-330°F) that hike fuel costs. Warm Mix Asphalt (WMA) cuts temperatures by 50-100°F using additives like Sasobit or zeolites, trimming energy bills 20-35% but adding $3-$8 per ton for chemicals. Cold Mix Asphalt (CMA) skips heating entirely, slashing initial costs to $50-$80 per ton but limiting use to temporary fixes. Ultra-Thin Asphalt Concrete (UTAC) demands premium polymer-modified binders, pushing prices to $180-$220 per ton.

Long-term Maintenance Costs

HMA’s high-density surface lasts 15-20 years but cracks faster in freeze-thaw zones, needing seal coats every 3-5 years ($0.15-$0.30 per sq ft). WMA’s lower production heat reduces binder aging, extending resurfacing cycles by 2-4 years. CMA patches typically fail within 12-18 months, doubling repair frequency. UTAC’s 1.2-inch thickness requires 40% less material over time, with lifecycle savings up to 30% compared to traditional overlays.

Cost Efficiency for Small Vs. Large Projects

HMA plants need 500+ ton batches to offset setup costs, making them ideal for highways or parking lots. CMA’s portable equipment suits pothole repairs under 10 tons, avoiding plant fees. WMA hits its stride in mid-sized projects (50-200 tons), balancing fuel savings against additive expenses. UTAC shines in urban resurfacing where lane closures cost $5,000+ per hour—its rapid installation cuts labor hours 60%.

These cost factors set the stage for evaluating machinery and material needs across methods. Up next: how equipment choices shape production outcomes.

Equipment and Material Requirements

Each asphalt mix production method needs specific tools and inputs. These choices shape costs, speed, and project success.

Machinery for HMA Vs. WMA Production

Hot mix asphalt (HMA) uses drum plants heating stone to 300°F-350°F. Warm mix asphalt (WMA) adds foaming kits or wax to cut temps by 50°F-100°F. Both need burners, dryers, and silos. WMA saves fuel but needs extra gear like water tanks for foam. HMA plants cost $500k-$2M. WMA kits add $50k-$100k.

Aggregate and Binder Specifications

HMA uses sharp, clean stone (1/2″ sieve) with PG 64-22 binder. WMA works with softer binders (PG 58-28) due to lower heat. Cold mix needs smaller stone (3/8″) and emulsified bitumen. Stone must pass 95% on sieve tests. Binder content ranges 4%-6% by weight for HMA/WMA, 6%-8% for cold mix.

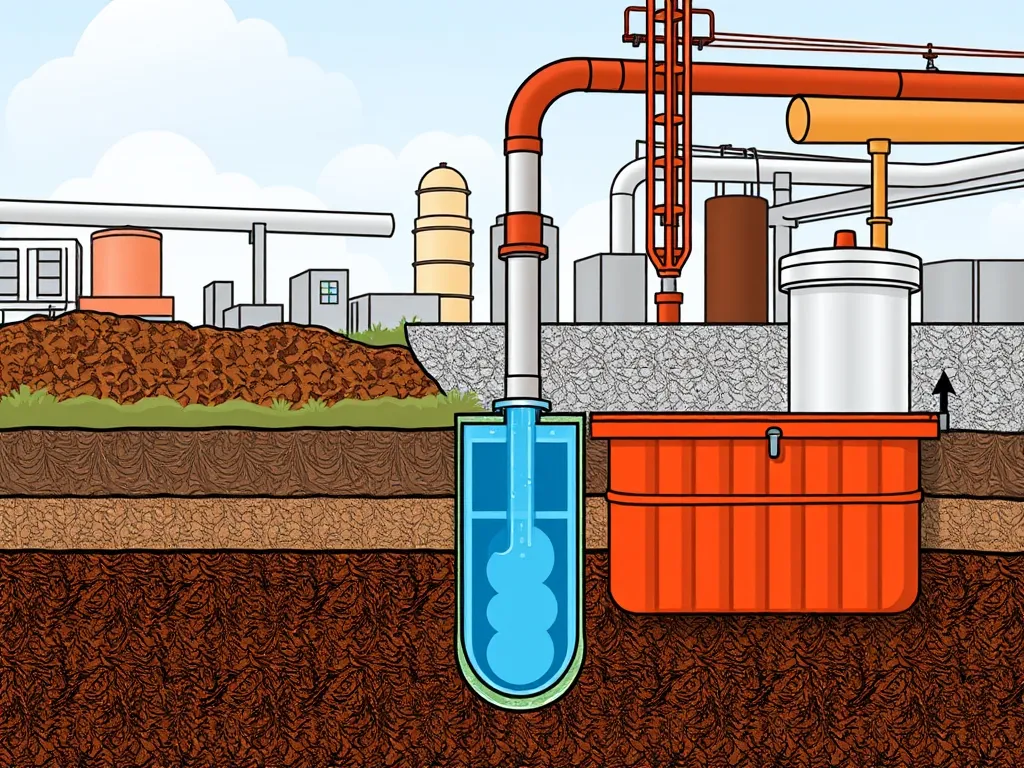

Cold Mix Asphalt Material Handling

Cold mix needs no heat. Stockpile it for weeks in dry spots. Use basic loaders and graders. Additives like lime boost bond strength. Curing takes 1-3 days. Cold mix gains 80% strength in 7 days vs. HMA’s 24-hour cure. Costs drop 30% by skipping heaters.

With gear and specs set, the next step is sorting mix types by grade and class.

Grades and Classifications Of Asphalt Mixes

Asphalt mix grades dictate production methods. Material ratios, heating levels, and compaction techniques shift based on classification. Matching the right mix type to project specs ensures optimal performance and cost control.

Understanding Asphalt Mix Types

Mix types define aggregate size, binder content, and ideal applications. Production adjustments include temperature ranges, mixing duration, and equipment settings. Type 3, 4, 6, and 7 mixes dominate roadwork across scales.

Type 3 vs. Type 4 Asphalt

Type 3 uses finer aggregates (3/8″ max size) and higher binder content (5.5-6.5%). It requires shorter mixing cycles at 300-325°F for sidewalks or bike paths. Type 4 has larger stones (1/2″ max) and lower binder (4.5-5.5%), needing extended mixing at 325-350°F for arterial roads. Batch plants often alternate between these by adjusting screens and burner settings.

| Feature | Type 3 | Type 4 |

|---|---|---|

| Aggregate Size | 3/8″ | 1/2″ |

| Binder Content | 5.5-6.5% | 4.5-5.5% |

| Typical Use | Pedestrian paths | High-traffic roads |

Type 6 vs. Type 7 Asphalt

Type 6 serves as a base layer with 3/4″ aggregates and 4-5% binder. Drum plants produce it at 275-300°F for parking lots. Type 7, a surface mix, uses 1/2″ stones and 6-7% binder. It demands precise temperature control at 300-325°F in batch plants for driveways. Recycling rates differ: Type 7 allows 20-30% RAP (reclaimed asphalt pavement), while Type 6 permits 40-50%.

Class A Vs. Class B Asphalt Differences

Class A contains 6-7% binder (PG 64-22 grade) and requires high-precision drum plants. It’s mixed at 325-350°F for interstate highways. Class B uses 4-5% binder (PG 58-28) and tolerates batch plant production at 300-325°F. Local roads often use Class B for its 15-20% lower cost per ton. Compaction standards vary: Class A needs 92-95% density, Class B targets 88-90%.

Material choices in these classifications shape energy use and equipment wear. Next, we examine how production setups handle environmental demands.

Energy Consumption and Environmental Impact

Asphalt mix production methods vary in energy demands and ecological footprints. The choice between hot, warm, cold, or ultra-thin techniques shapes both operational costs and planetary impacts. Let’s break down the numbers.

Carbon Emissions by Production Method

Hot Mix Asphalt (HMA) dominates emission charts, releasing 16-22 kg of CO₂ per ton during 300-330°F heating. Warm Mix Asphalt (WMA) slashes this by 20-35% through chemical additives or foaming processes that cut temps to 220-280°F. Cold Mix Asphalt (CMA) operates at ambient temps, emitting just 3-5 kg CO₂/ton but suits only temporary repairs. Ultra-Thin Asphalt Concrete (UTAC) balances emissions at 12-15 kg CO₂/ton through reduced material use and faster layering.

Recyclability and Sustainable Practices

HMA plants now routinely blend 20-30% Reclaimed Asphalt Pavement (RAP), while WMA accommodates up to 50% RAP due to lower heat stress. CMA struggles with recycled content (max 15%) but excels in low-energy patching. Emerging techniques like asphalt rubber (AR) using ground tire rubber (GTR) boost sustainability – some states mandate 15% GTR in mixes. The National Asphalt Pavement Association reports 94% of RAP gets reused, saving 60 million tons of virgin aggregate yearly.

These environmental factors directly influence project specifications and compliance with EPA regulations. Next, we’ll examine how safety protocols adapt to each production method’s unique risks.

Safety Considerations in Production

Safety protocols vary across asphalt mix production methods. Each technique presents unique risks tied to temperature, material handling, and application processes. These factors directly impact worker protection and project outcomes.

High-temperature Mix Handling Protocols

Hot mix asphalt (HMA) requires heating aggregates and bitumen to 300°F–350°F. Workers face burn risks from hot materials and equipment. Thermal gloves, face shields, and flame-resistant clothing are mandatory. Plants use automated systems to minimize direct contact during mixing and transport. Warm mix asphalt (WMA) operates at 225°F–275°F, reducing fume exposure but still demanding heat-resistant gear. Both methods require strict air quality monitoring due to hydrocarbon emissions.

Cold Mix Storage and Application Safety

Cold mix asphalt (CMA) uses emulsified binders that cure at ambient temperatures. While eliminating burn hazards, storage demands care. Keep CMA in sealed containers to prevent water infiltration or binder separation. During application, avoid prolonged skin contact with emulsifiers containing solvents like naphtha. Ventilate enclosed spaces to disperse fumes during mixing. CMA’s lower fire risk allows faster project turnaround but requires attention to chemical safety data sheets (SDS).

These safety factors influence method selection across projects. Next, we explore how material choices and protocols shape common industry questions.

Frequently Asked Questions (FAQ)

What Are the Key Factors to Consider When Choosing an Asphalt Mix Production Method?

When selecting an asphalt mix production method, consider factors such as the project’s traffic load, climate conditions, cost constraints, desired lifespan, and environmental impact. Different methods like HMA, WMA, CMA, and UTAC offer varying degrees of performance based on these criteria.

How Do the Production Temperatures Affect the Quality Of Asphalt Mix?

Higher production temperatures, like those used in Hot Mix Asphalt (HMA), generally lead to better compaction and durability. However, they also increase energy consumption and emissions. Lower temperatures in methods like Warm Mix Asphalt (WMA) can be beneficial for reducing environmental impact but may affect binder aging and potential density.

What is the Role Of Additives in Asphalt Production?

Additives play a crucial role in modifying the properties of asphalt mixes. For example, in Warm Mix Asphalt production, additives can lower the mixing temperature, enhance workability, and reduce emissions. Special polymers and other materials may also be incorporated into Ultra-Thin Asphalt Concrete (UTAC) to improve performance characteristics.

How Does Each Asphalt Mix Method Perform in Different Weather Conditions?

Hot Mix Asphalt (HMA) is best suited for hot and dry climates; Warm Mix Asphalt (WMA) performs well in cooler conditions; Cold Mix Asphalt (CMA) is ideal for wet or freezing conditions as it remains workable without heating; Ultra-Thin Asphalt Concrete (UTAC) requires moderate temperatures for optimal performance.

Are There Any Regulations Governing Asphalt Mix Production?

Yes, various regulations dictate the production of asphalt mixes, particularly concerning emissions and environmental impact. Compliance with local, state, and federal environmental regulations is essential, particularly as they relate to carbon emissions and material recycling practices.

What Maintenance Practices Are Recommended for Different Asphalt Mix Types?

Maintenance practices vary by mix type. For example, Hot Mix Asphalt typically requires seal coating every 3-5 years, while Cold Mix Asphalt may need more frequent repairs. Warm Mix Asphalt and Ultra-Thin Asphalt Concrete can offer longer intervals between maintenance due to their inherent properties, but each method will require periodic inspections and minor repairs based on specific usage and climate conditions.

Closing Thoughts

Comparing different asphalt mix production methods reveals unique strengths and weaknesses for each technique. Hot Mix Asphalt (HMA) offers durability but requires higher temperatures, whereas Warm Mix Asphalt (WMA) provides energy savings and a cooler production process. Cold Mix Asphalt (CMA) is superb for immediate repairs, while Ultra-Thin Asphalt Concrete (UTAC) excels in applications where surface smoothness is key.

Cost analysis shows that initial production costs vary, with HMA generally being more expensive than WMA. Over time, maintenance expenses can also differ based on the specific needs of each pavement type. Therefore, selecting the right method depends on project requirements, climate, and budget considerations.

Understanding equipment needs and material specifications is vital for effective production. Safety protocols, especially for HMA handling, play a crucial role in protecting workers and ensuring quality outcomes. The environmental impact, through carbon emissions and recyclability, also weighs into the decision-making process for asphalt mix selection.

For comprehensive tools and resources about asphalt calculations and methods, check out Asphalt Calculator USA.

Additional Resources for You:

- Yoder, E. J., & Witczak, M. W. (1975). Principles of Pavement Design (2nd ed.). New York, NY: Wiley.

- Street Works | Different Types of Asphalt Mixes and When To Use Them

- 5 Different Types of Asphalt Mixes | Bituminous Roadways Blog

- How To Choose The Right Asphalt Mix

- 6 Asphalt Plant Types: Matching Production to Project Scope • Heavy Equipment Appraisal