Common Misconceptions About Hot Mix Asphalt: Separating Fact From Fiction

Published on: October 23, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Hot mix asphalt (HMA) is a high-performance paving material made of 95% stone, sand, or gravel (aggregates) bonded by 5% asphalt cement heated to 300-350°F. Despite myths, HMA lasts 15-20 years with proper care, works in temperatures from -40°F to 120°F, and gets reused in 99% of U.S. road projects. Modern mixes use PG binders (performance-graded for specific climates) and Superpave designs to handle heavy trucks or residential driveways equally well.

This article tackles eight persistent myths about HMA. You’ll learn why thickness alone doesn’t guarantee longevity, how cold-weather paving works, and why recycled asphalt (RAP) cuts costs by 20-30% without sacrificing quality. We’ll break down technical details like mix temperatures, environmental impacts, and maintenance schedules—all in plain terms.

Contents

- What is Hot Mix Asphalt?

- Myth: Hot Mix Asphalt Has a Short Service Life

- Myth: Hot Mix Asphalt is Only Suitable for Highways

- Myth: Hot Mix Asphalt Cannot Be Used in Cold Weather

- Myth: Hot Mix Asphalt is Too Expensive

- Myth: All Asphalt Mixes Are the Same

- Myth: Hot Mix Asphalt Poses Significant Environmental Hazards

- Myth: Hot Mix Asphalt Requires No Maintenance

- Myth: Thicker Asphalt Layers Always Last Longer

- FAQs About Hot Mix Asphalt Myths

- Closing Thoughts

- Useful References for You:

What is Hot Mix Asphalt?

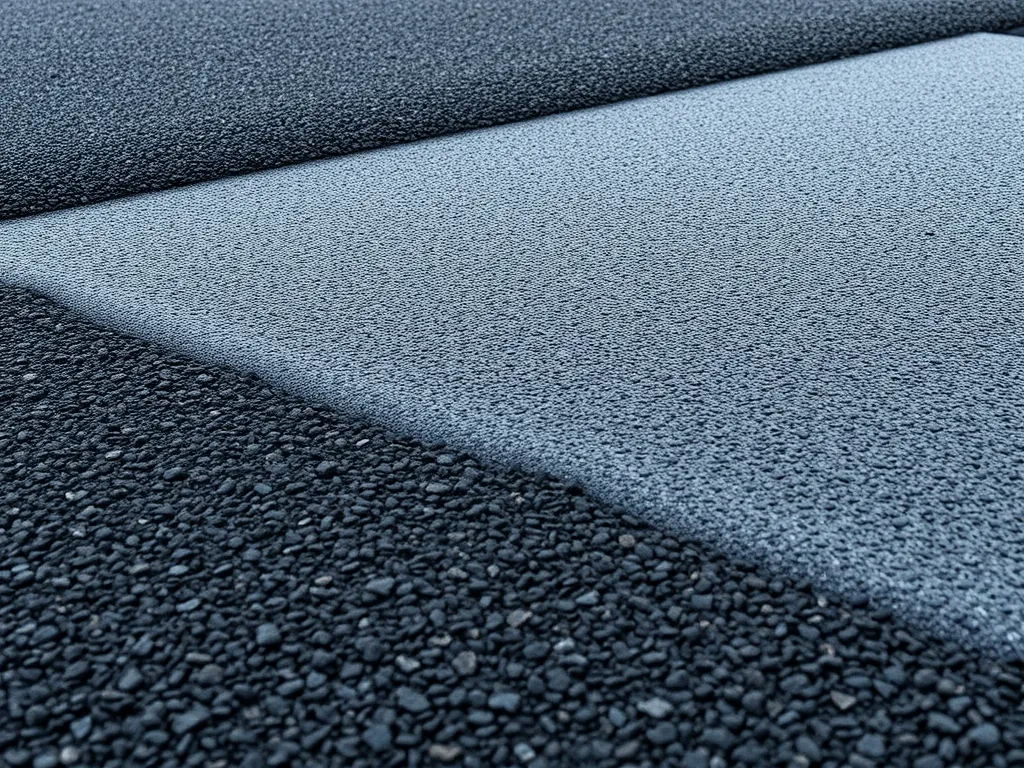

Hot mix asphalt (HMA) forms the backbone of modern paved surfaces. This engineered material combines precise ratios of stone, sand, and asphalt binder heated to 300-350°F during production. Properly mixed and compacted, it creates smooth, weather-resistant layers that handle heavy loads.

Composition and Production Basics

HMA contains 90-95% aggregates (crushed rock, gravel, sand) and 5-10% asphalt binder. The binder acts as glue, derived from crude oil refining. Modern plants use PG (Performance Graded) binders tested under Superpave specifications to match regional climate demands. Mixes are designed for specific traffic loads – a 3/4″ thick surface layer withstands 10,000+ daily vehicle passes on highways.

Primary Applications in Paving

While highways dominate HMA use, over 30% of production goes to residential/commercial projects. Driveways use finer-graded mixes like SM-9.5A for car traffic, while parking lots require sturdier SM-12.5D mixes. Municipalities opt for HMA on bike paths and playgrounds due to its smooth finish. Recycled asphalt pavement (RAP) now makes up 15-30% of new mixes, cutting costs by $3-$10 per ton.

With clarity on HMA’s science and scope, let’s tackle persistent myths about its durability.

Myth: Hot Mix Asphalt Has a Short Service Life

Many believe hot mix asphalt (HMA) fails fast. This myth ignores real data and best use cases. Let’s set the record straight.

How Long Does Hot Mix Asphalt Actually Last?

HMA lasts 15-20 years with basic care. High-traffic roads need resurfacing every 10-15 years. Driveways often hit 20+ years with yearly checks. The key? Mix design and upkeep.

Factors Influencing Longevity

| Factor | Impact |

|---|---|

| PG binders (heat/cold rated) | Boost crack resistance by 30-40% |

| Base prep (300mm+ graded stone) | Prevents 80% of potholes |

| Traffic load (cars vs trucks) | Trucks cut life by 3-5 years |

| Climate (freeze-thaw cycles) | Adds $1.50/sq.yd in annual fixes |

Proper Maintenance Practices

Fix cracks yearly to block water. Seal coat every 3-5 years ($0.15-$0.25/sq.ft). Fill potholes fast with HMA patches. Check drains to stop base washouts. These steps slash repair costs by 50%.

Durability myths fade when facts hit the road. Next, let’s tackle where HMA works best beyond big highways.

Myth: Hot Mix Asphalt is Only Suitable for Highways

Many associate hot mix asphalt (HMA) solely with interstate roads due to its heavy traffic endurance. This limited view ignores its engineered adaptability across multiple settings.

Versatility in Residential and Commercial Use

HMA’s composition—95% aggregates and 5% liquid asphalt cement—allows precise customization. Contractors adjust aggregate gradation or PG (Performance Graded) binders to match project needs. Residential driveways use finer aggregates for smoother finishes, while commercial sites prioritize coarser blends for load-bearing strength.

Parking Lots, Driveways, and Walkways

- Driveways: HMA withstands freeze-thaw cycles and vehicle weight at 2-3 inch thicknesses. Proper compaction ensures 15-20 year lifespans with sealcoating every 3-5 years.

- Parking Lots: Stone-matrix asphalt mixes handle 18-wheelers without rutting. Infrared repairs fix localized damage faster than concrete replacements.

- Walkways: Warm-mix asphalt variants install at 50°F lower temps, reducing thermal cracking in pedestrian zones.

Cost plays a role too. HMA averages $2-$5 per square foot installed—20-30% cheaper than concrete. Its rapid curing (24-48 hours) minimizes business downtime during lot renovations.

Up next: Debunking temperature limits—learn why HMA works even in sub-50°F climates with modern paving methods.

Also See: Asphalt Paving in Cold Weather: Tips for Success

Myth: Hot Mix Asphalt Cannot Be Used in Cold Weather

Many assume hot mix asphalt (HMA) work stops once frost hits. This belief stems from rigid mixing and paving rules tied to thermal conditions. Modern methods now allow cold-weather HMA applications with planning.

Temperature Requirements for Installation

HMA must stay above 275°F during mixing and 220°F when laid. Ground must hit 50°F minimum to avoid rapid cooling. PG (Performance Graded) binders adjust viscosity for varying climates. In northern zones, contractors use heated transfer trucks and infrared rays to maintain mix warmth during transit. Paving can occur in air temps as low as 40°F if base layers stay frost-free.

Adaptations for Seasonal Challenges

Winter HMA jobs demand tactical shifts. Warm mix asphalt (WMA) additives cut mixing temps by up to 50°F through surfactants or wax. Thermal blankets shield fresh mats from freezing air. Windbreaks limit rapid cooling on sites. States like Minnesota and Alaska now use WMA with 15-20% RAP (Recycled Asphalt Pavement) in cold months without sacrificing structural capacity.

Beyond cold-weather installation tactics, financial factors also shape HMA choices. Up next: how initial costs stack up against long-term gains.

Myth: Hot Mix Asphalt is Too Expensive

Many assume hot mix asphalt (HMA) carries high costs without considering its full financial picture. Initial outlays might look bigger than options like gravel or chip seal, but HMA’s life cycle costs frequently win against rival materials.

Cost Comparison With Alternatives

HMA typically runs $2.50-$4.00 per square foot installed, while concrete hits $6-$10 for similar work. Gravel sits at $1-$3 initially but demands annual grading and fresh stone layers. HMA also installs in days, not weeks, cutting labor bills. For roads handling 500+ cars daily, HMA’s structural capacity avoids costly base repairs common with lighter materials.

Long-Term Value and Durability

With 15-20 years of service before major fixes, HMA outlasts gravel by 3x and rivals concrete’s lifespan at half the upfront cost. A 2021 NCAT study found HMA roads cost 30% less per year than concrete when factoring in crack sealing, joint repairs, and surface grinding. Modern mixes with polymer-modified binders or recycled materials boost longevity further. PG-graded binders (performance-graded for climate) and perpetual pavement designs push lifespan past 25 years in ideal conditions.

While cost often drives paving choices, material capabilities matter just as much. Up next: why assuming all asphalt mixes work alike can lead to costly mistakes.

Myth: All Asphalt Mixes Are the Same

Many believe asphalt mixes function identically across projects. This assumption ignores critical engineering distinctions tailored to climate, traffic, and structural demands. Hot mix asphalt (HMA) and cold mix asphalt serve vastly different purposes despite sharing core ingredients.

Key Differences Between Hot Mix and Cold Mix Asphalt

HMA combines aggregates (crushed stone, sand) with heated bitumen at 275°F–325°F. The high-temperature process ensures proper viscosity for compaction, creating dense surfaces rated for 15–20 years. Cold mix uses emulsified bitumen or cutback asphalt, applied at ambient temperatures. It’s softer, designed for temporary repairs, and lasts 6–12 months.

- Production: HMA requires heated plants; cold mix blends at room temperature

- Curing: HMA hardens within hours; cold mix takes days

- Strength: HMA withstands 3,000–5,000 PSI loads; cold mix handles under 1,500 PSI

When to Choose Hot Mix Over Cold Mix

Select HMA for projects needing durability under heavy use or extreme weather. High-traffic roads, airport runways, and commercial parking lots demand its tensile strength. In regions with freeze-thaw cycles, HMA resists cracking better due to PG (Performance Graded) binders engineered for specific climates. Cold mix suits emergency pothole fixes or rural driveways with light traffic.

Though HMA costs $100–$200 per ton versus $50–$80 for cold mix, its lifespan cuts long-term expenses by 30–50%. Install HMA when temperatures stay above 40°F to ensure proper adhesion. Contractors use infrared heaters in colder months to maintain workable heat levels during placement.

Beyond material science, modern asphalt practices also prioritize sustainability—a factor often overlooked in hot mix asphalt myths. Next, we’ll examine how recycling transforms this material’s environmental impact.

Myth: Hot Mix Asphalt Poses Significant Environmental Hazards

Many believe hot mix asphalt harms ecosystems and contributes to pollution. This myth stems from outdated practices, not modern production methods.

Recycling and Sustainability Practices

Hot mix asphalt leads the construction industry in recyclability. Over 95% of reclaimed asphalt pavement (RAP) gets reused in new mixes. Producers integrate RAP with virgin aggregates and PG binders—performance-graded asphalt cement tailored to climate needs. This cuts material waste by 30-50% per project while maintaining structural integrity.

Reducing Pollution Through Modern Techniques

Warm-mix asphalt (WMA), a variant of hot mix, lowers production temperatures by 50°F–100°F. Less heat means 20% fewer greenhouse gas emissions and reduced energy use. Porous asphalt mixes also manage stormwater, filtering pollutants and replenishing groundwater. Technologies like infrared heaters during repairs further minimize emissions by targeting specific areas.

Next, let’s tackle the belief that hot mix asphalt needs zero upkeep—a myth that risks costly repairs if ignored.

Myth: Hot Mix Asphalt Requires No Maintenance

A common myth about hot mix asphalt claims it functions optimally without upkeep. This false assumption often leads to avoidable harm. While hot mix asphalt (HMA) is built to withstand heavy loads and harsh conditions, skipping routine care drastically cuts its functional span.

Essential Care for Longevity

HMA’s durability links directly to proactive maintenance. Annual inspections catch minor issues before they grow. Tasks like sealcoating—applying a protective layer—shield surfaces from oxidation and UV rays. Proper drainage checks stop water pooling, which weakens structural integrity. Ignoring these steps risks premature cracks, rutting, or alligatoring.

Repairing Cracks and Potholes Effectively

Addressing damage swiftly prevents costly rebuilds. Hairline cracks under ¼ inch need liquid crack fillers to block moisture. Larger gaps require hot rubberized asphalt for flexibility. Potholes demand full-depth patching: removing debris, compacting sub-base layers, and filling with HMA at 300°F. Infrared patching melts existing asphalt for seamless bonding, cutting labor costs by 15-20%. Annual crack sealing can prolong pavement life by up to 7 years.

How thick should asphalt layers be for optimal results? Our next section challenges assumptions linking thickness directly to lifespan.

Myth: Thicker Asphalt Layers Always Last Longer

Many assume thicker asphalt automatically means longer-lasting pavement. While thickness matters, it’s just one factor in a complex engineering equation. Over-thick layers waste materials and money without improving performance.

Balancing Thickness With Structural Needs

Engineers design hot mix asphalt layers using the AASHTO 1993 Guide or newer Mechanistic-Empirical Pavement Design methods. These systems calculate required depths based on:

- Traffic loads (ESALs – Equivalent Single Axle Loads)

- Subgrade soil strength (CBR values between 3-20)

- Material properties (PG 64-22 vs PG 76-16 binders)

A residential driveway typically needs 2-3 inches, while interstate highways require 8-12 inches. Adding extra inches without proper analysis provides no structural benefit.

Optimizing Design for Traffic and Climate

Climate dictates layer composition more than thickness alone. Northern states use PG 58-28 binders for freeze-thaw resistance, while southern states opt for PG 70-22 to resist rutting. High-traffic areas combine:

| Traffic Level | Base Layer | Surface Layer |

|---|---|---|

| Residential | 6″ aggregate | 1.5″ HMA |

| Commercial | 8″ aggregate | 3″ HMA |

| Industrial | 12″ aggregate | 4″ HMA |

Modern Superpave mixes let engineers tailor asphalt performance without excessive depth. Stone Matrix Asphalt (SMA) surfaces last 15-20 years at 2-inch depths when properly compacted to 93% density.

Costs rise $0.50-$1.25 per square foot for each unnecessary inch added. Smart designs save 18-35% on initial installation while matching or exceeding lifespan expectations.

While layer thickness grabs attention, true pavement performance comes from precise engineering – a reality we’ll explore next when examining environmental impacts.

FAQs About Hot Mix Asphalt Myths

What Are the Disadvantages Of Warm Mix Asphalt?

While warm mix asphalt (WMA) has several advantages, including reduced emissions and lower production temperatures, it may not be suitable for all applications. Some disadvantages include potential limitations in durability under heavy loads and its performance in extreme weather conditions, as it may not offer the same rigidity and strength as hot mix asphalt (HMA). Additionally, the initial costs can sometimes be comparable to HMA, limiting its financial appeal for certain projects.

Is Hot Mix Asphalt Hazardous During Installation?

Hot mix asphalt (HMA) can pose safety risks due to high temperatures involved in its production and application. Workers must use appropriate safety gear, including heat-resistant gloves and boots, to prevent burns. Additionally, inhalation of fumes can be harmful, emphasizing the need for proper ventilation and use of masks during installation. Proper training and safety protocols are essential to minimize these risks.

Can Hot Mix Asphalt Be Recycled?

Yes, hot mix asphalt (HMA) is highly recyclable. In fact, over 95% of reclaimed asphalt pavement (RAP) is reused in new asphalt mixes. This process not only reduces construction waste but also conserves natural resources. The integration of RAP with virgin materials allows for cost-effective paving solutions while maintaining the quality and performance expected from HMA.

Closing Thoughts

Hot mix asphalt stands as a reliable choice for various paving needs, yet misconceptions often cloud its true potential. From longevity to versatility, understanding these myths helps in making informed decisions. By debunking false beliefs, we can appreciate hot mix asphalt’s effectiveness, cost efficiency, and suitability for both residential and commercial applications. Whether you’re planning a new driveway or a large-scale road project, knowledge is key.

For more information and resources on hot mix asphalt and to better equip yourself with accurate insights, check out Asphalt Calculator USA.

Useful References for You:

- Kett, I. (1999). Asphalt Materials and Mix Design Manual. Oxford: Elsevier Science.

- Hot Mix Vs. Cold Mix Asphalt: What’s The Difference?

- Understanding the differences between hot mix asphalt and warm mix asphalt

- Common Misconceptions About Asphalt Paving: Expert Insights

- What Are The Different Types Of Asphalt Hot Mix?