Cold Mix Asphalt for Commercial Parking Lots: Quick Fixes & Budget-friendly Surfaces

Published on: October 14, 2025 | Last Updated: April 14, 2025

Written By: George Voss

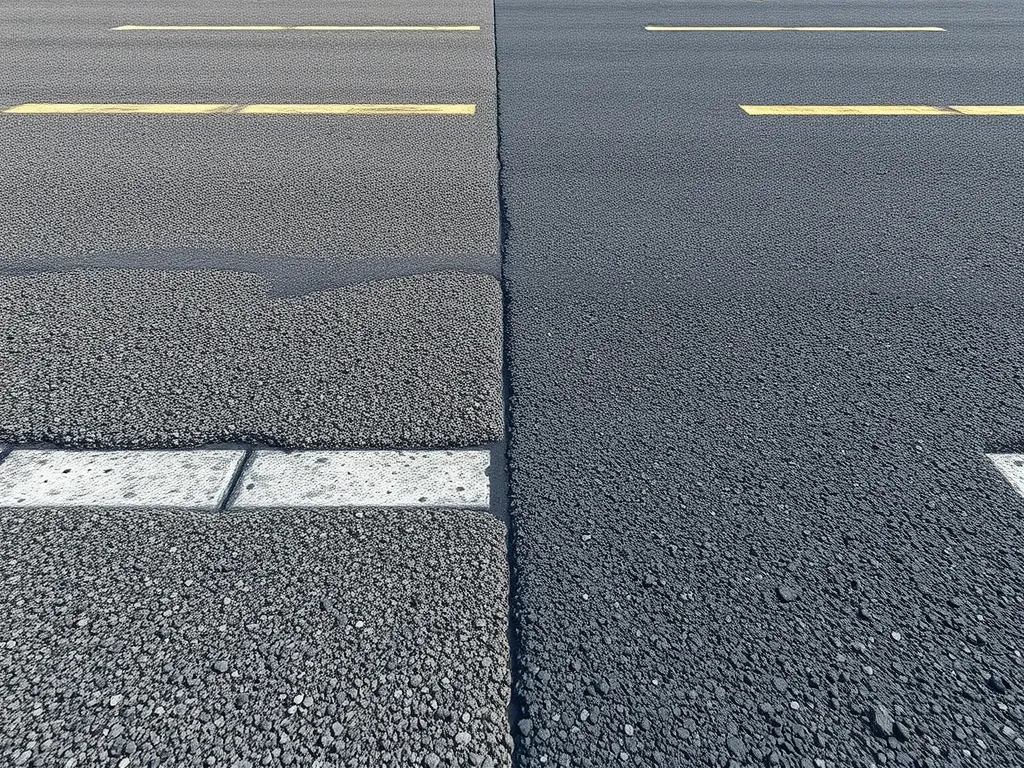

Cold mix asphalt is a ready-to-use paving material designed for fast repairs and temporary surfaces in commercial parking lots. Made with aggregates coated in emulsified asphalt (a blend of bitumen and water), it cures without heat—unlike hot mix asphalt, which requires heating to 300°F. Property managers use cold mix for pothole patches, edge repairs, and temporary access areas because it works in rain, snow, or temperatures as low as 40°F. While hot mix lasts longer under heavy traffic, cold mix costs 30-50% less and can be driven on immediately.

This guide covers how cold mix asphalt performs in commercial parking lots. You’ll learn when to choose it over hot mix or concrete, proper installation steps for lasting results, and cost-saving tips for large projects. We’ll also compare durability data, thickness requirements for trucks vs. cars, and eco-friendly recycled options.

Contents

- What is Cold Mix Asphalt?

- Applications Of Cold Mix Asphalt in Parking Lots

- Advantages and Limitations

- Cold Mix Asphalt Vs. Other Options

- Technical Specifications for Parking Lots

- Installation and Cost Factors

- Environmental Considerations

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

What is Cold Mix Asphalt?

Cold mix asphalt is a ready-to-use paving material designed for repairs and surfacing without heat. Unlike traditional hot mix, it uses emulsified binders that cure at ambient temperatures. This makes it ideal for quick fixes in commercial parking lots, especially during colder months or wet conditions.

Composition and Production

Cold mix asphalt combines three core components: aggregates (crushed stone or gravel), bitumen emulsion (a liquid asphalt binder), and additives like polymers or solvents. Aggregates make up 70–85% of the mix, while bitumen emulsion accounts for 4–10%. Additives improve adhesion and curing speed.

| Component | Percentage | Role |

|---|---|---|

| Aggregates | 70–85% | Structural base |

| Bitumen Emulsion | 4–10% | Binder |

| Additives | 1–5% | Enhance workability |

Production occurs at 50–80°F, far lower than hot mix’s 300°F. Aggregates are coated with emulsified bitumen, creating a pliable material that hardens over time. Polymer-modified variants (e.g., ASTM D4215-approved mixes) offer stronger bonds for heavy traffic areas.

Key Uses in Commercial Settings

Cold mix asphalt for commercial parking lots excels in three scenarios: emergency repairs, temporary surfaces, and low-traffic zones. Retail centers, warehouses, and office complexes use it for:

- Filling potholes in high-traffic lanes

- Patching cracks near loading docks

- Creating temporary access routes during construction

It’s also used for edge repairs around curbs and storm drains, where machinery access is limited. While not a permanent solution for primary lanes, it extends pavement life at 40–60% lower cost than hot mix for minor fixes.

Next, we’ll explore how these applications translate to real-world parking lot projects, including permanent versus temporary strategies.

Applications Of Cold Mix Asphalt in Parking Lots

Cold mix asphalt serves as a versatile solution for commercial parking areas needing quick fixes or adaptable surfaces. Its unique formula works across seasons and traffic patterns, making it a go-to for property managers.

Primary Commercial Uses

From emergency repairs to planned maintenance, cold mix asphalt addresses common challenges faced by parking lot operators. Its flexibility shines in two key areas.

Pothole Repairs and Surface Patching

Cold mix asphalt bonds with existing pavement at ambient temperatures, making it ideal for filling potholes or patching cracks in commercial lots. Unlike hot mix, it requires no heating equipment—simply compact the material into cleaned voids. For small repairs (under 6” deep), cold mix provides a fast, budget-friendly fix at $0.15-$0.30 per pound. Polymer-modified blends extend durability, handling up to 500 vehicles daily.

Temporary vs. Permanent Parking Lot Solutions

Standard cold mix works for temporary patches during winter months when hot mix plants close. For permanent repairs, opt for high-performance mixes containing cationic asphalt emulsion or rubberized additives. These variants achieve 85-90% density after compaction, lasting 2-5 years under moderate traffic. Always specify “permanent cold mix” with 3/8” aggregate for load-bearing areas near accessible parking spaces.

Comparing Cold Mix to Hot Mix Asphalt

While hot mix remains the standard for new parking lot construction, cold mix dominates specific scenarios. The choice hinges on four factors: temperature, traffic, timeline, and budget.

When to Choose Cold Mix for Parking Lots

Select cold mix asphalt for parking lots when:

- Ambient temperatures drop below 50°F (hot mix requires 275-325°F application)

- Repairs must be completed within 4 hours (no curing downtime)

- Budget constraints limit spending to $1.50-$3.00 per square foot

- Traffic volumes stay under 1,000 vehicles daily

For lots with semi-truck traffic or ADA ramp areas, combine cold mix with a 2” hot mix overlay for enhanced durability.

While cold mix asphalt serves multiple roles in parking lot maintenance, weighing its performance against project requirements determines long-term success. Up next: how cost and climate factors shape its advantages over other materials.

Advantages and Limitations

Cold mix asphalt for parking lots offers unique pros and cons for commercial use. Weigh these factors before picking it for your site.

Benefits Of Cold Mix Asphalt for Parking Lots

Cold mix asphalt for commercial parking lots shines in speed, cost, and flex. It suits fast fixes and tight budgets.

Cost-Effectiveness and Quick Installation

Cold mix asphalt cuts costs by 30-50% vs hot mix. No heat gear cuts labor hours. Crews lay 500-800 sq ft per hour. Stockpile it for months – no waste from cooling.

All-Weather Application

Apply cold asphalt mix from 20°F to 120°F. Additives bond in rain or snow. Hot mix fails below 40°F. Patch potholes same-day in storms – keep lots safe.

Disadvantages Of Cold Mix Asphalt

Cold mix asphalt parking lots trade speed for strength. Know the limits before full-scale use.

Durability Considerations

Cold mix lasts 1-3 years vs hot mix’s 7-10. Heavy trucks cause rutting. Use for temp lots or low-traffic zones. Seal every 6-12 months to boost life. Mix in lime or cement for high-load spots.

Cold mix asphalt for commercial parking works best when matched to site needs. Next, see how it stacks up against hot mix, concrete, and chip seal for long-term plans.

Also See: Benefits Of Asphalt Driveways: 5 Key Advantages

Cold Mix Asphalt Vs. Other Options

Pick the right stuff for your lot. Let’s break down how cold mix asphalt stacks up.

Cold Mix Vs. Hot Mix Asphalt

Hot mix needs heat (300°F+). Cold mix works at air temp. Hot mix cures fast but costs $100-$200 per ton. Cold mix runs $50-$80 per ton. No gear needed for cold mix. Just pour, pack, and go.

Good and Bad for Big Lots

| Cold Mix | Hot Mix |

|---|---|

| Fix holes same day | Lasts 10-15 years |

| Works in rain/snow | Needs dry, warm days |

| Fades in 2-5 years | Resists heavy trucks |

Cold Mix Asphalt Vs. Concrete Surfaces

Concrete costs $8-$12 per sq ft. Cold mix costs $3-$5 per sq ft. Concrete lasts 20+ years but cracks in freeze zones. Cold mix bends with ground shifts. Need to fix concrete? Shut the lot for weeks. Cold mix patches dry in hours.

Cold Mix Vs. Chip Seal for Lots

Chip seal sprays tar, then gravel. Cheap ($2-$3 per sq ft) but messy. Stones fly up, scratch cars. Cold mix bonds tight—no loose bits. Chip seal lasts 3-7 years. Cold mix holds 2-5 years but fixes faster. Best for spots with light cars.

Now, let’s dig into specs: how thick to pour, what rocks to use, and how to store it right.

Technical Specifications for Parking Lots

Cold mix asphalt for commercial parking lots requires precise engineering to handle heavy vehicles while maintaining surface integrity. Proper specs ensure longevity under constant use.

Recommended Thickness Guidelines

Parking lot thickness depends on traffic volume. Commercial lots serving trucks or frequent traffic need stronger bases. Cold mix layers must balance load distribution with material efficiency.

Ideal Thickness for Commercial Traffic Loads

For light-duty lots (cars only), compact cold mix layers between 1.5-2 inches work. Medium-duty sites (delivery vans) require 2.5-3 inches. Heavy truck zones need 3.5-4 inches. Base layers of crushed stone (6-8 inches) boost stability.

Aggregate and Binder Requirements

Commercial-grade cold mix uses 3/8-inch crushed stone or RAP (recycled asphalt pavement) at 15-30% content. Binders like CSS-1h emulsion or MC-30 cutback provide cohesion. PG 64-22 binders improve cold-weather performance.

Storage and Application Temperature Ranges

Cold mix stays workable between 50°F-85°F without heating. Stockpile stored material below 90°F to prevent binder separation. Compact within 20 minutes of placement for optimal density (92-95% Proctor).

Proper specs set the foundation for lasting performance. Next, let’s break down how these factors influence installation methods.

Installation and Cost Factors

Cold mix asphalt for commercial parking lots offers fast installation with minimal equipment. Its flexibility makes it ideal for projects needing quick turnaround or off-season work.

Preparation and Layering Process

Start by cleaning the surface: remove debris, fill deep cracks with gravel, and apply a tack coat if bonding to existing pavement. Spread cold mix asphalt in 2-inch layers using graders or box spreaders. Compact each layer with a vibratory roller (3,000–5,000 PSI) to achieve 92–95% density. Unlike hot mix, cold asphalt mix packs require no heating—just ambient temperatures above 40°F for proper adhesion.

Cost Per Square Foot for Parking Lot Projects

Cold mix asphalt for commercial parking lots averages $1.50–$3.00 per square foot installed. Costs depend on layer thickness (3–4 inches recommended for heavy traffic), base repairs, and labor rates. Projects using recycled cold asphalt mix for parking lots save 15–20% on material expenses. Hot mix alternatives run 30–50% higher due to energy-intensive production.

Maintenance and Sealing Best Practices

Seal cold mix asphalt parking lots 6–12 months after installation using coal tar or asphalt-based sealants. Reapply every 2–3 years to prevent oxidation and water infiltration. Inspect for cracks wider than ¼ inch—fill with cold mix patching material. For high-traffic zones, plan annual surface evaluations to address wear patterns early.

With proper care, cold mix asphalt for commercial parking lots balances affordability and performance. Next, let’s examine how its environmental impact compares to traditional paving methods.

Environmental Considerations

Cold mix asphalt for commercial parking lots offers eco-friendly advantages beyond immediate repairs. Property managers gain sustainability benefits that align with modern construction standards while maintaining functional surfaces.

Use Of Recycled Materials

Cold mix asphalt for parking lots often contains 30-60% recycled asphalt pavement (RAP). This repurposes existing materials instead of sending them to landfills. The National Asphalt Pavement Association reports over 90 million tons of asphalt get recycled yearly in the U.S. By integrating RAP into cold mix formulas, projects cut demand for virgin aggregates and bitumen. This reduces mining needs and landfill contributions. Commercial sites using cold mix with high RAP content may qualify for LEED credits due to lowered resource extraction impacts.

Reduced Energy Consumption

Producing cold mix asphalt for commercial parking lots requires no high-temperature heating. Unlike hot mix asphalt (300-350°F production temps), cold mix binds aggregates at ambient temperatures. This slashes energy use by 50-60% per ton. Lower fuel consumption during manufacturing cuts CO₂ emissions by 20-30% compared to hot mix. For large parking areas exceeding 10,000 sq ft, this energy efficiency supports corporate sustainability targets without compromising installation timelines.

Balancing eco-performance with practicality makes cold mix asphalt for hard surfaces a strategic choice. Next, let’s address common queries about optimizing this material for high-traffic commercial zones.

Frequently Asked Questions

What Type Of Asphalt is Best for Commercial Parking Lots?

The best type of asphalt for commercial parking lots depends on specific project requirements, including traffic volume, climate, and budget. Cold mix asphalt is excellent for temporary fixes, while hot mix asphalt is ideal for long-term durability. Consider the intended use and environmental factors when selecting the right type.

How Thick Should Cold Mix Asphalt Be for Parking Lots?

The recommended thickness for cold mix asphalt in parking lots varies based on traffic loads. For light-duty areas (cars only), a thickness of 1.5-2 inches is suitable, whereas medium-duty sites require 2.5-3 inches. Heavy traffic zones should use a thickness of 3.5-4 inches for optimal performance.

What Are the Key Specifications for Cold Mix Asphalt?

Key specifications for cold mix asphalt include the use of 3/8-inch crushed stone, binder requirements such as CSS-1h emulsion or MC-30 cutback, and maintaining ambient temperatures between 50°F-85°F during application. Proper compaction and layering techniques also play a vital role in achieving desired density and longevity.

What Are the Drawbacks Of Cold Mix Asphalt?

One of the primary drawbacks of cold mix asphalt is its lower durability compared to hot mix asphalt, typically lasting only 1-3 years under average conditions. It may also be susceptible to rutting under heavy truck traffic, making it less suitable for high-load areas without proper enhancements like polymer modification. Regular maintenance is necessary to extend its life.

Closing Thoughts

Cold mix asphalt stands out as a practical choice for commercial parking lots. Its cost-effectiveness and all-weather application make it ideal for quick repairs and temporary solutions. While it offers a speedy installation process and lessens downtime, some limitations in durability should be considered. When properly applied, cold mix can effectively manage the daily demands of commercial traffic.

Whether opting for cold mix over hot mix or exploring its alternatives like concrete or chip seal, understanding its specifications is crucial for successful implementation. For accurate calculations and further information, check out Asphalt Calculator USA. Your next parking lot project could see substantial improvements with the right asphalt solution!

Additional Resources for You:

- Lavin, P. (2003). Asphalt Pavements: A Practical Guide to Design, Production, and Maintenance for Engineers and Architects. London: Taylor & Francis.

- What are hot mix and cold mix asphalt? – A1 Professional Asphalt & Sealing, LLC

- Cold Mix Asphalt | All States Materials Group

- Cold Mix Asphalt – Barrett Paving

- Pros and Cons of Asphalt and Concrete for Commercial Parking Lots – A1 Professional Asphalt & Sealing, LLC