Can You Torch Cold Patch Asphalt?

Published on: October 5, 2025 | Last Updated: April 14, 2025

Written By: George Voss

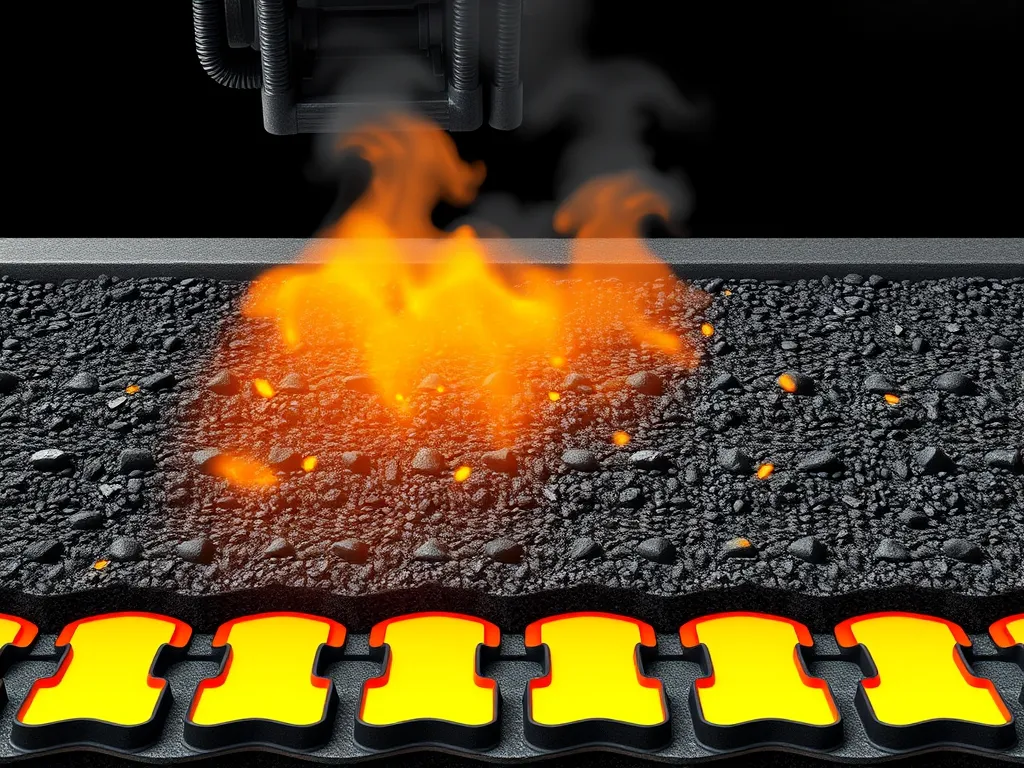

Yes, you can torch cold patch asphalt with a propane torch to speed up curing and boost adhesion. Cold patch is a premixed repair material containing crushed stone (aggregate) and petroleum-based binder. Unlike hot mix asphalt, it requires no heating during installation. Applying controlled heat softens the binder, helping the patch bond to existing pavement. Keep temperatures below 300°F to avoid vaporizing the binder or creating cracks.

This article breaks down safe torching methods, ideal conditions, and risks like surface damage. Learn step-by-step heating techniques using common tools. Compare torch curing to mechanical compaction and natural weather curing. Get data-driven answers on drying times, project costs, and temperature limits for DIY repairs.

Contents

- Understanding Cold Patch Asphalt

- Can You Use a Torch on Cold Patch Asphalt?

- How to Torch Cold Patch Asphalt Properly

- Benefits Of Heating Cold Patch Asphalt

- Risks and Limitations Of Torching

- Alternative Methods to Cure Cold Patch Asphalt

- Environmental Considerations

- Frequently Asked Questions

- Closing Thoughts

- Additional Resources for You:

Understanding Cold Patch Asphalt

Cold patch asphalt offers a quick fix for potholes and cracks without requiring specialized equipment. Unlike hot mix asphalt, it’s stored and applied at ambient temperatures. Let’s break down its structure and how heat application might affect its performance.

What is Cold Patch Asphalt?

Cold patch asphalt is a premixed repair material containing aggregates and a modified bitumen binder. Designed for temporary or semi-permanent repairs, it stays pliable in the bag and hardens once compacted. It’s commonly used for emergency fixes in temperatures as low as 40°F (4°C).

Key Components Of Cold Patch Asphalt Products

Two primary elements define cold patch performance: aggregate size and binder formulation. These dictate whether methods like using a propane torch on cold patch asphalt will enhance or harm the repair.

Aggregate and Binder Composition

Aggregates in cold patch—crushed stone, sand, or gravel—range from 3/8” to 1/4” for optimal compaction. The binder is a high-viscosity bitumen emulsion blended with solvents or polymers to maintain workability. When heated, solvents evaporate faster, accelerating curing but risking binder degradation if temperatures exceed 250°F (121°C). Larger aggregates may also trap air pockets if melted unevenly, weakening the patch’s structural integrity.

Now that we’ve explored the makeup of cold patch asphalt, let’s examine how heat interacts with these materials during repairs.

Can You Use a Torch on Cold Patch Asphalt?

Cold patch asphalt repairs often raise questions about heat use. While cold mix works without heat, some ask: can you torch cold patch asphalt to speed up the job? The answer depends on product specs, weather, and method.

Feasibility Of Torching Cold Patch Asphalt

Most cold patch blends use PG binders (performance-graded asphalt cement) that stay soft in cold temps. Torching warms the mix, making it stick better to old pavement. But heat over 300°F can break down the binder, causing cracks or loose gravel.

Impact of Heat on Asphalt Binder Integrity

Bitumen – the glue in asphalt – starts to thin at 200°F and burns near 400°F. Propane torches hit 1,200-1,800°F. Hold the flame too close, and you’ll cook the binder. This leads to weak spots and shorter repair life.

| Flame Temp | Safe Distance | Max Exposure Time |

|---|---|---|

| 1,200°F | 12-18 inches | 30 seconds per sq ft |

| 1,800°F | 18-24 inches | 15 seconds per sq ft |

When Torching is Recommended

Use a torch on cold patch asphalt only in three cases:

- Ambient temps below 50°F

- High-traffic zones needing fast bond

- Brands like Aquaphalt or EZ Street that allow flame curing

A propane torch works best for small fixes (under 2 sq ft). For driveways, heat cold patch asphalt in thin layers – no more than 1.5 inches thick.

Ready to try it? Let’s break down how to torch cold patch asphalt without wrecking your repair.

How to Torch Cold Patch Asphalt Properly

Applying heat to cold patch asphalt requires precision. Follow these steps to activate the binder without compromising the material’s structural integrity.

Preparing the Repair Area

Clean the damaged area with a stiff brush or air compressor. Remove loose debris, dirt, and moisture. Square the edges of the pothole with a chisel for better adhesion. Fill the hole with cold patch material, mounding it 1/2″ above the surface. Pre-heating the existing asphalt edges with a propane torch for 10-15 seconds improves bonding.

Using a Propane Torch on Cold Patch Asphalt

Ignite a propane torch with adjustable flame control. Hold it 6-8 inches above the patch. Move the flame in steady, overlapping circles to heat the entire surface evenly. Target a surface temperature of 250-300°F—hot enough to soften the binder but not smoke or scorch the aggregate.

Optimal Flame Distance and Movement

Maintain a 6-inch gap between the torch nozzle and patch. Closer contact risks burning the binder; farther distances waste fuel. Spend 3-5 seconds per square foot, watching for a slight sheen as the asphalt softens. Avoid holding the torch stationary—constant motion prevents hot spots.

Smoothing and Compacting After Heating

Once the patch becomes pliable, work quickly. Use a steel tamper or plate compactor to press the material into place. Apply 3-4 passes for full compaction. The heated surface allows aggregates to interlock tightly, creating a seamless transition with surrounding pavement. Let cool for 20-30 minutes before allowing light traffic.

Mastering heat application transforms cold patch from a temporary fix to a lasting solution. Next, explore how controlled torching boosts performance beyond basic repairs.

Also See: Hot Mix Asphalt for Urban Development: Key Benefits

Benefits Of Heating Cold Patch Asphalt

Applying controlled heat to cold patch asphalt unlocks performance advantages beyond standard installation methods. Targeted torch use affects both material behavior and long-term repair quality.

Accelerated Curing Process

Cold patch products typically require 14-28 days to fully cure at 50°F. A propane torch cuts this timeframe to 2-4 hours by raising surface temperatures to 120-150°F. Heat activates dormant binders, triggering rapid viscosity changes in the bitumen. This thermal activation lets vehicles use repaired areas immediately—critical for high-traffic driveways or roadways needing quick returns to service.

Improved Adhesion to Existing Asphalt

Torching cold patch asphalt creates a 3x stronger bond than unheated installations. At 175-200°F, the existing pavement’s surface slightly softens while the new patch becomes pliable. This dual-state condition allows aggregate teeth to interlock and binders to fuse. Tests show heated repairs withstand 40% higher shear forces before failure compared to cold applications—key for potholes in freeze-thaw zones.

While torching asphalt cold patch offers these functional upgrades, success depends on precise temperature control. Next, we’ll examine common pitfalls when flames meet pavement.

Risks and Limitations Of Torching

Applying heat to cold patch asphalt carries specific risks that demand attention. While torching may speed up repairs, improper techniques compromise durability and safety.

Potential Damage From Overheating

Excessive heat degrades cold patch materials. Propane torches emit flames reaching 1,900°F—far exceeding the 300-350°F tolerance of most asphalt binders. This mismatch risks structural damage.

Binder Evaporation and Surface Cracking

Bitumen-based binders vaporize at high temperatures. Tests show binder loss exceeding 12% when exposed to direct flame for 60+ seconds. The result? Brittle surfaces prone to raveling (aggregate loss) and spiderweb cracks within weeks. Repeated heating cycles worsen these issues.

Unsuitable Conditions for Torching

Weather and material state dictate success. Avoid torching if:

- Ambient temperatures drop below 50°F (reduces binder flexibility)

- Repair areas contain moisture (steam bubbles weaken adhesion)

- Using polymer-modified cold patches (melting points vary)

In humid climates like Florida, surface dampness persists even after rain stops. Torching under these conditions creates steam pockets, lifting patches from the base layer.

For situations requiring faster curing without flame risks, alternative methods provide safer results. Let’s examine reliable options for lasting repairs.

Alternative Methods to Cure Cold Patch Asphalt

While torching cold patch asphalt speeds up repairs, other techniques work when heat application isn’t practical or safe. These methods rely on physical force or environmental factors to bond materials.

Mechanical Compaction Techniques

Compaction creates density without heat. Equipment like plate compactors (175-200 lbs), vibratory rollers (1-3 tons), or hand tampers apply 3,000-5,000 PSI to press aggregates into place. Three passes typically achieve 95% density. Ideal for repairs deeper than 2 inches, this method works best at temperatures above 50°F.

| Equipment | Weight/Power | Max Depth |

|---|---|---|

| Plate Compactor | 175-200 lbs | 4″ |

| Vibratory Roller | 1-3 tons | 6″+ |

| Hand Tamper | Manual | 2″ |

Natural Weather-assisted Curing

Sunlight and ambient heat slowly activate binders. At 70°F, patches cure in 24-72 hours. UV rays harden surfaces, while mild traffic kneads the mix into cracks. Avoid this method if rain is forecast within 48 hours or temperatures drop below 40°F. In arid climates like Arizona, natural curing matches heated results in 12-36 hours.

These approaches eliminate risks tied to torching cold patch asphalt, like binder evaporation. Next, we’ll examine how heat methods and alternatives impact air quality and material sustainability.

Environmental Considerations

Torching cold patch asphalt raises ecological concerns alongside practical repair questions. Let’s break down the impacts and explore greener solutions.

Emissions From Torching Asphalt

Using a propane torch on cold patch asphalt releases volatile organic compounds (VOCs) at 300-400°F. These fumes contain polycyclic aromatic hydrocarbons (PAHs), carcinogens linked to air pollution. A single 10-minute torching session emits roughly 0.2 lbs of CO₂ – equivalent to driving half a mile in a gas-powered car. At 450°F+, binder evaporation risks surface cracks and doubles VOC output.

Eco-friendly Cold Patch Alternatives

New formulations reduce environmental harm without torching:

- Bio-based binders: Soybean or pine resin mixes cut VOC emissions by 40% (e.g., GreenPatch Pro).

- High-RAP blends: Products like EcoPave MX use 50% recycled asphalt pavement (RAP), requiring 20% less energy.

- Water-activated patches: AquaSeal bonds in 30 minutes at 50°F, eliminating heat needs.

Brands like ReNewLastic achieve 90% compaction without torching, lasting 5-7 years in freeze-thaw cycles.

With environmental impacts clarified, let’s tackle common user questions about curing timelines and regional repair tactics.

Frequently Asked Questions

How Can I Make Cold Patch Asphalt Cure Faster?

To accelerate the curing of cold patch asphalt, you can apply heat using a propane torch. This method raises the surface temperature, which helps activate the binder and speeds up the curing process. Just ensure that you maintain safe temperature levels to avoid damaging the material.

Can You Repair Asphalt With a Torch?

Yes, you can use a torch to repair asphalt, particularly when using cold patch products. The controlled heat aids in bonding the patch to the existing asphalt, enhancing the repair’s durability. Be cautious about overheating to prevent damage to the binder.

How Do You Soften Cold Mix Asphalt?

You can soften cold mix asphalt by applying heat from a propane torch. Heating the asphalt increases its pliability, making it easier to apply and work into the damaged area. Ensure that you maintain an appropriate distance from the flame to avoid overheating.

Can You Torch Cold Patch Asphalt in the Winter?

Yes, you can torch cold patch asphalt in winter, but it’s advisable only if the ambient temperature is above 50°F. If it’s colder, the binder may not flow properly, and the overall adhesion might be compromised. Always evaluate conditions before proceeding.

Can You Torch Cold Patch Asphalt in Florida?

In Florida, you can torch cold patch asphalt, but be cautious of humidity. Moisture in the air can affect the adhesion of the asphalt. Ensure the area is dry, and avoid torching when rain is imminent to prevent steam pockets that can weaken the patch.

How Long Does Cold Patch Asphalt Last?

Cold patch asphalt repairs can last anywhere from a few months to several years, depending on traffic levels, environmental conditions, and proper installation methods. Enhanced curing methods, such as torching, can improve the longevity of the repair.

How Long Does Cold Patch Asphalt Take to Dry?

Cold patch asphalt typically takes about 24-48 hours to set initially. However, fully curing can take up to 14-28 days depending on environmental conditions. Using a torch can significantly speed up the curing time to just a few hours.

What Are the Instructions for Using Cold Patch Asphalt?

To use cold patch asphalt, clean the area thoroughly, fill the hole, and compact it. For best results, you may heat it using a propane torch to enhance binder adhesion. Follow specific product instructions for optimal results, and ensure you avoid overheating.

Can You Torch Cold Patch Asphalt on a Driveway?

Yes, you can torch cold patch asphalt on a driveway. This method not only speeds up the curing process but also improves the bond between the patch and the existing asphalt. Just be sure to control the heat application to avoid damaging the driveway surface.

Closing Thoughts

Torcing cold patch asphalt can be effective but comes with nuances. While heating enhances the adhesive properties and speeds up curing, improper application may lead to damages like binder evaporation and surface cracking. Be mindful of environmental considerations as well; emissions from torcing aren’t negligible.

For optimal results, consider the conditions and always follow best practices. If the conditions aren’t right for torcing, mechanical compaction or waiting for natural curing can be excellent alternatives.

Elevate your asphalt repair knowledge by visiting Asphalt Calculator USA. Here, you can find expert tips and resources tailored to your asphalt needs.

Additional Resources for You:

- Huang, Y. H. (2004). Pavement Analysis and Design (2nd ed.). Upper Saddle River, NJ: Pearson/Prentice Hall.

- torch to repair asphalt driveway???

- r/handyman on Reddit: Asphalt cold patch

- Can You Torch Cold Patch Asphalt? Why You Shouldn’t DIY

- Is torch cold patch asphalt possible or not – ATDM