Can Concrete Be Poured Over Asphalt?

Published on: October 2, 2025 | Last Updated: April 14, 2025

Written By: George Voss

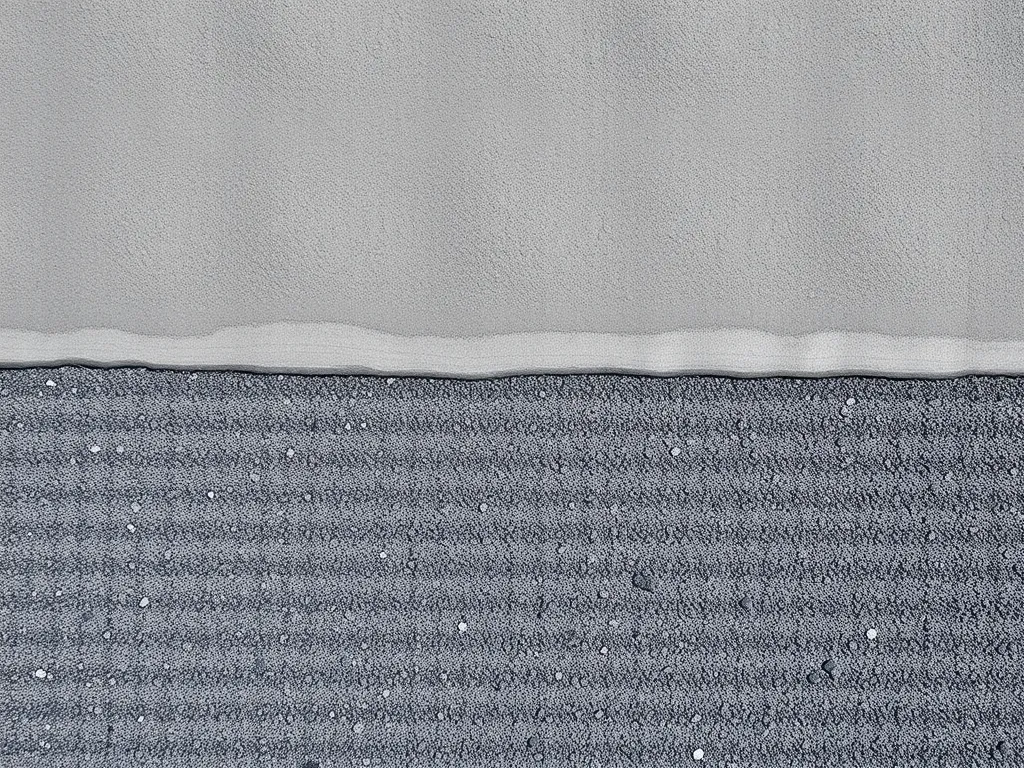

Yes, concrete can be poured over asphalt if the existing pavement is structurally sound and properly prepared. This method (called “white topping” in road projects) avoids costly asphalt removal but demands specific conditions: a stable base with no cracks or sinking, surface roughening through milling or grinding, and minimum concrete thickness of 4 inches for driveways. Pros include saving $3-$7 per square foot versus full replacement and gaining a durable surface. Cons involve potential cracking if the asphalt shifts or lacks proper drainage.

This article explains when pouring concrete over asphalt works – and when it fails. We cover how to test pavement stability, prep steps like cleaning oil stains or adding rebar, and cost differences between residential overlays vs commercial white topping. You’ll also learn critical details: required expansion joint spacing, bonding agent types like epoxy or latex, and why 6-inch concrete slabs outperform thinner pours on asphalt bases.

Contents

- Feasibility Of Pouring Concrete Over Asphalt

- Preparation and Installation Steps

- Pros and Cons Of Concrete Over Asphalt

- Thickness and Structural Requirements

- Cost Considerations

- Potential Issues and Solutions

- Environmental Impact Of Concrete Over Asphalt

- Frequently Asked Questions (FAQ)

- Closing Thoughts

- Additional Resources for You:

Feasibility Of Pouring Concrete Over Asphalt

Laying concrete over asphalt is possible but requires precise evaluation. The decision hinges on existing asphalt quality, structural needs, and environmental factors. Contractors often use this method for driveways, parking lots, or road rehabilitation to avoid full removal costs.

Is It Advisable to Pour Concrete Over Asphalt?

Proceed only if the asphalt base meets three criteria: minimal cracks (under ¼” wide), stable compaction (95%+ density), and proper drainage slope (2% minimum). Concrete overlays fail when applied over crumbling asphalt or areas with standing water. For high-traffic zones like commercial entries, consult engineers to verify load-bearing capacity.

Key Conditions for Successful Installation

Two non-negotiable factors determine overlay longevity: surface integrity of the asphalt and weather during installation. Ignoring either risks cracks, heaving, or bond failure within 12-24 months.

Asphalt Stability and Surface Integrity

Inspect the asphalt for alligator cracks, rutting, or oil stains. Repair defects with asphalt patching compounds or mill uneven sections. A 6-12″ gravel border around the perimeter prevents edge lifting. Test compaction using nuclear density gauges—subsidence over ⅛” under 300 PSI pressure indicates unstable bases.

Weather and Environmental Factors

Pour concrete when temperatures stay between 50°F-85°F. Cold climates demand air-entrained mixes (5-7% voids) to resist freeze-thaw damage. Avoid pouring if rain is forecast within 24 hours—premature moisture exposure weakens the slab’s 28-day compressive strength (target 3,500+ PSI). In humid regions, apply epoxy primers to limit vapor transmission from old asphalt.

Proper preparation sets the stage for installation. Next, we break down the step-by-step process to bond concrete securely to asphalt surfaces.

Preparation and Installation Steps

Laying concrete over asphalt demands precision. Proper groundwork determines whether the overlay lasts 20+ years or fails prematurely.

How to Prepare Asphalt for Concrete Pouring

Start with a stable base. Existing asphalt must withstand 3,000-4,000 PSI concrete loads without shifting.

Step 1: Clean and Repair Existing Asphalt

Pressure-wash the surface at 2,500-3,500 PSI to remove dirt, oil, and loose aggregate. Fill cracks wider than 1/8″ with asphalt emulsion patching compounds. For potholes, excavate damaged areas and compact fresh hot-mix asphalt to 95% density. Apply a tack coat (asphalt emulsion) to enhance adhesion if the surface is smooth.

Step 2: Ensure Proper Drainage and Leveling

Verify slope gradients using a laser level. Asphalt bases require a minimum 1/4″ per foot slope to prevent water pooling under the concrete. Use sand or gravel leveling courses to correct uneven areas exceeding 1/2″ over 10 feet. Install edge forms with 2×4 lumber to contain the pour.

Bonding Concrete to Asphalt

Adhesion prevents delamination. Asphalt’s flexible nature contrasts with concrete’s rigidity, requiring strategic bonding methods.

Techniques for Adhesion

Epoxy primers or latex-based bonding agents (applied at 200-300 sq ft per gallon) create a chemical bond. For thicker overlays (6″+), drill 12″ rebar dowels into the asphalt at 24″ intervals. Roughen smooth surfaces with a milling machine to increase mechanical grip.

Role of Wire Reinforcement

Welded wire mesh (6×6-W1.4xW1.4) or #3 rebar grids (18″ spacing) reduce cracking from thermal expansion. Elevate reinforcement 1.5″ using plastic chairs to center it within the concrete slab. This distributes loads evenly, counteracting minor asphalt movement.

With the base prepped and bonding strategy set, the next phase involves evaluating whether this hybrid system aligns with your project’s cost and durability goals.

Pros and Cons Of Concrete Over Asphalt

Choosing to pour concrete over asphalt requires weighing both benefits and risks. This decision affects project timelines, budgets, and structural performance for years.

Advantages Of Concrete Overlays

Concrete overlays offer unique benefits when installed over asphalt bases. These advantages make them popular for driveways, parking lots, and municipal road projects.

Enhanced Durability and Aesthetic Flexibility

Concrete lasts 25-40 years versus asphalt’s 15-20 year lifespan. It withstands freeze-thaw cycles better due to higher PSI strength (3,500-4,500 vs asphalt’s 1,500-3,000). Stamped patterns, exposed aggregates, or colored finishes let property owners customize surfaces without removing existing asphalt.

Long-Term Cost Efficiency

While upfront costs run $8-$15 per sq ft for concrete over asphalt, maintenance drops by 30-50% compared to asphalt-only surfaces. No need for annual sealcoating reduces labor and material expenses over time.

Challenges and Risks

Not every asphalt base works for concrete overlays. Hidden flaws in the original pavement can trigger costly failures.

Cracking and Maintenance Concerns

Concrete lacks flexibility, making it prone to reflective cracking if the asphalt base shifts. Temperature swings widen cracks by 0.25-0.5 inches annually without proper expansion joints. Polypropylene fibers or wire mesh reinforcement minimize but don’t eliminate this risk.

Impact of Asphalt Degradation

Asphalt breaks down at 0.1-0.3 inches per decade under concrete. Uneven settling creates voids that cause slab sinking—up to 1 inch every 5 years in poorly compacted bases. Geotechnical surveys using ground-penetrating radar help detect weak zones before pouring.

Structural demands vary based on load requirements. Let’s explore how thickness specifications differ for driveways versus heavy-traffic areas.

Also See: Benefits Of Using Infrared Heating for Asphalt

Thickness and Structural Requirements

Concrete thickness directly impacts performance when placed over asphalt. A minimum of 4 inches meets basic residential needs, while commercial projects demand 6-8 inches. Load capacity, freeze-thaw cycles, and asphalt base stability dictate exact measurements.

Recommended Concrete Thickness Over Asphalt

Use 4-inch slabs with 4000 PSI concrete for driveways or patios. Add wire mesh or #3 rebar at 18-inch spacing to minimize cracking. Thinner pours risk structural failure under vehicle weight or ground movement.

Residential vs. Commercial Applications

Homeowners often opt for 4-5 inches over stable asphalt bases. Commercial settings like parking lots require 6-8 inches of 5000 PSI concrete with doweled joints. Heavy truck traffic may necessitate geotextile fabric between layers for added support.

White Topping: A Specialized Approach

This method uses bonded or unbonded concrete overlays on asphalt pavements. Bonded white topping (4-6 inches) fuses to the asphalt via surface milling. Unbonded white topping (6-10 inches) acts as a separate layer, ideal for highways with 8000+ average daily traffic.

What Is White Topping for Asphalt?

White topping refers to Portland cement concrete overlays on existing asphalt surfaces. Milling creates a rough texture for mechanical bonding. The process extends pavement life by 15-20 years and cuts maintenance costs by 30% compared to full replacement.

Proper thickness and method selection affect both durability and budget. Next, let’s break down cost factors for concrete-over-asphalt projects.

Cost Considerations

When weighing options for paving, cost plays a big role. Let’s break down what you need to know about pricing when pouring concrete over asphalt.

Cost Comparison: Concrete Vs. Asphalt Overlays

Fresh asphalt costs $4-$8 per sq. ft., while concrete runs $8-$12 per sq. ft. But overlays change the math. Using old asphalt as a base can cut costs by 20-40% vs. full removal. For example, a 500 sq. ft. driveway with concrete overlay may cost $5,000-$7,000 vs. $8,000-$12,000 for full tear-out and new concrete.

Factors Affecting Total Expense

| Factor | Impact |

|---|---|

| Asphalt health | Cracked or soft spots add $1-$3/sq. ft. for repairs |

| Slope fixes | Drainage tweaks cost $2-$5/sq. ft. |

| Concrete type | Fiber-reinforced adds $0.50-$1.50/sq. ft. |

| Labor rates | Vary by $30-$80/hr based on location |

Is Pouring Concrete Over Asphalt Cheaper?

It can be. Skipping asphalt removal saves $3-$5/sq. ft. in demo fees. But if the base shifts or drains poorly, long-term fixes may offset savings. For light use (paths, patios), overlays often pay off. For heavy traffic (driveways, lots), check slab depth – 4” concrete over stable asphalt meets most codes.

Cost matters, but so does planning. Next, we’ll tackle how to avoid cracks and shifts in your project.

Potential Issues and Solutions

Pouring concrete over asphalt presents unique challenges requiring targeted solutions. Proper planning prevents common failures like cracks or uneven surfaces.

Preventing Concrete Cracking Over Asphalt

Concrete slabs crack when the asphalt base shifts or expands. Temperature changes cause asphalt to contract/expand up to 2x more than concrete. This differential movement creates stress points. Use these strategies:

Reinforcement and Expansion Joints

Steel rebar (#4 grade) or welded wire mesh (6×6 W1.4xW1.4) strengthens slabs. Place expansion joints every 8-12 feet using preformed cork/rubber strips. For driveways, install isolation joints where concrete meets structures. ASTM C150-compliant concrete mixes with 4,000+ PSI resist shear forces better.

Addressing Asphalt Movement and Settling

Asphalt settles 1/8″ annually under 4″ concrete. Inspect the base for voids using ground-penetrating radar or core samples. Repair cracks >1/4″ wide with asphalt emulsion patching. For unstable bases, apply a 2″ sand/gravel leveling course. In extreme cases, use bonded overlays with epoxy primers ($1.50-$3.50/sq.ft) or geotextile fabric to separate layers.

Next, we’ll explore how environmental factors influence these installations.

Environmental Impact Of Concrete Over Asphalt

Choosing between materials involves weighing ecological effects. Pouring concrete over asphalt presents unique environmental trade-offs tied to resource use, energy demands, and long-term sustainability.

Energy Efficiency and Sustainability

Concrete production emits 0.93 pounds of CO₂ per pound of cement—nearly double asphalt’s 0.48 pounds per ton. But overlays cut energy use by reusing existing asphalt bases. White topping, a specialized concrete overlay, leverages existing pavement strength while reducing new aggregate mining by 30-40%.

Concrete’s high albedo (reflectivity) lowers urban heat island effects. A typical concrete surface reflects 30-50% of sunlight versus asphalt’s 5-10%. This can reduce ambient temperatures by 2-4°F in paved areas. Modern mixes with 20% fly ash or slag (SCMs) lower embodied energy by 15% compared to traditional Portland cement.

| Material | CO₂ Emissions (per ton) | Recycled Content Potential |

|---|---|---|

| Concrete | 410 lbs | Up to 35% |

| Asphalt | 380 lbs | 95%+ |

Recycling Considerations

Asphalt under concrete remains recyclable. Milling equipment can later separate materials, reclaiming 90% of asphalt for reuse in roads. Concrete itself can be crushed into aggregate for future projects—though bonded layers require extra processing.

Projects using 30% recycled concrete aggregate (RCA) save 6-8% in material costs. Permeable concrete overlays add ecological value by managing stormwater—reducing runoff by up to 80% compared to sealed asphalt surfaces.

These environmental factors influence practical choices for driveways, parking lots, and roads. Let’s address common questions about combining asphalt and concrete.

Frequently Asked Questions (FAQ)

Can I Pour Concrete Over an Existing Asphalt Driveway?

Yes, you can pour concrete over an existing asphalt driveway as long as the asphalt is in good condition, properly prepared, and meets structural requirements.

How Thick Should Concrete Be Over Asphalt?

The recommended thickness for concrete over asphalt typically ranges from 4 to 6 inches, depending on the application and expected load. Residential driveways usually require 4 inches, while commercial applications may need thicker slabs.

Can Self-leveling Concrete Be Used on Asphalt?

Self-leveling concrete can be used on asphalt, but proper surface preparation is essential to ensure adequate bonding and performance.

Is Bonding Concrete to Asphalt Durable?

Yes, if proper bonding techniques and materials are employed, bonding concrete to asphalt can result in a durable and long-lasting surface. The key is ensuring the asphalt is stable and properly prepared.

Can Asphalt Sealer Be Applied Over Concrete?

Yes, asphalt sealer can be applied over concrete, but it is more common to use sealers specifically designed for concrete surfaces to ensure compatibility and longevity.

Closing Thoughts

Pouring concrete over asphalt is a viable option when approached with care. Ensure the asphalt is stable and well-prepared before installation. By following the necessary steps and understanding the pros and cons, you can achieve a durable and aesthetically pleasing surface.

Consider concrete overlays for their long-term benefits, but weigh potential risks such as cracking and maintenance needs. Understanding these factors is crucial for making an informed decision.

For more detailed information and resources, visit Asphalt Calculator USA. Your journey to a successful project starts here!

Additional Resources for You:

- Transportation Research Board (TRB, Peer-Reviewed Research & Circulars)

- Can Concrete Be Poured Over Asphalt? Pros, Cons and Considerations

- Installing concrete over asphalt

- Why Paving Concrete Over Asphalt is Only a Temporary Solution

- Shop Management and Owner Issues | concrete over asphalt for machine shop | Practical Machinist – Largest Manufacturing Technology Forum on the Web