Asphalt Thickness Guide: What You Need for Driveways, Roads & More

Published on: October 30, 2025 | Last Updated: April 14, 2025

Written By: George Voss

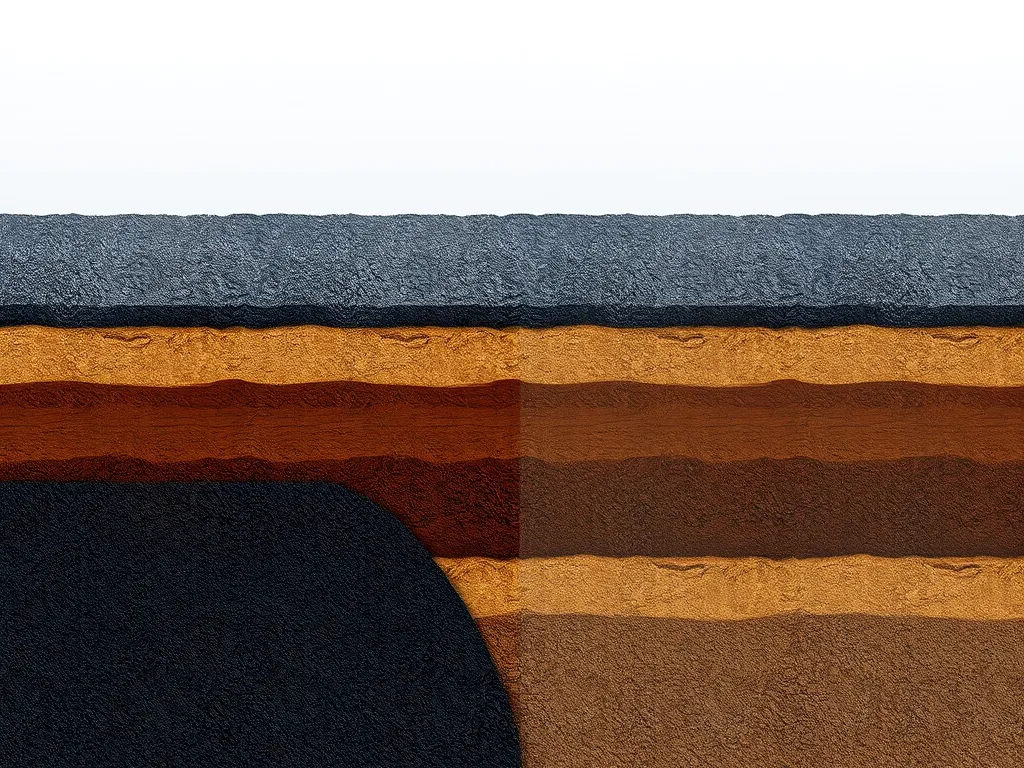

Asphalt thickness varies significantly by application, directly impacting durability, load capacity, and project costs. Residential driveways typically use 2-3 inches of hot mix asphalt over 6 inches of aggregate base, while interstate highways require 4-6 inches of asphalt on 12+ inches of compacted stone. Optimal thickness depends on traffic volume (cars vs. 18-wheelers), material types (PG 64-22 binders for cold climates), and climate conditions (freeze-thaw cycles). Underestimating thickness can lead to premature cracks; overestimating wastes $1.50-$3.00 per square foot in material costs.

This guide breaks down asphalt depth requirements for 15+ uses – from tennis courts (1.5-2 inches) to container yards (8+ inches). We compare mix types (9.5mm vs. 12.5mm aggregates), subgrade prep methods (geotextile fabrics vs. lime stabilization), and climate adaptations (porous asphalt for flood zones). Cost tables show how thickness choices affect budgets: adding 1 inch to a 10,000 sq ft parking lot increases materials by $15,000-$30,000. Regional specs from AASHTO and ASTM are included for all 50 states.

Contents

- Introduction to Asphalt Thickness Requirements

- Asphalt Thickness for Different Applications

- Key Factors Influencing Asphalt Thickness

- Cost Implications Of Asphalt Thickness Variations

- Environmental Considerations in Thickness Selection

- Regional Differences in Asphalt Thickness Requirements

- FAQ: Common Questions About Asphalt Thickness

- Closing Thoughts

- Useful References for You:

Introduction to Asphalt Thickness Requirements

Asphalt thickness determines how long pavements last under daily wear. Thinner layers save money upfront but crack faster under weight or weather. Thicker layers handle heavier loads but cost more per square foot. Getting this balance right requires knowing traffic patterns, soil types, and climate demands.

Why Proper Asphalt Thickness Matters

Roads with 3 inches of asphalt crumble under truck traffic, while 6-inch driveways waste funds. The asphalt base thickness acts as the backbone: too thin, and potholes form; too thick, and budgets balloon. For example, parking lots need 3-4 inches over 8-12 inches of base, while highways require 9-12 inches total. Frost-prone zones add 20% more depth to resist freeze-thaw cycles.

Engineers use AASHTO design charts to match asphalt thickness for roads with projected ESALs (Equivalent Single Axle Loads). A residential street sees 10,000 ESALs yearly, needing 5-7 inches. An industrial zone with 1 million ESALs needs 10+ inches. Subgrade strength matters too: clay soils demand thicker bases than gravel-rich soils. A 6% error in depth cuts pavement life by 30%.

Next, explore how driveways, highways, and storage yards each demand unique asphalt layers thickness.

Asphalt Thickness for Different Applications

Properly sizing asphalt layers ensures durability under specific loads. Let’s break down thickness needs by use case.

Residential Applications

Driveways and Home Parking Areas

Driveways typically use 2-3 inches of hot mix over 4-6 inches of crushed stone base. Light vehicles like sedans require less structural depth than RVs. The asphalt thickness for driveway rises to 3.5 inches in freeze-thaw zones to prevent cracking.

Private Roads and Sidewalks

Private roads handling under 500 vehicles daily need 3-4 inches of surface mix. Sidewalks use thinner profiles: 1.5-2 inches over compacted gravel. Both benefit from polymer-modified binders to resist weathering.

Commercial Applications

Parking Lots and Business Streets

Parking lots require 3-5 inches of Type B asphalt over 8-12 inches of base. High-traffic zones like fuel stations use PG 64-22 binder mixes. The parking lot asphalt thickness often includes two layers: 1.5-inch leveling course plus 2-inch wear course.

High-Traffic Commercial Zones

Delivery docks or truck terminals need 6-8 inches of dense-graded Superpave mixes. These zones use 12.5 mm aggregate blends to handle 18,000+ lb axle loads. Rut-resistant designs prevent deformation under constant use.

Industrial Applications

Heavy-Duty Pavements and Storage Yards

Ports or container yards install 8-12 inches of asphalt over stabilized subgrades. Open-graded friction courses (OGFC) improve drainage under static loads. Steel-reinforced layers handle forklifts exceeding 50,000 lbs.

High-Temperature Mix Requirements

Refinery pavements use PG 76-22 binders rated for 170°F+ surface temps. Mixes include 1% hydrated lime to resist fuel/oil degradation. Base layers exceed 18 inches in high-load zones.

Roadway Applications

Local Roads vs. Highways

Local roads use 4-6 inches of 9.5 mm mix over 8-inch bases. Interstate highways require 8-12 inches of 12.5 mm Superpave with 20-year design lives. The asphalt road thickness directly correlates with ESAL (Equivalent Single Axle Load) counts.

Grocery Store Parking Lots

These need 4-5 inches of SMA (Stone Mastic Asphalt) to withstand shopping cart traffic. Reflective crack interlayers are installed beneath the surface to prevent joint failures.

Recreational Uses

Tennis/Basketball Courts and Golf Courses

Sports surfaces use 1.5-2 inches of fine-graded mix over porous bases. Golf cart paths require 3 inches of polymer-modified asphalt with textured finishes for slip resistance. Colorized topcoats enhance visibility.

Next, we’ll explore how mix designs, soil prep, traffic loads, and climate shape these thickness guidelines.

Key Factors Influencing Asphalt Thickness

Asphalt layer depth depends on four core factors: mix type, soil strength, traffic weight, and weather. Each plays a role in how thick to lay asphalt for long-term use.

Asphalt Mix Types and Gradation

Mix recipes change how thick asphalt layers need to be. Gradation (stone size spread) affects load spread and wear life.

Hot Mix vs. Cold Mix Asphalt Layer Thickness

Hot mix (HMA) binds at 300°F. Used for roads, it needs 3-4 inch base layers. Cold mix sets at air temp. For patch jobs, 1-2 inch layers work but wear faster.

9.5 vs. 12.5 Asphalt Mix Differences

9.5 mix has smaller stones (3/8″ max). It’s smoother for top coats – 1.5″ thick on driveways. 12.5 mix uses ½” stones. Better for base layers at 3″ depth under heavy truck lanes.

Type A vs. Type B Asphalt Applications

Type A has more binder for flex. Needs 2.5″ min on busy streets. Type B uses less binder. Saves cost at 2″ thick for home drives with light cars.

Subgrade Soil Quality and Preparation

Weak soils (clay/silt) need 6-8″ asphalt total. Strong soils (gravel/sand) cut depth to 4-5″. Always compact soil to 95% density first. Add 6″ gravel base if soil rates below CBR 5.

Expected Traffic Loads (Residential, Commercial, Industrial)

Car tires? 2″ surface layer works. Semi trucks? 4″ hot mix over 8″ base. Forklifts in yards? 6″ base plus 3″ top. Each 10k daily cars adds 0.5″ to road thickness needs.

Climate and Environmental Impacts

Freeze zones need 5-6″ total to stop cracks. Use PG 64-22 binder in cold. Hot states use PG 76-16 binder at 3″ depth to resist rutting. Wet areas add 1″ to base for drainage.

These factors shape both asphalt road thickness and cost. Next, we break down how depth choices hit your budget.

Also See: How Asphalt is Evolving to Combat Climate Change

Cost Implications Of Asphalt Thickness Variations

Thicker asphalt layers boost durability but increase material costs. Every extra inch adds $0.50-$1.25 per square foot based on mix type and regional pricing. Let’s break down how thickness choices impact budgets across applications.

Balancing Durability and Budget

Residential driveways (2-3 inches) cost $3-$5 per sq ft versus 8-12-inch highway asphalt road thickness at $8-$15 per sq ft. Commercial parking lot asphalt thickness typically uses 3-4 inches ($4-$7 per sq ft) to handle daily traffic without overspending.

| Application | Typical Thickness | Cost Range/Sq Ft | Lifespan |

|---|---|---|---|

| Driveways | 2-3″ | $3-$5 | 12-20 years |

| Parking Lots | 3-4″ | $4-$7 | 15-25 years |

| Highways | 8-12″ | $8-$15 | 20-30 years |

Subgrade preparation cuts costs long-term. Weak soils need 6-8 inches of aggregate base – adding $1.20-$2 per sq ft – but let you reduce asphalt base thickness by 15-20%. Hot mix asphalt layer thickness requires 300°F compaction for maximum density, saving 8-12% in lifecycle repairs versus cold mixes.

Thin surface layers wear faster. A 2-inch asphalt driveway thickness lasts 8-10 years under heavy trucks, while 3 inches extends service to 15 years. PG 64-22 binders in 12.5 mm mixes boost crack resistance for high-traffic zones, justifying higher initial costs.

Next, we’ll examine how material efficiency ties to both budgets and environmental goals.

Environmental Considerations in Thickness Selection

Picking the right asphalt layer for roads and pavements affects more than just strength. Thick layers use more raw materials. Thin layers may fail fast. Both choices impact the earth.

Sustainability and Material Efficiency

Life-cycle studies show proper asphalt thickness cuts waste. A 3-inch asphalt driveway thickness lasts 12-15 years. Thicker layers (4+ inches) add cost but may not boost life span. Lean designs save 15-20% raw stone and bitumen per project.

Recycled asphalt pavement (RAP) mixes reuse old roads. RAP lets crews build base layers up to 6 inches thick with 30% less new rock. Top layers still need fresh binder for smooth surfaces. Each 10% RAP added cuts CO2 by 1.2 tons per mile.

| Use Case | Eco-Friendly Thickness | Material Savings |

|---|---|---|

| Home driveways | 2.5-3 inches | 18% less vs. 4-inch |

| Parking lots | 4 inches with porous base | 22% less runoff |

| Local roads | 5.5 inches (2 lifts) | 12% RAP usable |

Hot asphalt layer thickness also shapes energy use. Thick mats need longer burn times. A 9.5 mix cures faster than 12.5 – cutting fuel use by 8% per ton. New warm-mix tech allows 275°F pours vs 325°F, slashing fumes.

Local soil and weather patterns guide green choices. Next, we’ll see how regions adapt asphalt road thickness to their unique needs.

Regional Differences in Asphalt Thickness Requirements

Asphalt thicknesses shift dramatically across the United States. Local climate zones, soil conditions, and freeze-thaw cycles demand tailored designs. A parking lot in Phoenix won’t need the same specs as one in Minneapolis.

Climate and Soil Adaptations

Extreme temperatures reshape asphalt layer needs. Northern states like Minnesota use thicker asphalt pavements (4-6 inches) with deeper crushed stone bases (8-12 inches) to combat frost heave. Southern states opt for 3-4 inches of surface mix but lean on polymer-modified PG 76-22 binders to resist rutting at 100°F+ temperatures.

| Region | Climate Factor | Surface Thickness | Base Layer |

|---|---|---|---|

| Midwest | Freeze-thaw cycles | 4-6″ | 8-12″ granular base |

| Southwest | High heat | 3-4″ | 6-8″ with geotextile |

| Coastal Southeast | Heavy rainfall | 4-5″ | Open-graded drainage layer |

Soil type dictates base thickness. Clay soils with low California Bearing Ratio (CBR) scores below 5% require 30% thicker bases than sandy soils (CBR 10-20%). Coastal zones add lime stabilization to weak subgrades before laying asphalt layers.

Superpave mix designs adapt to these variables. High-traffic zones in wet climates use 12.5 mm mixes for better density, while arid regions choose 9.5 mm gradations. Polymer additives or fibers boost crack resistance without adding depth.

Next, let’s tackle the most frequent queries about balancing these variables.

FAQ: Common Questions About Asphalt Thickness

What is the Best Thickness for Asphalt for Various Applications?

The best thickness for asphalt varies based on the specific application. For residential driveways, it is typically 2-3 inches, while commercial parking lots usually require 3-5 inches. Heavy-duty industrial pavements often need 8-12 inches, especially in areas with high traffic loads or extreme conditions.

How Does Climate Affect the Required Asphalt Thickness?

Climate plays a significant role in asphalt thickness requirements. In colder regions with freeze-thaw cycles, thicker asphalt layers (typically 4-6 inches) are necessary to prevent cracking. Conversely, warmer climates may require thinner layers (around 3-4 inches) to accommodate heat and prevent rutting.

How Do Soil Conditions Influence Asphalt Thickness Choices?

Soil conditions are crucial in determining asphalt thickness. Weak soils, such as clay, require thicker asphalt layers (6-8 inches) to support the weight and prevent deformation. In contrast, stronger soils like gravel may allow for reduced thickness (4-5 inches) due to their enhanced load-bearing capacity.

Are There Specific Thickness Requirements for Recreational Uses?

Yes, recreational uses such as tennis or basketball courts generally require 1.5-2 inches of asphalt. Golf cart paths typically need around 3 inches of polymer-modified asphalt to ensure durability and adequate slip resistance.

What Should I Consider When Choosing Asphalt Thickness for High-traffic Areas?

When selecting asphalt thickness for high-traffic areas, consider the expected traffic loads, the type of vehicles (e.g., trucks vs. cars), and the asphalt mix used. High-traffic areas often necessitate thicker layers (6-8 inches) made from dense-graded mixes to withstand significant wear and tear over time.

What is the Impact Of Adding Recycled Asphalt Pavement (RAP) to Asphalt Thickness?

Incorporating recycled asphalt pavement (RAP) can reduce the need for new materials and may allow for thinner asphalt layers while maintaining durability. Using RAP helps save on costs and demonstrates eco-friendliness while achieving similar performance standards.

Closing Thoughts

Asphalt thickness plays a pivotal role in ensuring the longevity and functionality of pavements across various applications. From residential driveways to high-traffic commercial zones, selecting the correct thickness is essential for performance and longevity.

Understanding the specific needs of each application, along with factors such as soil quality, traffic load, and climate, allows for informed decisions. Proper asphalt selection and thickness can enhance durability while managing costs effectively.

For more information on asphalt calculations and to access helpful resources, visit Asphalt Calculator USA.