Boost Asphalt Performance With Chemical Curing Additives

Published on: August 29, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Chemical additives in asphalt curing are specialized compounds mixed into asphalt to improve hardening and durability. These additives—like warm mix agents, cold weather modifiers, and rheology enhancers—accelerate curing by 20-40%, strengthen pavement against heavy loads, and enable installation in temperatures as low as 35°F. They’re used in road construction, parking lots, and driveways to create longer-lasting surfaces while cutting material costs by up to 25% compared to traditional methods.

This article breaks down how chemical additives transform asphalt curing. You’ll learn about key types such as Warm Mix Asphalt (WMA) additives and sulfur-based solutions, explore benefits like faster project timelines and reduced emissions, and get practical tips for selecting and applying additives effectively.

Contents

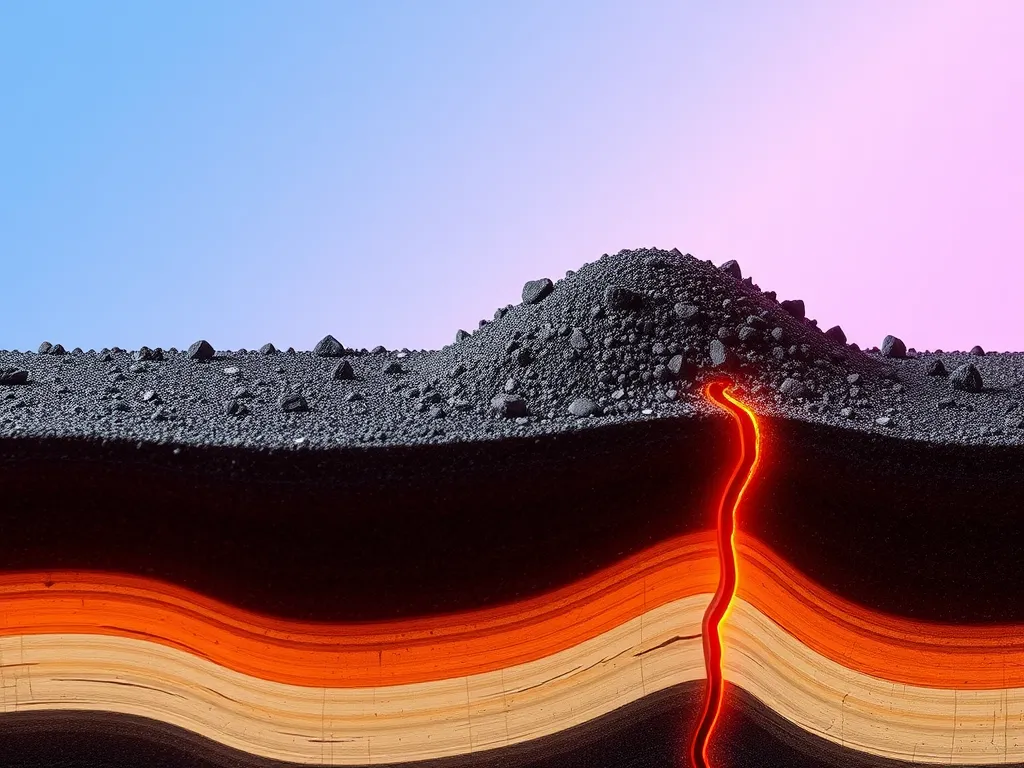

What Are Chemical Additives in Asphalt Curing?

Chemical additives for asphalt curing are specialized substances blended into mixtures to modify curing properties. These materials optimize performance under varying traffic loads, weather conditions, or production demands. Common types include polymers, sulfur-based modifiers, or rheology enhancers. They integrate with PG (performance-graded) binders—designed for specific climate ranges—or Superpave mixes engineered for precise volumetric consistency.

How Chemical Additives Enhance Asphalt Curing

These additives interact molecularly with bitumen during curing. Polymers form cross-linked bonds boosting tensile strength by 15-20%, while sulfur-based options increase stiffness for heavier loads. Rheology modifiers lower viscosity, letting work crews compact mixtures efficiently even below 50°F. Warm mix additives cut production temps by up to 50°F, slashing energy use by 15%. Curing times drop 30-40%, speeding up project timelines without compromising density. Reduced emissions—up to 20% less CO₂ per ton—support greener operations.

Exploring common additive types used in projects reveals even more benefits tied to specific climate needs.

Common Types Of Chemical Additives for Asphalt Curing

Distinct groups of asphalt curing chemical additives tackle specific challenges in road construction. From cutting production temps to boosting cold-weather performance, each category serves a unique role in asphalt mixture optimization.

Warm Mix Asphalt (WMA) Additives

WMA additives allow asphalt production at 20-55°F lower temps than traditional hot mix (HMA). This cuts fuel costs by up to 35% while maintaining compaction quality. Common options include organic waxes and liquid surfactants.

Types and Mechanisms of Warm Mix Additives

Sasobit’s organic waxes harden during cooling, stabilizing mixes faster. Evotherm uses surfactant technology to coat aggregates at lower temps. Rediset additives combine adhesion promoters with viscosity reducers, aiding workability below 280°F.

Cold Weather Asphalt Additives

Anti-stripping agents like liquid amines prevent moisture damage during freeze-thaw cycles. Viscosity modifiers maintain mix flow down to 15°F, allowing winter paving without compromising density targets. Projects in states like Minnesota report 18% longer winter paving windows using these formulas.

Sulfur-based Additives

Sulfur extends asphalt binder volume by 30-40% in some mixes. It stiffens pavements at high temps while cutting raw material costs. Trials on I-35 in Texas showed sulfur-modified sections withstood rutting 22% better than conventional asphalt after 3 years.

Rheology Modifiers

Polymeric additives like styrene-butadiene-styrene (SBS) alter asphalt’s flow properties. They boost crack resistance by 50% in PG 76-22 binders compared to unmodified mixes. Crosslinking agents create 3D networks within the binder, improving load distribution across pavement layers.

Looking past additive types, actual job gains hinge on how these formulas interact with mix designs and local conditions. Up next: quantifying how chemical additives for asphalt curing translate into lasting pavement performance.

Key Benefits Of Chemical Additives in Asphalt Curing

Chemical additives transform asphalt curing by optimizing material performance at every stage. These formulations target specific challenges like weather delays, structural weaknesses, and long-term maintenance costs. Let’s break down their measurable advantages.

Accelerated Curing Times

Amine-based or siloxane additives slash curing periods by 30-50%, letting crews reopen roads in 2-4 hours versus 8-12. Projects in rainy regions like Seattle report 45% faster lane returns when using curing catalysts. This speed minimizes traffic disruptions and weather-related delays during placement.

Improved Durability and Load Resistance

Polymer-modified additives boost asphalt’s Marshall Stability values by 25-40%, directly combating rutting and cracking. Texas DOT observed 37% fewer potholes on I-35 stretches treated with styrene-butadiene-styrene (SBS) modifiers. These blends handle heavier axle loads – critical for highways averaging 3,000+ trucks daily.

Enhanced Workability in Extreme Temperatures

Anti-strip additives maintain mix integrity from -10°F to 140°F. In Alaska, polyethylene wax additives let crews pave at 15°F without thermal segregation. Conversely, Arizona contractors use Evotherm® to prevent mix stiffening during 110°F summer pours. Both scenarios retain optimal compaction densities above 92%.

Reduced Production Costs

Warm-mix asphalt (WMA) additives cut plant temperatures by 50-100°F, trimming fuel costs 15-20%. A Michigan plant saved $8,700 weekly using Sasobit® at 185°F instead of 290°F. Lower temps also extend drum life – plants report 18-24 months between liner replacements versus 12 months with hot mixes.

Environmental Advantages

Modern additives align with EPA’s ENERGY STAR® guidelines for industrial materials. Their dual impact on emissions and energy reshapes asphalt’s carbon footprint.

Lower Energy Consumption

Every 10°F drop in mix temperature saves 1.1 gallons of diesel per ton. WMA production at 275°F versus 325°F reduces fuel use 30% – roughly 42,000 gallons annually for mid-sized plants. This directly lowers Scope 1 emissions tracked under GHG Protocol standards.

Reduced Emissions

Chemical additives suppress volatile organic compounds (VOCs) by 60-70% during laydown. California’s South Coast AQMD found 63% lower PM2.5 emissions from plants using zeolite additives. These cuts help projects meet Clean Air Act thresholds without after-treatment systems.

With these benefits established, let’s examine how to select and apply additives for maximum impact.

Also See: Cooling Vs Curing in Asphalt: Key Differences

Best Practices for Using Chemical Additives

Proper application of asphalt curing chemical additives ensures maximum performance and cost savings. Follow these guidelines to optimize results.

Selecting the Right Additive for Your Project

Match additives to specific needs. For cold climates, use low-temperature modifiers like Evotherm®. High-traffic roads benefit from polymer-modified binders. Check if your asphalt mix uses PG 64-22 or PG 76-22 binders – some additives work better with specific performance grades. Warm mix asphalt (WMA) additives like Sasobit® reduce mixing temperatures by 50°F but require precise temperature control.

Optimal Dosage and Mixing Techniques

Most chemical additives for asphalt perform best at 0.5-2% by weight of binder. Exceeding 3% can weaken pavement. Use high-shear mixers at 280-320°F for even dispersion. For sulfur-based additives, maintain pH above 8 to prevent H2S gas formation. Track viscosity changes – a 15% reduction signals proper additive activation.

Compatibility Testing With Asphalt Mixes

Conduct lab tests before full-scale use. Run Dynamic Shear Rheometer (DSR) checks on modified binders. Verify stability with Marshall Tests – aim for 2,200-lb minimum. Test stripping potential using AASHTO T283. For recycled asphalt pavement (RAP), confirm additives don’t degrade aged binder. Some rheology modifiers clash with anti-strip agents – always test combinations.

These methods ensure chemical additives for asphalt curing deliver their full potential. Next, we’ll address common questions about application challenges and solutions.

Frequently Asked Questions (FAQs)

What Are Warm Mix Asphalt Chemical Additives?

Warm Mix Asphalt (WMA) chemical additives are materials used in asphalt mixtures that allow for production at lower temperatures than traditional Hot Mix Asphalt (HMA). This helps reduce energy consumption and emissions while maintaining the workability of the asphalt. Common additives include organic waxes and surfactants that facilitate binding without compromising the quality of the final product.

What is the Difference Between HMA and WMA?

Hot Mix Asphalt (HMA) is produced at high temperatures (typically around 300°F), while Warm Mix Asphalt (WMA) can be produced at temperatures 20-55°F lower. The lower temperatures associated with WMA reduce fuel consumption, emissions, and thermal segregation during construction, allowing for extended paving seasons and improved environmental performance.

What Additives Are Used for Asphalt in Cold Weather?

Cold weather asphalt additives include anti-stripping agents like liquid amines, which prevent moisture damage, and viscosity modifiers that allow for proper flow of asphalt mixtures at low temperatures. These additives are essential for maintaining the effectiveness and durability of asphalt in freezing or near-freezing conditions.

What Are the Disadvantages Of Warm Mix Asphalt?

While Warm Mix Asphalt offers numerous benefits, some disadvantages include potential incompatibility with certain types of aggregate or binder, the need for precise control over mixing temperatures, and variability in performance depending on the specific additive used. Additionally, it may not always produce the same high initial strength as HMA, depending on other project factors.

Closing Thoughts

Utilizing chemical additives in asphalt curing offers a multitude of benefits. These additives significantly enhance the durability, workability, and cost-effectiveness of asphalt mixes. With the ability to accelerate curing times and improve performance in varying climates, they are vital for modern road construction.

The environmentally friendly aspects of these additives, such as lower energy consumption and reduced emissions, further underscore their importance in sustainable construction practices. By selecting the right additive and following best practices, contractors can optimize their projects and drive overall efficiency.

For more information and resources on asphalt-related topics, visit Asphalt Calculator USA.

Useful References for You:

- What’s in Your Asphalt? | FHWA – Department of Transportation

- Incorporation of Additives and Fibers in Porous Asphalt Mixtures: A Review – PMC

- CHAPTER FOUR Asphalt Additives and Modifiers | Relationship Between Chemical Makeup of Binders and Engineering Performance | The National Academies Press

- The Role of Additives in Warm Mix Asphalt Technology: An Insight into Their Mechanisms of Improving an Emerging Technology – PMC