Bitumen Storage and Handling Techniques for Efficient Asphalt Production

Published on: October 1, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Bitumen storage and handling techniques ensure this vital asphalt binder stays usable from tank to pavement. These methods combine heated storage tanks, precise temperature controls, and specialized pumps to maintain bitumen’s 300-350°F viscosity range. Proper handling prevents oxidation, preserves pavement performance, and meets OSHA safety standards for hot material operations.

This guide examines industrial storage solutions for asphalt plants, from horizontal tanks to modular systems. We’ll analyze heating methods like thermal fluid circulation, compare pumping technologies, and review contamination prevention tactics. Safety protocols, including PPE requirements and spill containment, are covered alongside environmental best practices for bitumen storage.

Contents

- Fundamentals Of Bitumen Storage for Asphalt Operations

- Bitumen Handling Techniques for Asphalt Manufacturing

- Critical Factors in Bitumen Storage Stability

- Bitumen Shelf Life in Pavement Context

- Safety in Bitumen Handling for Asphalt Facilities

- Environmental Management in Bitumen Storage

- FAQs: Bitumen Storage & Handling for Asphalt Professionals

- Closing Thoughts

- Additional Resources for You:

Fundamentals Of Bitumen Storage for Asphalt Operations

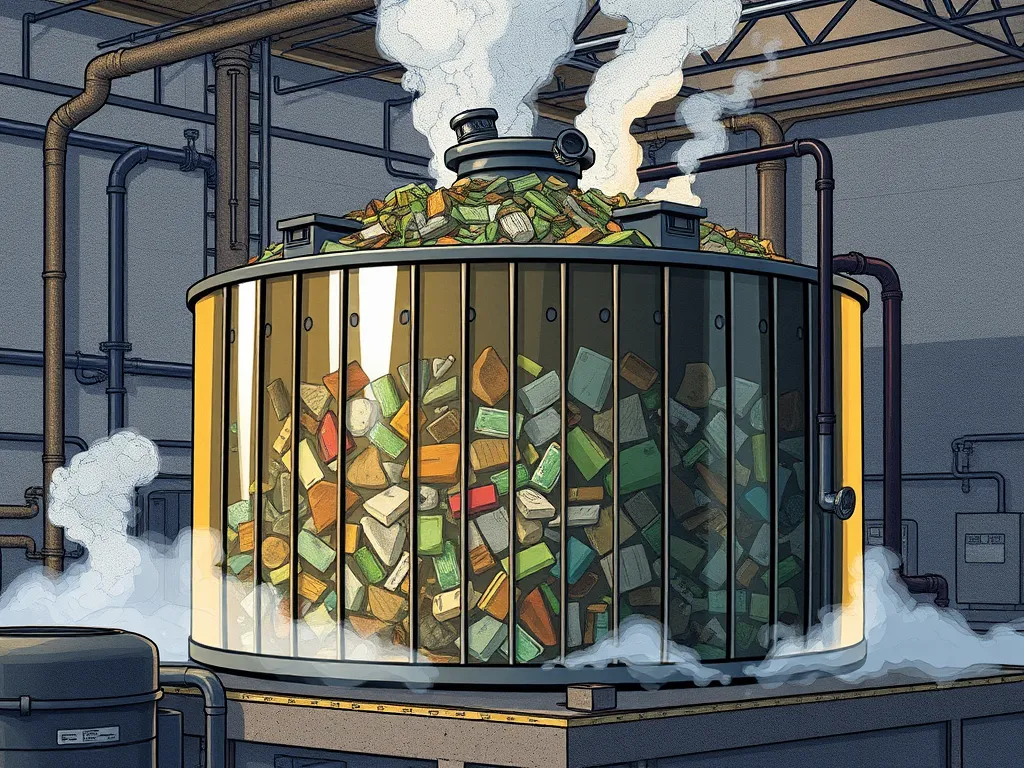

Effective bitumen storage methods form the backbone of asphalt production. Storage systems must maintain material integrity while enabling seamless integration with plant workflows.

Types Of Bitumen Storage Systems

Selecting the right storage infrastructure impacts efficiency, safety, and asphalt quality. Modern facilities use three primary designs.

Horizontal vs. Vertical Storage Tanks

Horizontal tanks (30-50 ft length) suit smaller asphalt plants with 5,000-20,000-gallon capacity needs. Vertical tanks (20-40 ft height) handle 50,000+ gallons for high-volume operations. Vertical designs reduce footprint but require specialized pumping systems.

Insulated and Modular Tank Designs

Double-walled tanks with 4-6″ mineral wool insulation cut heat loss by 70%. Modular systems allow rapid capacity expansion—critical for asphalt plants scaling production. These designs maintain temperatures within 15°F of target ranges.

Floating Roof Tank Applications

Floating roofs minimize air exposure in large (100,000+ gallon) storage operations. This asphalt storage technique reduces oxidation by 90% compared to fixed-roof tanks, preserving PG binder quality.

Temperature Management in Bitumen Storage

Precise thermal control prevents hardening and maintains workability. Even 20°F deviations can alter penetration grades by 15%.

Optimal Temperature Ranges for Asphalt-Grade Bitumen

PG 64-22 requires 275-325°F storage. Polymer-modified binders need 325-350°F. Temperatures above 375°F accelerate aging—monitor closely.

Heating Methods: Circulation Systems and Tank Heaters

Thermal oil circulation jackets provide even heating for vertical tanks. Horizontal tanks often use electric immersion heaters (50-150 kW). Fuel-fired tube heaters suit remote sites, maintaining 1-2°F/hour recovery rates.

Monitoring Tools: Thermocouples and Automated Controls

Type-K thermocouples track temperatures at 3+ tank zones. Automated systems adjust heating based on real-time viscosity readings—critical for handling techniques for bitumen during transfer.

Proper temperature control preserves material quality while setting the stage for efficient pumping and mixing operations. Next, we examine how these storage practices integrate with active asphalt production workflows.

Bitumen Handling Techniques for Asphalt Manufacturing

Proper handling methods ensure bitumen maintains its performance properties during asphalt production. From transfer systems to plant integration, precise protocols preserve material integrity while boosting operational efficiency.

Safe Transfer and Pumping Procedures

Moving hot bitumen between storage tanks and mixing units demands specialized equipment. Operators follow strict thermal management guidelines to prevent burns or material degradation during transfer.

Pre-Heating Protocols for Viscosity Control

Bitumen requires pre-heating to 150-170°C before pumping. Thermal oil jackets or electric tracing systems lower viscosity to 200-300 cP, enabling smooth flow. Exceeding 190°C risks thermal cracking, while under-heating strains pumps.

Pump Selection for Hot Bitumen Transfer

Gear pumps handle 5-200 m³/hour flows with discharge pressures up to 30 bar. Opt for models with steam-heated casings maintaining 160-180°C. Positive displacement variants work best for polymer-modified binders needing higher shear resistance.

Handling in Asphalt Plant Workflows

Bitumen enters production lines through precisely calibrated systems. Modern plants use automated controls to sync binder delivery with aggregate mixing cycles, ensuring consistent hot mix asphalt quality.

Integration with Mixing and Aggregate Systems

Batch plants meter bitumen via load cells (±0.5% accuracy), while drum mixers rely on mass flow meters. Systems maintain 160-175°C during blending with heated aggregates. Crossbelt sensors verify mix ratios meet Superpave specifications.

Contamination Prevention Strategies

Dedicated lines for different binder grades avoid cross-contamination. Install 100-mesh inline filters to trap particulates. Weekly tank bottom checks detect water ingress—limit moisture below 0.5% to prevent foaming in hot mix.

Effective bitumen management extends beyond handling—proper storage conditions directly influence pavement performance. Up next: maintaining material stability through advanced storage solutions.

Critical Factors in Bitumen Storage Stability

Bitumen storage stability directly affects asphalt pavement quality. Poor storage leads to material hardening, reduced adhesion, and compromised road durability. Proper techniques maintain chemical composition while preventing thermal degradation.

Impact on Asphalt Performance

Oxidized bitumen loses flexibility, causing premature pavement cracks under traffic loads. Stored at incorrect temperatures, the binder develops uneven viscosity. This creates mix inconsistencies during asphalt production. For PG binders (performance-graded asphalt binders), even minor quality drops reduce resistance to thermal stress and rutting.

Oxidation Prevention Techniques

Limit oxygen exposure through sealed storage tanks with vapor barriers. Operators control tank temperatures between 150-180°C to slow oxidation rates. Additives like anti-oxidant polymers (e.g., SBS modifiers) extend binder lifespan. Regular sampling verifies penetration grades stay within ASTM D946 specs.

Role of Nitrogen Blanketing and Agitation

Nitrogen blanketing displaces oxygen in tank vapor spaces, cutting oxidation by up to 70%. Combined with mechanical agitation, this method prevents bitumen stratification. Slow-speed agitators (3-5 RPM) maintain homogeneity without overheating. Facilities using these systems report 30% fewer asphalt mix failures due to binder issues.

Effective storage stability sets the stage for evaluating bitumen shelf life under varying conditions. Next, we examine how environmental factors and rotation cycles influence material longevity.

Also See: Evaluating the Cost-effectiveness Of Professional Vs DIY Asphalt Tools

Bitumen Shelf Life in Pavement Context

Maintaining binder quality during storage directly impacts pavement performance. Proper techniques preserve rheological properties needed for durable mixes.

Storage Duration Guidelines

Bulk bitumen typically remains viable for 6-12 months when stored between 275-325°F. Performance-Graded (PG) binders show reduced cracking resistance beyond 9 months due to oxidation. Thermal cycling beyond 50°F daily swings cuts effective shelf life by 30%.

Environmental Factors Affecting Longevity

Three elements degrade stored bitumen: temperature swings exceeding 20°F daily, moisture levels above 60% RH causing foaming, plus UV exposure breaking polymer bonds. Insulated tanks with nitrogen blanketing reduce oxidation rates below 0.5% monthly.

Rotation Practices for Bulk Storage

Implement FIFO protocols using circulation pumps every 90 days minimum. Facilities moving over 5,000 tons monthly benefit from split-tank designs enabling continuous turnover. Monitor viscosity changes – increases beyond 15% from baseline signal needed rotation.

Proper rotation sets the stage for exploring safety protocols required when managing hot binder systems.

Safety in Bitumen Handling for Asphalt Facilities

Bitumen handling techniques demand rigorous safety protocols due to extreme temperatures and material hazards. Asphalt facilities handling PG 64-22 or polymer-modified binders face unique risks requiring specialized protection and contingency plans.

PPE Requirements for Hot Material Handling

Workers require PPE rated for 300-350°F bitumen temperatures. Flame-resistant (FR) coveralls, aluminized gloves, and ASTM F2413-certified steel-toe boots form the base layer. Face shields with UV protection prevent splatter exposure during transfers. For tank entry, OSHA-compliant respirators with organic vapor cartridges mitigate fume inhalation risks.

Emergency Response Planning

Facilities storing over 1,000 gallons must implement spill containment per EPA 40 CFR 112. Secondary containment systems with 110% tank capacity prevent environmental breaches. Quarterly drills train teams on bitumen handling system failures, including pump seal leaks or heater malfunctions.

Spill Containment and Burn Management

Clay-based absorbents and thermal blankets tackle small spills. For major incidents, deploy skimmers and vacuum trucks to isolate bitumen from drains. Burn protocols prioritize immediate 20-minute cold water rinses (per ANSI Z358.1) – never ice or ointments. Medical-grade hydrogel dressings stocked onsite reduce tissue damage until EMTs arrive.

While safety protocols protect workers, environmental controls safeguard ecosystems. Next, we explore emission reduction strategies for bitumen storage operations.

Environmental Management in Bitumen Storage

Proper storage practices protect ecosystems while maintaining bitumen quality for asphalt production. Modern facilities blend containment systems with recycling protocols to meet sustainability goals without compromising pavement performance.

Emission Control From Storage Tanks

Bitumen vapors release volatile organic compounds (VOCs) when stored above 150°C. Three methods curb emissions:

- Vapor recovery units capture 95%+ of fumes using condensation or adsorption

- Floating roof tanks reduce vapor space by 80% compared to fixed-roof designs

- Closed-loop transfer systems prevent leaks during loading/unloading

Insulated tanks with automated temperature controls cut fuel use by 15-20%, indirectly lowering CO2 output. Regular inspections of seals, vents, and heating coils ensure compliance with EPA Tier IV standards.

Recycling Bitumen Waste in Asphalt Mixes

Leftover bitumen from tank cleaning or rejected batches gets new life in pavements. Mills blend 5-10% recycled bitumen with virgin PG 64-22 binder using:

- High-shear mixers to restore uniformity

- Rejuvenators like tall oil to replenish maltenes

- Infrared heaters for precise viscosity matching

Storing recycled material requires dedicated tanks kept at 135-140°C with weekly agitation. This process slashes raw material costs by $8-12 per ton while meeting AASHTO M 323 specs for recycled binder blends.

With eco-friendly systems in place, teams must next focus on protocols protecting workers from thermal risks during daily operations.

FAQs: Bitumen Storage & Handling for Asphalt Professionals

How Can Bitumen Be Stored Without Quality Loss?

To prevent quality loss during storage, ensure that bitumen is kept at optimal temperatures (generally between 275-325°F for standard grades) and in sealed, insulated tanks that minimize exposure to air. Using nitrogen blanketing can also help reduce oxidation, maintaining the integrity of the binder.

What Temperature Range Ensures Optimal Bitumen Storage?

Maintaining bitumen in the temperature range of 275-325°F is critical for standard asphalt-grade bitumen. For modified binders, temperatures can be higher, generally between 325-350°F. Consistent monitoring of these temperatures is essential to avoid quality degradation.

How Does Storage Stability Affect Asphalt Pavement?

Storage stability is crucial for asphalt pavement performance. If bitumen is oxidized or stored at incorrect temperatures, it may become brittle, leading to cracks and reduced adhesion in the final pavement. Proper storage techniques significantly reduce these risks, enhancing the overall durability of asphalt surfaces.

Is There a Shelf Life Limit for Stored Bitumen?

Yes, bitumen typically has a shelf life of 6-12 months, depending on storage conditions. Exposure to temperature fluctuations, moisture, and oxygen can compromise its performance over time. Therefore, regular monitoring and proper rotational practices are necessary to ensure its usability for asphalt production.

Closing Thoughts

Effective bitumen storage and handling techniques are vital for maintaining the quality of asphalt. Proper systems, such as insulated tanks and floating roof designs, paired with robust temperature management, ensure that bitumen stays within optimal ranges for asphalt production. Implementing safe transfer, pumping procedures, and contamination prevention strategies in workflows further enhances asphalt efficiency.

Remember, ensuring bitumen stability directly impacts the performance of asphalt pavements. Techniques like nitrogen blanketing and regular rotation practices help maintain quality and extend shelf life. Safety measures, including PPE and emergency response planning, are crucial for protecting personnel. Moreover, addressing environmental management by controlling emissions and recycling bitumen waste contributes to sustainable operations in asphalt facilities.

For more insights and tools related to asphalt production, visit Asphalt Calculator USA.

Additional Resources for You:

- Huang, Y. H. (2004). Pavement Analysis and Design (2nd ed.). Upper Saddle River, NJ: Pearson/Prentice Hall.

- Storage and Handling of Bitumen Emulsion | Infinity Galaxy

- Seven best practices for storing and handling asphalt emulsions – Asphalt magazine

- ASPHALT EMULSION STORAGE- Storage & Handling of asphalt emulsion

- How Do You Store Bitumen + Bitumen Storage | Nikan west gilsonite