Can You Ground on Asphalt? Exploring Conductivity, Safety, and Best Practices

Published on: October 2, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Grounding on asphalt requires special techniques because standard asphalt isn’t naturally conductive. Made from crushed stone (aggregates) and bitumen binder, asphalt typically blocks electrical flow with resistivity values exceeding 1×10^12 ohm-meters. To ground effectively, you’ll need tools like copper grounding rods driven through the asphalt into soil or conductive mats bonded to buried electrodes. Safety depends on proper installation and testing conductivity levels.

This article explains how grounding works on asphalt surfaces. You’ll learn why composition and moisture impact conductivity, how to install grounding systems correctly, and how asphalt compares to concrete or gravel. We’ll cover static electricity risks, equipment choices (grounding mats vs. rods), and safety checks using multimeters. Whether you’re working on a driveway or parking lot, these insights ensure safe electrical connections.

Contents

What is Grounding?

Grounding links power systems to the earth. It keeps people safe when faults occur. This process sends stray power down to the soil. It stops shocks and shields gear from harm.

Principles Of Power Grounding

Grounding works by making a path for stray power. Parts like rods or plates in the soil send current down. These parts must have low resistance (under 25 ohms per NEC rules). Wires bond metal parts to stop spark risks. Proper setup keeps voltage levels safe during faults.

Importance Of Proper Grounding

Faulty grounding can lead to fires or broken gear. On asphalt, which blocks current flow, risks rise. Dry asphalt has high resistance (over 1,000 ohm-meters). Moisture or salt can lower it. Use ground mats or wires to beat these limits. OSHA codes demand checks to meet safety norms.

But does asphalt work for grounding? Let’s look at how it handles power flow.

Can You Ground on Asphalt?

Grounding requires direct contact with the earth’s electrons through conductive surfaces. Asphalt’s ability to transfer this energy depends on its electrical properties—a mix of science and material behavior.

Asphalt Conductivity Explained

Asphalt acts as an insulator under dry conditions. Its primary components—aggregates (crushed stone, sand) and bitumen binder—have high electrical resistivity (1×1012 Ω·m). This limits electron flow. Moisture or additives like carbon-rich materials can temporarily boost conductivity by up to 60% in wet scenarios.

Factors Affecting Grounding on Asphalt

Three variables determine asphalt’s grounding potential: moisture levels, material mix, and surface wear.

Moisture and Asphalt Composition

Water reduces resistivity by creating pathways for electrons. Polymer-modified asphalt (common in PG 64-22 binders) resists water better than standard mixes. Sealcoated surfaces block moisture absorption, lowering conductivity gains.

Age and Condition of Asphalt Surfaces

Cracked or weathered asphalt allows water infiltration, improving grounding capacity. Aged surfaces with 5+ years of wear show 30% lower resistivity than new pavements. Potholes or exposed aggregate further enhance electron transfer.

Asphalt Vs. Other Common Grounding Surfaces

Compare asphalt’s grounding performance to alternatives:

| Surface | Resistivity (Ω·m) | Grounding Efficiency |

|---|---|---|

| Dry Asphalt | 1×1012 | Low |

| Wet Asphalt | 1×106 | Moderate |

| Concrete (with rebar) | 1×103 | High |

| Grass (damp) | 1×102 | Very High |

| Gravel | 1×109 | Low |

Rebar-reinforced concrete outperforms asphalt due to embedded steel. Natural surfaces like grass provide optimal grounding. For asphalt driveways or blacktops, adding a grounding wire (6 AWG copper) bridges the conductivity gap.

Selecting the right surface is step one—next, learn how tools like asphalt grounding mats ensure reliable connections in any condition.

Grounding on Different Surfaces

Grounding works best on surfaces that allow strong contact with soil or carry natural conductivity. Asphalt’s insulating traits make it tricky, but other common paving materials vary in performance.

Grounding on Asphalt Driveways

Dry asphalt driveways typically show high resistance (1,000+ ohms) due to bitumen’s non-conductive nature. Moisture can lower this to 100-500 ohms. For reliable asphalt grounding, install a copper wire grid or mat linking to a soil rod. Without such tools, direct skin contact may not drain static fully.

Grounding on Concrete Surfaces

Concrete’s mix of sand, rock, and water grants modest conductivity. Its performance hinges on humidity levels and salt content. Additives like calcium chloride boost conduction by 30-50%.

Concrete Driveways

New concrete driveways (1-3 years old) often lack cracks for moisture absorption. Surface resistance ranges from 2,000-5,000 ohms. Sprinkling water or using a grounding mat with 25-ohm rating improves results.

Concrete Balconies

Upper-floor balconies lack direct soil contact. Bonding a grounding wire to structural rebar (if code-compliant) bridges this gap. Test with a multimeter to confirm paths below 100 ohms.

Concrete Basement Floors

Basements typically hold higher humidity, cutting resistance to 300-800 ohms. Barefoot grounding works here if floors lack vapor barriers or sealants. For painted surfaces, drill a 1/4” hole to insert a ground rod.

Grounding on Bricks and Pavers

Clay bricks and stone pavers absorb moisture, offering 1,500-3,000 ohms resistance. Gaps between units disrupt continuity. Lay a stainless-steel mesh under pavers or apply conductive gel (2-5 mm thick) to boost contact.

Grounding on Rocks and Gravel

Crushed stone or gravel beds act as insulators (10,000+ ohms) due to air pockets. Granite or limestone slabs may carry slight ionic conduction. For rocky yards, drive a 6-ft copper rod into soil below the gravel layer.

Surface choice impacts static discharge capacity, but asphalt’s insulation properties bring unique challenges. Up next: how weather and tools shape static risks on blacktop.

Also See: Commercial Vs Residential Asphalt Maintenance: Key Differences

Static Electricity and Asphalt

Static buildup poses unique challenges on asphalt surfaces. While not a primary conductor, asphalt’s properties influence static discharge risks during dry conditions or high-friction activities.

Does Asphalt Generate Static Electricity?

Asphalt can generate static electricity under specific conditions. Its composition—95% aggregates (stone, sand) bound by bitumen—creates an insulating surface with resistivity values between 10^12 and 10^15 ohm-meters. Dry asphalt lacks moisture to dissipate charges, allowing static buildup from foot traffic, vehicle movement, or equipment friction. For example, rubber-soled shoes sliding across asphalt may produce up to 5 kV of static charge.

Mitigating Static Risks on Asphalt

Reduce static hazards through three proven methods:

- Surface treatments: Apply antistatic coatings (carbon-based sprays) to lower resistivity below 10^9 ohm-meters

- Moisture management: Light misting increases conductivity—humidity above 60% minimizes charge retention

- Grounding systems: Install copper grounding wires (4 AWG minimum) beneath asphalt layers, connected to rods driven 8 ft into earth

Industrial sites often embed conductive grids during paving. ASTM D449-21 standards recommend testing surface resistivity monthly using four-point probe meters.

Ready to implement these solutions? The next section breaks down specialized tools for asphalt grounding systems.

Tools for Effective Grounding on Asphalt

While asphalt’s natural conductivity remains limited, specialized tools make safe grounding achievable. These systems bypass asphalt’s resistivity to establish reliable electrical paths.

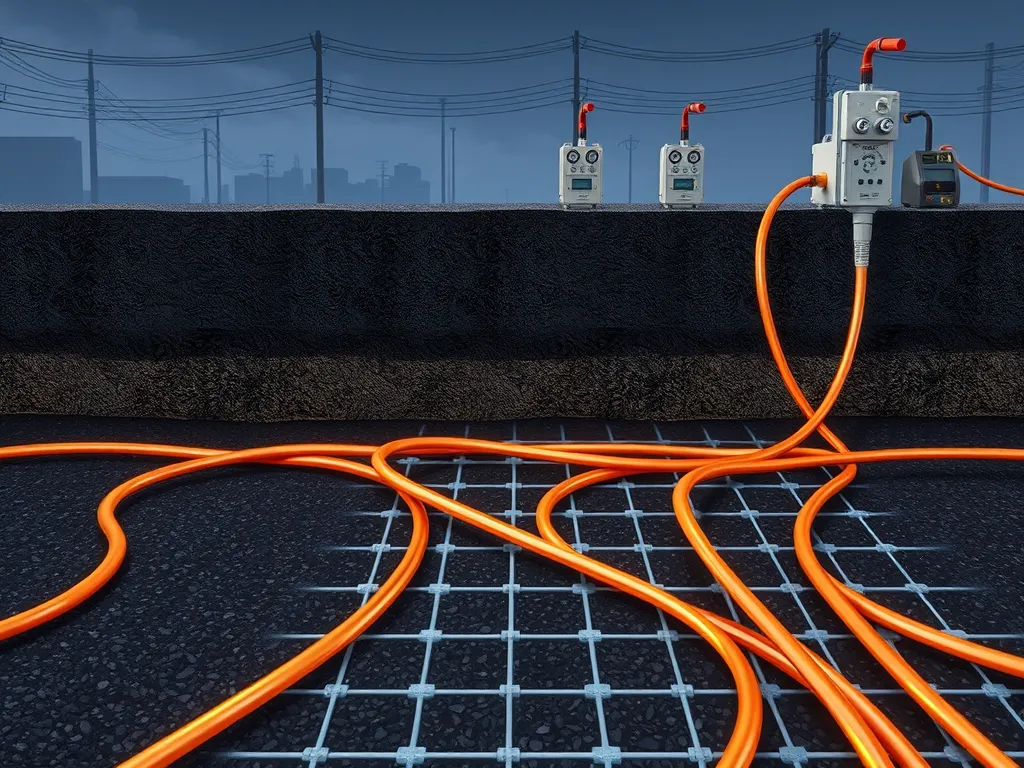

Asphalt Grounding Wires and Mats

Copper grounding wires (4-6 AWG) or galvanized steel mats create direct contact with earth beneath asphalt. NEC Article 250 requires buried conductors to handle fault currents up to 30kA. High-conductivity mats (0.5-1.5mm thick) with ≤5 ohm resistivity work best under parking lots or driveways. Costs range from $8-$15 per linear foot for wires or $100-$300 for prefabricated mats.

Installation Techniques for Grounding Systems

Installers first prepare asphalt surfaces by cleaning debris and cutting access points with diamond saws. Ground rods drive 8-10 feet into soil, spaced 6-8 feet apart. Conductive epoxy bonds wires to asphalt edges, while thermal welding joins mat sections. NEC mandates 18-inch burial depth for horizontal conductors under asphalt pavement. Bonding jumpers connect multiple rods to reduce ground potential rise.

Testing Conductivity on Asphalt Surfaces

Four-point Wenner testing measures soil resistivity beneath asphalt, targeting values below 25 ohms. Fluke 1625 or Megger DET4T2 meters verify system performance. Professionals test during dry spells when asphalt reaches 90°F+ to simulate worst-case scenarios. Annual checks detect corrosion or shifted pavements causing >10% resistance spikes.

Accurate testing ensures systems meet NFPA 70E safety standards for fault protection. Next, we examine weather risks and equipment handling to maintain secure operations.

Safety Considerations

Grounding systems on asphalt demand strict safety protocols. Environmental factors, equipment handling, and human error create risks requiring proactive management.

Weather Impacts on Asphalt Grounding

Rain increases asphalt’s conductivity by 15-30% due to moisture absorption. But standing water creates stray currents, raising shock risks. Dry summer heat above 90°F reduces conductivity by up to 40% as asphalt binder hardens. Winter freeze-thaw cycles cause cracks, disrupting electrical continuity. Thermal stress from temperature swings exceeding 50°F daily can warp grounding wire connections.

Handling Grounding Equipment Safely

Use UL-listed asphalt grounding wires rated for 600V minimum. Insulated copper-clad steel rods (3/8” diameter) penetrate asphalt 8-10 inches for stable contact. Wear dielectric gloves when testing systems with a megohmmeter. Check for exposed conductors yearly—frayed asphalt ground wires increase fault current risks by 70%.

Avoiding Common Grounding Mistakes

Never drive grounding rods through asphalt’s aggregate base—this weakens structural integrity. Test surface resistivity with a four-point tester (target: ≤10,000 Ω·m). Avoid using bare copper wires; asphalt’s sulfur content accelerates corrosion by 3x. Install galvanized steel grounding mats (4’x4’ grids) beneath high-traffic areas to distribute load evenly.

For specific scenarios, our FAQ section addresses concerns like static discharge rates on aged blacktop or code-compliant grounding wire blacktop installations.

Frequently Asked Questions (FAQs)

Can You Ground on an Asphalt Driveway?

Yes, grounding on an asphalt driveway is possible but requires additional tools. Since asphalt is generally non-conductive, using copper grounding wires or grounding mats can facilitate a proper ground connection.

Does Grounding Work on Concrete Driveways?

Yes, grounding is effective on concrete driveways due to their natural conductivity. Concrete can provide a better grounding path, especially when moisture is present.

Can You Ground on a Concrete Balcony?

Grounding on a concrete balcony can be achieved by bonding grounding wires to structural elements like rebar. This helps create a proper electrical connection back to the ground.

Is Grounding Effective on Bricks or Rocks?

Grounding on bricks or rocks can be challenging due to the potential for high resistance. To improve grounding, ensure that there is good contact between the grounding system and the underlying soil.

Can You Ground in a Concrete Basement?

Yes, grounding in a concrete basement can be effective. The typically higher humidity in basements can lower resistance, making grounding more efficient when appropriate methods are employed.

Does Asphalt Put Off Static Electricity?

Asphalt can generate static electricity under specific conditions, especially when dry. The insulating properties of asphalt can lead to static buildup from activities like foot traffic or vehicle movement.

Closing Thoughts

In conclusion, grounding on asphalt is a viable option, but it carries specific considerations. While asphalt surfaces can conduct electricity, various factors, such as moisture content and structural condition, significantly impact effectiveness. It’s vital to select proper tools and installation techniques to ensure safety and reliability.

When grounding on asphalt, always assess the surface carefully. Troubles with static electricity should not be overlooked, and precautions must be taken during installation. With the right approach, you can successfully utilize asphalt for grounding applications.

For detailed information on grounding techniques, materials, and calculations, be sure to visit our site: Asphalt Calculator USA.