Bitumen Softening Point Testing: Methods, Importance, and Standards in Asphalt Applications

Published on: September 27, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Bitumen softening point testing determines the temperature at which asphalt binders soften under controlled heat. This test uses a ring-and-ball apparatus to measure how bitumen deforms when heated – critical for predicting asphalt’s performance in hot climates. Following ASTM D36 or AASHTO T53 standards ensures accurate results. Labs use this data to verify binder grades like 60/70 bitumen, which typically softens between 46°C and 54°C (115°F–129°F).

This guide breaks down softening point testing for asphalt professionals. You’ll learn equipment setup for ring-and-ball tests, step-by-step heating protocols, and compliance with ISO 4625. We’ll explore how results impact pavement durability, mix designs for high-traffic roads, and quality control for common binder grades. Read on to master temperature susceptibility testing and avoid costly field failures.

Contents

- Introduction to Bitumen Softening Point Testing

- Importance Of Softening Point Testing in Asphalt

- Testing Methods and Equipment

- Softening Point Of 60/70 Bitumen in Asphalt Applications

- Softening Point Vs. Melting Point in Asphalt Context

- Troubleshooting and Best Practices

- Environmental Considerations in Softening Point Testing

- FAQs on Bitumen Softening Point Testing

- Closing Thoughts

- Useful References for You:

Introduction to Bitumen Softening Point Testing

Bitumen softening point testing measures the temperature at which asphalt binders transition from solid to semi-liquid states. This test, standardized by methods like ASTM D36 and AASHTO T53, evaluates heat tolerance – a critical factor for pavements exposed to high temperatures. Engineers rely on this data to predict how binders will perform under traffic loads during summer months.

Role Of Softening Point in Asphalt Performance

A higher softening point indicates better resistance to rutting at elevated temperatures. For example, 60/70 penetration grade bitumen typically has a softening point between 46°C and 54°C. If this value drops below 45°C, pavements in warm climates may deform under heavy trucks. Testing ensures binders meet regional requirements: desert areas demand grades above 50°C, while cooler zones tolerate 40-45°C ranges.

Key Definitions: Softening Point Vs. Asphalt Behavior

While the softening point measures bitumen’s heat response, asphalt behavior encompasses broader properties:

- Softening point: Exact temperature at which bitumen deforms under a 3.5g steel ball in water/glycerin baths

- Asphalt viscosity: Flow resistance during mixing/compaction at 135-165°C

- Elastic recovery: Ability to regain shape after stress

Softening point tests don’t assess cold-weather cracking but directly correlate to summer pavement stability. A binder with a 50°C softening point retains stiffness up to that threshold, while lower grades risk premature failure.

With these fundamentals established, let’s examine how softening point values shape decisions in asphalt mix design and binder specifications.

Importance Of Softening Point Testing in Asphalt

Softening point testing determines how bitumen behaves under rising temperatures. This metric directly affects pavement performance, construction methods, and long-term maintenance needs.

Temperature Susceptibility and Pavement Durability

Bitumen with low softening points (below 40°C) deform under summer heat, causing rutting. Materials exceeding 70°C may crack during winter due to brittleness. The test identifies the temperature range where binders transition from rigid to fluid states. For 60/70 grade bitumen, ideal softening points between 46°C and 54°C balance thermal stability with flexibility.

- Roads in Phoenix require binders with higher softening points to resist 60°C+ surface temperatures

- Minnesota pavements need lower thresholds (-20°C winter flexibility)

Impact on Asphalt Mix Design and Binder Selection

Test results guide PG (Performance Grade) binder classification. PG 64-22 binders, common in temperate zones, must withstand 64°C high-temperature traffic loads without rutting. Mix designs integrate softening point data with penetration grades for optimized cohesion. Modified binders (SBS, crumb rubber) push softening points beyond 80°C for heavy-use zones like ports or intersections.

Contractors use this data to:

- Select binders matching regional climate extremes

- Adjust aggregate gradation for thermal expansion rates

- Set compaction temperatures within 10°C of softening points

With performance links established, let’s examine the tools driving precise softening point measurement. Next, we’ll break down ring-and-ball apparatus setups, calibration protocols, and testing workflows.

Testing Methods and Equipment

Bituminous materials show distinct physical shifts as warmth rises. Pinpointing this shift requires specific tools and strict protocols to maintain accuracy across labs and job sites.

Key Tools for Softening Point Testing

Labs rely on specialized tools to find the warmth level at which bituminous binders start flowing. Missing or faulty parts can skew data, impacting mix designs.

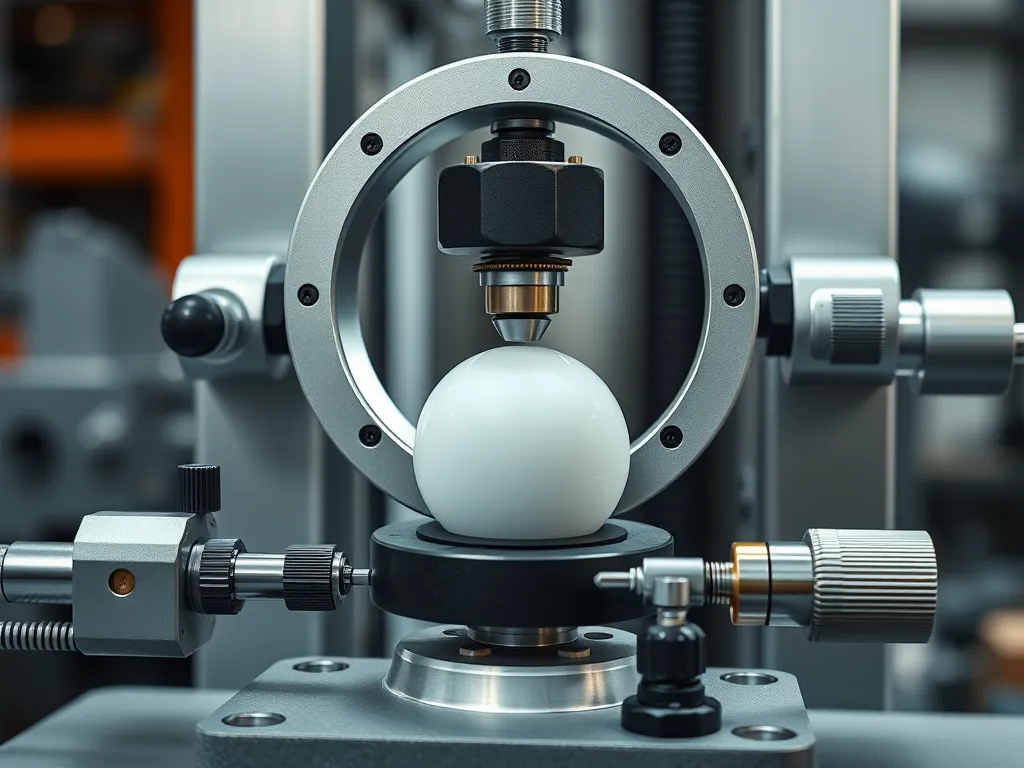

Ring-and-Ball Apparatus Explained

A brass ring holds a 19.8g bitumen sample, while two 9.5mm steel balls sit on top. This setup submerges in a liquid bath warming at 5°C/min. When bitumen softens enough to let a ball drop 25mm, that warmth marks its softening point. Most labs run two trials, averaging results within 1°C.

Calibration and Tool Upkeep

Annual calibration checks confirm bath warming rates stay at 5±0.5°C/min. Daily tasks include scrubbing rings with toluene to strip old residues. Ball surfaces must stay smooth—replace any with dents above 0.1mm depth. Digital thermometers need validation against NIST-traceable units yearly.

Step-by-step Testing Protocol

Following a rigid process cuts variability. Diverging from norms risks misclassifying binders, leading to pavement failures in hot zones.

Getting Bitumen Samples Ready

Heat 60/70 grade material to 150°C until fully liquid. Pour into pre-warmed rings, avoiding air gaps. Cool at 5°C for 30 minutes, then trim excess with a hot blade. Store samples at 25°C for 2 hours before testing.

Warming and Tracking Softening

Fill baths with glycerin (for points above 80°C) or water. Mount rings on a frame, place balls on samples, then submerge. Start at 5°C below anticipated softening point. Record warmth when each ball touches the base plate. Stop tests if results vary by over 2°C.

Global and Regional Testing Norms

Standards align methods across borders, vital for global asphalt trade. Shifting between specs can alter outcomes by 3-5°C.

ASTM D36 and AASHTO T53 Rules

ASTM D36 allows both water and glycerin baths, while AASHTO T53 requires glycerin for all trials. Both set a 5°C/min warming rate but differ in ball-drop detection—ASTM uses visual checks; AASHTO permits automated sensors.

ISO 4625 and Local Codes

ISO 4625-2 uses a brass cup instead of rings, common in Asian and African markets. Brazil’s NBR 15184 mirrors ASTM but tightens sample prep times. Australia’s AGPT/T231 adds a stirrer to baths for uniform warmth distribution.

With norms shaping how labs measure flow traits, grasping grade-specific thresholds becomes vital—particularly for 60/70 bitumen dominating road projects.

Also See: Comparative Noise Studies: Asphalt Vs Concrete

Softening Point Of 60/70 Bitumen in Asphalt Applications

60/70 penetration grade bitumen dominates road construction globally due to its balanced viscosity-temperature relationship. The softening point test of bitumen determines how this binder performs under heat stress – a critical factor for asphalt pavements exposed to traffic loads and climate extremes.

Typical Range and Significance for Road Construction

The bitumen softening point for 60/70 grade typically falls between 46°C and 54°C when tested via ASTM D36 ring-and-ball method. This range directly impacts pavement behavior: values below 46°C increase rutting risks in hot climates, while exceeding 54°C may cause brittleness and thermal cracking in colder regions. Engineers correlate these results with Superpave Performance Grades (PGs) like PG 64-22, where the first number (64°C) aligns with maximum service temperatures the binder can withstand without deforming.

Highways in Arizona or Texas often specify 60/70 bitumen with softening points near 52°C to resist softening under 140°F asphalt temperatures. Coastal projects prioritize lower ranges (48-50°C) to maintain flexibility in humid, cooler conditions. Deviations over ±2°C from project specifications trigger mandatory binder reformulation to prevent premature pavement failures.

Quality Control for 60/70 Grade Asphalt Binders

Labs conduct bitumen softening point determination every 200 tons of binder production. Technicians prepare samples using precisely leveled brass rings and glycerin baths, adhering to AASHTO T53 heating rates of 5°C/minute. Modern labs use automated ring-and-ball testers with ±0.1°C accuracy, reducing human error in asphalt softening point measurement.

Polymer-modified 60/70 binders require stricter protocols. Adding 3% SBS elastomer can elevate softening points by 8-12°C, demanding adjusted testing parameters. QC teams cross-verify results with penetration tests (60-70 dmm at 25°C) and ductility values (>100cm at 25°C) to ensure comprehensive compliance. Failed tests cost producers $12-18/ton in reprocessing fees – a strong incentive for rigorous softening point monitoring.

Up next: While softening point tests predict high-temperature performance, they’re often confused with melting point analyses. Let’s clarify why asphalt engineers prioritize softening point data over traditional melting metrics.

Softening Point Vs. Melting Point in Asphalt Context

While both terms describe thermal behavior, softening point and melting point define distinct asphalt binder properties. The softening point test identifies the temperature at which bitumen becomes pliable enough to deform under controlled loads. Melting point refers to complete phase change from solid to liquid—a transition asphalt binders never experience under normal service conditions.

Technical Distinctions and Practical Implications

Bitumen softening point determination relies on standardized methods like ASTM D36 using ring-and-ball apparatus. Tests record the exact temperature where a sample softens enough to let a steel ball sink 25mm. Melting point stays undefined for asphalt binders due to their complex hydrocarbon mix. This difference impacts pavement performance: binders with low softening points (below 40°C) risk rutting in summer heat, while those above 80°C may crack during winter.

PG (Performance Grade) binder specifications use softening point data to match materials to climate zones. For example, 60/70 grade bitumen’s 46-54°C range balances flexibility and stability for most road projects. Melting point remains irrelevant here, as asphalt pavements operate at temperatures far below any theoretical phase shift.

Why Softening Point Matters More for Asphalt Performance

Road surfaces endure temperatures from -30°C to 60°C—well within bitumen’s viscoelastic range. Softening point testing predicts binder behavior under these conditions. A high softening point (above 55°C) resists deformation in desert climates, while lower values (around 45°C) prevent brittleness in colder regions. Superpave mix designs integrate this data to optimize aggregate-bitumen adhesion.

Melting point tests lack standardization for asphalt binders. Unlike metals or waxes, bitumen softens gradually without a clear liquid transition. Focus on softening point ensures pavements withstand traffic loads without bleeding or cracking—key factors in achieving 20+ year service life for highways.

Accurate softening point measurement bridges lab tests to real-world performance. Up next: troubleshooting common errors that skew test results.

Troubleshooting and Best Practices

Even skilled labs face issues in bitumen softening point tests. Spotting errors early keeps data true to real-world asphalt performance.

Common Testing Errors in Asphalt Laboratories

Frequent slips include:

- Heating rate over 5°C/min – warps bitumen flow

- Ball guides not cleaned – adds drag to samples

- Wrong test start temps (below 5°C for 60/70 grade)

ASTM D36 and AASHTO T53 note these points. Labs using asphaltite softening point tests must track room temps. Even 2°C shifts change results.

Optimizing Water Volume for Accurate Results

Water baths need strict control. Use 800 mL ±5 mL for ring-and-ball tests. Low levels let heat climb too fast. High levels slow heat spread. Labs check levels each test cycle. For asphalt softening point tests, keep bath depth at 51 mm. Add ice chips if room temps spike past 30°C.

Sample Reuse and Calibration Guidelines

Never reuse samples. Aged bitumen alters flow traits. Steel balls and rings need checks every 90 days. Steps:

- Clean tools with xylene post-test

- Track ball wear with calipers

- Replace rings if bends exceed 0.25 mm

ISO 4625 sets reuse rules. Labs log each test batch. Mix logs with asphalt cement specs to spot trends.

These steps set the stage for eco-friendly testing. Next, we break down how labs cut waste while keeping data sharp.

Environmental Considerations in Softening Point Testing

Asphalt labs face growing pressure to cut waste and energy use while running bitumen softening point tests. Eco-friendly steps now shape how teams handle used samples and gear.

Waste Management for Asphalt Testing Labs

Each softening point test leaves steel rings, bitumen scraps, and solvent bottles. Labs reuse steel parts up to 95% after cleaning, per ASTM D36 rules. Used asphalt binders get recycled into new test batches or road patches. Proper solvent disposal stops soil leaks – EPA rules demand sealed drums for transport to treatment sites. Smart waste plans cut lab costs by 18% yearly while meeting RCRA guidelines.

Energy Efficiency in Repeated Testing

Heating baths in ring-and-ball tests eat 65% of a lab’s energy. Digital controllers trim oven runtimes by 22% versus old dial units. Bulk testing (5+ samples at once) slashes per-test power needs. New ASTM D36-21 allows lower start temps (5°C less) for some binders, saving 800 kWh yearly per lab. Solar-heated water baths cut fossil fuel use in sample prep by 40%.

Green testing methods now shape asphalt quality checks. Up next: Answers to top questions about softening point norms and field use cases.

FAQs on Bitumen Softening Point Testing

What is the Softening Point Of Bitumen According to ASTM D36?

The softening point of bitumen, as measured by ASTM D36, is defined as the temperature at which a sample of bitumen softens sufficiently to allow a steel ball to drop a specified distance under controlled conditions. This temperature is crucial for understanding the performance characteristics of bitumen in various environmental conditions, especially in roadway applications.

What is the Difference Between Softening Point and Melting Point for Asphalt Binders?

The softening point is the temperature at which the bitumen softens enough to flow under a specific load, while the melting point typically refers to the complete transition from solid to liquid. Asphalt binders, however, do not have a defined melting point since they do not undergo a complete phase change within operational temperatures. The softening point is a more relevant measurement for evaluating asphalt performance.

Which Equipment is Standard for Asphalt Softening Point Testing?

The standard equipment used for asphalt softening point testing is the ring-and-ball apparatus. This includes a specific setup with brass rings, steel balls, and a bath for heating the samples. These components work together to accurately measure the temperature at which the asphalt begins to soften.

Why is 60/70 Bitumen Softening Point Critical for Road Projects?

The softening point of 60/70 bitumen is critical for road projects because it directly affects the durability and performance of pavements under different temperature conditions. A proper softening point range (typically between 46°C and 54°C) ensures that the asphalt can withstand high temperatures in warm climates without deforming, while also providing the necessary flexibility in cooler conditions to prevent cracking.

Closing Thoughts

Understanding bitumen softening point testing is vital for ensuring the quality and durability of asphalt applications. By examining softening points, engineers can assess temperature susceptibility and optimize asphalt mix designs. This testing not only influences material selection but also impacts overall pavement performance.

Accurate testing methods and compliance with standards like ASTM D36 and AASHTO T53 are essential for reliable results. Regular calibration of equipment and adherence to best practices can eliminate common errors, leading to more consistent outcomes.

Asphalt Calculator USA is an excellent resource for further information on bitumen properties and asphalt applications. Be sure to visit our site for comprehensive insights on this important topic.