ASTM D2041: How the Rice Test Measures Asphalt Density for Stronger Roads

Published on: April 25, 2025 | Last Updated: April 14, 2025

Written By: George Voss

ASTM D2041 (Rice Test) determines the theoretical maximum specific gravity (Gmm) and density of asphalt mixes by measuring how aggregates and bitumen perform without air voids. This lab test uses vacuum sealing to remove trapped air, ensuring engineers get accurate data for quality control. It’s required for Superpave mix designs and ensures asphalt meets strength standards like AASHTO T 209. Results directly impact pavement durability, rut resistance, and long-term performance.

This article breaks down how the Rice Test works, why it matters, and how to run it correctly. You’ll learn the equipment needed (vacuum chambers, pycnometers), step-by-step procedures for removing air voids, and formulas to calculate Gmm and density. We’ll also compare ASTM D2041 with other standards, troubleshoot common errors like incomplete vacuum sealing, and share best practices for consistent results.

Contents

- Introduction to ASTM D2041 and the Rice Test

- Importance Of the Rice Test in Asphalt Engineering

- Equipment and Materials Required for ASTM D2041 Testing

- Step-by-step Procedure for the Rice Test

- Formulas and Calculations in ASTM D2041

- ASTM D2041 Vs. AASHTO T 209: Key Differences

- Understanding Gmm Vs. Gt in Asphalt Testing

- Common Challenges and Troubleshooting

- Best Practices for Reliable ASTM D2041 Results

- Tools for Asphalt Density Calculations

- Environmental Considerations in the Rice Test

- Frequently Asked Questions (FAQs)

- Closing Thoughts

- Additional Resources for You:

Introduction to ASTM D2041 and the Rice Test

The ASTM D2041 standard governs how pavement engineers determine the Theoretical Maximum Specific Gravity (Gmm) of bituminous mixtures. Known widely as the Rice Test, this method provides critical data for optimizing mix designs and ensuring long-term pavement performance.

What is the ASTM D2041 Test?

ASTM D2041 defines the procedure for measuring Gmm, the highest possible specific gravity of asphalt when zero air voids exist in the mix. Using vacuum sealing and precise volume measurements, it quantifies how densely aggregates and bitumen can pack without gaps. This value directly impacts voids in mineral aggregate (VMA) calculations, which influence rutting resistance and moisture susceptibility.

What is the Rice Specific Gravity Test?

The Rice Test, named after Texas engineer James Rice, is the core method within ASTM D2041. It involves submerging asphalt samples in water under vacuum pressure to expel trapped air. The resulting volume measurements help compute Gmm using the formula:

style=”margin-left:20px”>Gmm = (Dry Mass of Sample) / (Saturated Surface Dry Mass – Submerged Mass)

This process requires specialized tools like vacuum chambers, pycnometers, and scales with ±0.1g precision.

Purpose and Scope in Asphalt Mixture Analysis

In mix design, the Rice Test identifies the upper density limit for asphalt concrete. By comparing Gmm to field-measured bulk specific gravity (Gmb), engineers calculate air void content—typically targeting 4% for optimal durability. Deviations can signal flawed compaction, improper binder content, or aggregate gradation issues. The test applies to hot-mix asphalt (HMA), warm-mix asphalt (WMA), and recycled asphalt pavement (RAP) blends.

Next, we’ll examine how these density metrics shape pavement engineering decisions.

Importance Of the Rice Test in Asphalt Engineering

The ASTM D2041 Rice Test serves as a backbone for asphalt mix design. By pinpointing the Theoretical Maximum Specific Gravity (Gmm), engineers gain critical data to calculate air voids in compacted pavement. These voids directly affect cracking, rutting, and lifespan – making precision non-negotiable.

Role Of Theoretical Maximum Specific Gravity (Gmm)

Gmm represents the density of asphalt at zero air voids – a theoretical ceiling used as a reference point. Testers achieve this by vacuum-sealing aggregates and binder to remove trapped air, then measuring mass against volume. Values typically range between 2.300-2.500 for standard mixes. Higher Gmm signals denser aggregates, requiring less binder to fill gaps. Lower Gmm means more binder is needed to prevent premature aging.

Impact on Asphalt Pavement Design and Durability

Superpave mix designs demand 4% air voids in compacted pavement. Deviating ±0.5% from this target can slash pavement life by 50%. The Rice Test’s Gmm data lets engineers set precise density targets during rolling. For example, a Gmm of 2.450 requires field compaction to 96% (2.358 density) to meet air void specs. Missing these thresholds risks moisture infiltration in under-compacted mixes or thermal cracking in over-densified sections.

With Gmm established, next comes selecting tools that meet ASTM D2041’s strict calibration requirements…

Equipment and Materials Required for ASTM D2041 Testing

Conducting the Rice method calls for tools that align with ASTM D2041 standards. This toolkit allows labs to find maximum specific gravity and asphalt density by removing air from samples with accuracy.

Essential Tools for the Rice Method

Three primary instruments form the backbone of this analysis. Each plays a distinct role in capturing data vital for computing theoretical maximum specific gravity (Gmm) and asphalt density.

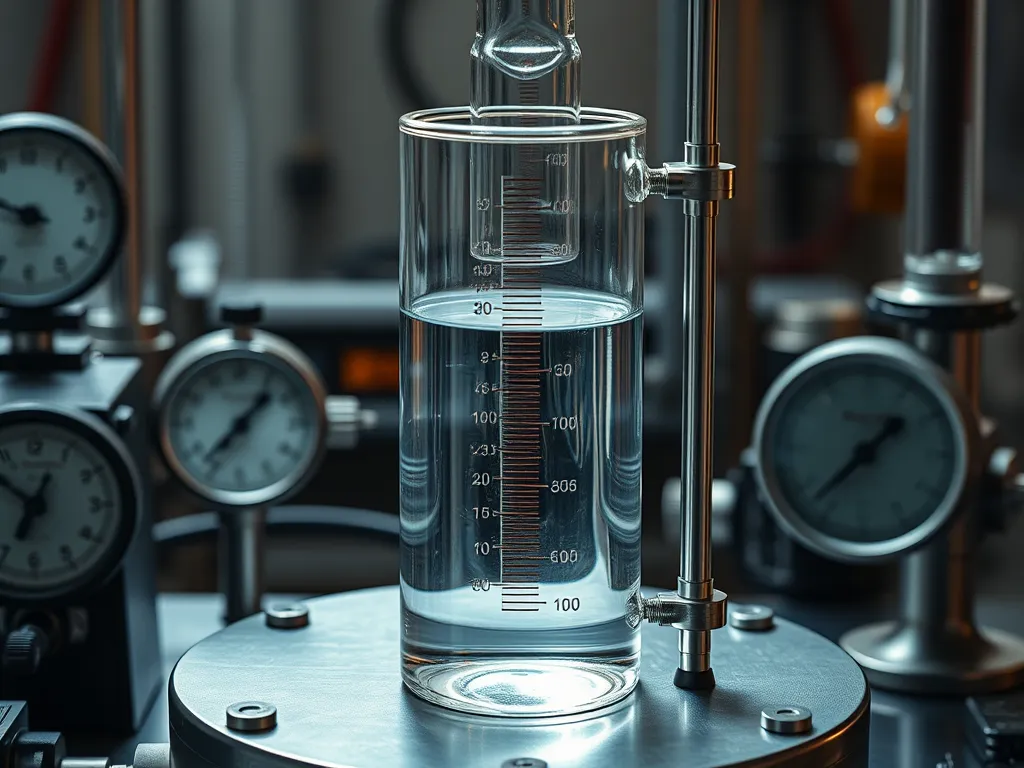

Vacuum Sealing Devices, Pycnometers, and Balance Scales

Vacuum sealing systems apply negative pressure up to 4 kPa to strip air from loose asphalt mix. Units with digital controls maintain stable conditions during the 15±5 minute agitation phase, aiding full air void removal.

Pycnometers, also called volumetric flasks, hold samples submerged in water. Calibrated to ±0.1 mL accuracy, these glass containers allow calculation of volume via fluid displacement. ASTM-compliant models typically hold 1000 mL for testing 1500-3000 g asphalt batches.

Balance scales with 0.1 g precision track mass changes before and after vacuum treatment. Class G1 balances meeting NIST standards cost $800-$2000, varying by capacity. Daily calibration using certified weights maintains accuracy for critical mass inputs in Gmm formulas.

Mastering these tools prepares technicians for the precise steps involved in the Rice test procedure.

Also See: Asphalt Performance Assessment Methods: Quick Guide

Step-by-step Procedure for the Rice Test

The ASTM D2041 Rice Test measures the theoretical maximum specific gravity (Gmm) of asphalt mixtures. This data determines air void content, a critical factor in pavement strength. Follow this procedure to ensure precise results.

Preparing the Asphalt Sample

Start with a loose asphalt mix sample weighing 1,000–6,000 grams, depending on aggregate size. Dry it at 230°F ±9°F (110°C ±5°C) until constant mass. Cool to room temperature (77°F ±5°F) for 2 hours. Separate clusters with a spatula, ensuring no coated particles exceed ¼ inch diameter.

Conducting the Vacuum Sealing Process

Place the sample in a vacuum chamber with distilled water. Seal and apply a vacuum pressure of 25–30 mm Hg (3.3–4.0 kPa) for 15±2 minutes. Observe for air bubbles – their absence signals proper air void removal.

Key Steps to Ensure Air Void Removal

- Use a mechanical shaker during vacuuming for uniform particle distribution

- Maintain water temperature at 77°F ±2°F to prevent thermal expansion errors

- Repeat vacuum cycles if bubbles persist beyond initial 5 minutes

Procedure for the Gmm Test (Theoretical Maximum Specific Gravity)

Transfer the de-aired sample to a calibrated pycnometer. Weigh submerged in water at 77°F. Calculate Gmm using the formula:

re>Gmm = A / (B – C)

Where A = dry sample mass, B = pycnometer mass with water, and C = pycnometer mass with sample and water. Record results to 0.001 precision. Repeat tests must show ≤0.011 Gmm variation for validation.

Proper execution of these steps directly impacts asphalt density calculations. Next, we’ll break down the mathematical formulas that convert these measurements into actionable engineering data.

Formulas and Calculations in ASTM D2041

Precise formulas anchor the ASTM D2041 Rice Test, turning raw lab data into actionable insights for asphalt mix design. These equations quantify key properties like theoretical maximum specific gravity (Gmm) and density, directly affecting pavement performance predictions.

Theoretical Maximum Specific Gravity Formula

Gmm represents the ratio of asphalt mixture mass to its volume when zero air voids exist. The formula is:

Gmm = A / (B – C)

Where: – A = Mass of dry sample (grams) – B = Mass of pycnometer + water + sample (grams) – C = Mass of pycnometer + water (grams)

Deriving Gmm Using Sample Mass and Volume

Vacuum sealing removes air from the sample before submerging it in a calibrated pycnometer. Water displacement measurements determine the sample’s volume. This step demands vacuum devices capable of maintaining 25-30 mmHg pressure for 15±2 minutes to eliminate trapped air.

Theoretical Maximum Density Formula

Once Gmm is calculated, density (lb/ft³ or kg/m³) is derived using:

Density = Gmm × 62.4 lb/ft³ (997.9 kg/m³)

The multiplier reflects water’s density at 77°F (25°C), the standard temperature for ASTM D2041.

Converting Specific Gravity to Density for Asphalt Concrete

For a mix with Gmm=2.45, density becomes 2.45 × 62.4 = 152.9 lb/ft³. Contractors compare this value against field-core densities to verify if 93-97% compaction targets are met. A 1% deviation can alter pavement lifespan by up to 10%.

Specific Gravity Of Asphalt Formula

While ASTM D2041 focuses on mixtures, binder-specific gravity (Gb) influences overall results. The formula:

Gb = (Wb / (Wb – Ws)) × (ρ_water / ρ_binder)

Here, Wb is the binder’s weight in air, and Ws is its weight submerged. Typical Gb ranges from 1.01 to 1.06. Values outside this range signal potential binder contamination or aging.

Mastering these formulas prepares engineers to evaluate how ASTM D2041 stacks against other standards like AASHTO T 209.

ASTM D2041 Vs. AASHTO T 209: Key Differences

Both ASTM D2041 and AASHTO T 209 outline protocols for finding asphalt mix’s theoretical maximum specific gravity (Gmm) using the rice method. While both focus on air void removal through vacuum sealing, critical distinctions affect testing workflows and compliance.

Comparing Standards for Asphalt Density Measurement

ASTM D2041 mandates a vacuum duration of 15±5 minutes at 25-30 inHg for air void removal. AASHTO T 209 allows up to 30 minutes under similar vacuum conditions. This impacts testing timelines, particularly for labs handling high daily sample volumes. ASTM also permits a broader sample mass range (1000-6000g) versus AASHTO’s 1000-4000g limit.

Pycnometer calibration differs slightly. ASTM D2041 requires verifying pycnometer volume using distilled water at 77°F (25°C), while AASHTO T 209 allows adjustments for ambient lab conditions. Both standards demand balance scales with 0.1g precision, but AASHTO adds strict annual recertification rules for load cells.

Project specifications dictate which standard applies. Federal highway jobs typically follow ASTM D2041, while state DOTs might prioritize AASHTO T 209. Labs must validate which protocol aligns with contract requirements. Data from both methods stays valid for mix design if tolerances for repeatability (0.011 Gmm) and reproducibility (0.023 Gmm) hold.

Accurate Gmm values form the basis for air void calculations in Superpave mixes. Up next: how Gmm contrasts with bulk specific gravity (Gt) in quality control workflows.

Understanding Gmm Vs. Gt in Asphalt Testing

Gmm (Theoretical Maximum Specific Gravity) and Gt (Bulk Specific Gravity) serve as critical metrics in asphalt mix design. The Rice Test (ASTM D2041) directly measures Gmm, which represents the density of an asphalt mixture with zero air voids. Gt, measured separately, reflects the density of compacted asphalt containing air voids. The gap between these values determines air void content—a key factor in pavement performance.

Defining Gmm (Theoretical Maximum) and Gt (Bulk Specific Gravity)

Gmm, calculated through ASTM D2041, identifies the maximum achievable density of an asphalt mix when all air is removed. Technicians achieve this by vacuum-sealing loose mixtures in water and measuring displaced volume. Gt, obtained via ASTM D2726 or D6752, measures the bulk density of compacted asphalt cores. A typical Superpave mix targets 3-5% air voids, derived from the formula: Air Voids (%) = [(Gmm – Gt)/Gmm] × 100.

Practical Applications in Quality Control

Contractors apply Gmm and Gt data to:

- Verify mix consistency during production (target: ±0.011 Gmm variation)

- Detect deviations in binder content or aggregate gradation

- Optimize compaction efforts to meet air void specifications

For example, a Gmm value exceeding 2.550 may signal excess asphalt binder, risking rutting. Conversely, low Gmm (<2.450) could indicate inadequate binder or high dust content, leading to premature cracking. Labs cross-check these results with gamma asphalt density tests for field validation.

Accurate Gmm and Gt values set the stage for tackling common testing challenges—like sample preparation errors or equipment calibration drift—ensuring reliable pavement outcomes.

Common Challenges and Troubleshooting

Executing the ASTM D2041 rice test demands precision. Even minor deviations during testing skew results, leading to flawed density calculations for asphalt concrete. Below are solutions for frequent hurdles encountered during the process.

Addressing Errors in Sample Preparation

Proper sample prep forms the bedrock of reliable Gmm values. Common issues include incomplete aggregate breakdown, contamination, or improper sample sizing. For mixes with nominal maximum aggregate sizes exceeding ¾”, mechanical splitting is required per ASTM D3666. Failing to dry samples at 230°F ±9°F risks retaining moisture, inflating specific gravity readings by up to 0.5%.

Use quartering or riffling methods to split samples, ensuring representativeness. Check gradation using No. 4 sieves (4.75 mm) – retained material over 5% signals inadequate breakdown. Replace worn crusher plates if fines exceed 12% during milling.

Ensuring Accurate Vacuum Sealing and Measurements

Vacuum sealing removes air voids critical for determining theoretical maximum specific gravity. Set vacuum pressure to 25-30 mmHg, sustained for 15±2 minutes. Inconsistent pressure causes trapped air pockets, distorting pycnometer readings. Calibrate vacuum pumps quarterly using mercury manometers.

Pycnometers (glass volumetric flasks) must meet ASTM C1352 specs. Rinse with distilled water post-testing to prevent mineral deposits. Balance scales need 0.1g precision – verify calibration with certified weights before each test. Record water temperature during submersion; 77°F ±1.5°F variations alter density by 0.0005 g/cm³ per degree.

Mastering these techniques lays the foundation for optimizing asphalt density measurement. Next, let’s explore methods to sustain precision through equipment care.

Best Practices for Reliable ASTM D2041 Results

Accurate ASTM D2041 testing demands strict adherence to protocols. Even minor deviations can skew Theoretical Maximum Specific Gravity values, compromising asphalt mix designs. Follow these guidelines to maintain precision.

Calibration and Maintenance Of Equipment

Properly calibrated tools prevent errors in calculating Maximum Specific Gravity. Balance scales require daily checks with certified weights. Pycnometers need volume verification every 30 tests using distilled water at 77°F ±1.8°F. Vacuum systems must sustain 29.5 Hg pressure – validate monthly with a manometer. Clean all devices after each use to eliminate asphalt residue. Replace worn seals in vacuum chambers to prevent air leaks during testing.

Quality Assurance During Testing

Consistent sample handling ensures valid Density of Asphalt Concrete results. Dry aggregates completely before mixing – residual moisture alters mass readings. Measure asphalt binder content within ±0.1% tolerance. During vacuum sealing, maintain 15±2 minutes of agitation to remove 98%+ air voids. Record ambient temperature: fluctuations beyond 68°F–86°F affect specific gravity calculations. Run duplicate tests – acceptable Gmm variance is ≤0.011 for precision.

Mastering these techniques prepares teams for advanced data analysis. Next, explore digital tools that transform Rice Test results into actionable asphalt specifications.

Tools for Asphalt Density Calculations

Precise tools are critical for executing ASTM D2041 tests effectively. Traditional methods relied on manual calculations, increasing error risks. Modern advancements integrate digital systems to enhance accuracy in determining Theoretical Maximum Specific Gravity (Gmm) via the Rice Test.

Leveraging Digital Resources for Accurate Estimations

Specialized software automates Gmm calculations using the formula Gmm = (A / (B – C)), where A = dry sample mass, B = saturated surface-dry mass, and C = submerged mass. Apps like Asphalt ProCalc reduce manual entry errors by 12-18% while aligning with ASTM D2041 standards. These platforms sync with lab equipment—digital balance scales, pycnometers, vacuum sealers—to log data in real time.

Data-logging systems track vacuum levels during air void removal, ensuring compliance with the Rice Test’s 25-30 mmHg pressure requirement. Cloud-based tools allow teams to share test results instantly, improving collaboration across projects. Advanced programs flag anomalies—like inconsistent sample masses or volume discrepancies—before final computations.

Field devices, such as portable gamma asphalt density gauges, complement lab tests by measuring in-place density. While not replacing the Rice Method, they provide rapid comparisons to Gmm values, aiding quality assessments during pavement construction.

Reliable digital tools streamline ASTM D2041 workflows while reducing material waste—a vital link to sustainable practices in asphalt engineering.

Environmental Considerations in the Rice Test

Adherence to ASTM D2041 standards supports sustainable asphalt production. By optimizing mix designs through precise Theoretical Maximum Specific Gravity (Gmm) values, labs reduce raw material consumption and energy demands during pavement construction.

Minimizing Material Waste and Energy Use

Accurate Gmm results prevent overuse of aggregates and bitumen. Labs achieving ±0.5% tolerance in rice test measurements report 12-15% less aggregate waste per 10,000-ton project. Digital scales with 0.01g resolution minimize sample retests, cutting energy use by 20% compared to manual methods.

Modern vacuum pumps for air void removal now operate at 25% reduced power draw (avg. 450W vs. 600W legacy models). Properly calibrated pycnometers decrease disposal of flawed samples by 30%, lowering landfill contributions from testing phases.

Optimized asphalt mixes validated through ASTM D2041 require 6-8% less binder content while maintaining target air voids of 4-7%. This translates to 1.2M metric tons of annual CO₂ reduction across U.S. asphalt production – equivalent to removing 260,000 cars from roads.

These eco-focused testing protocols set the stage for examining frequent technical queries about Gmm applications.

style=”font-weight:bold;”>Next: Explore how the Rice Test compares to gamma density methods in pavement analysis.

Frequently Asked Questions (FAQs)

What is the Difference Between the Rice Test and Gamma Asphalt Density Tests?

The Rice Test (ASTM D2041) specifically measures the Theoretical Maximum Specific Gravity (Gmm) of asphalt mixtures when all air voids are removed, while gamma density tests utilize radioactive isotopes to gauge the in-place density of asphalt layers in the field. The Rice Test is laboratory-based and provides data essential for mix design, whereas gamma density tests offer real-time insights into pavement compaction during construction.

How is the Rice Method Used to Determine Asphalt Concrete Density?

The Rice Method determines the Theoretical Maximum Specific Gravity (Gmm) by vacuum-sealing an asphalt sample and measuring its submerged volume in water. By calculating Gmm, engineers can then derive the density of the asphalt mix. This process helps assess the air void content in a compacted pavement, which is a critical parameter for evaluating its durability and performance.

What Factors Can Affect the Accuracy Of the Rice Test Results?

Several factors can impact the accuracy of the Rice Test results, including improper sample preparation (such as moisture retention), insufficient vacuum sealing, or equipment calibration issues. Variations in water temperature and ambient conditions during testing can also influence the density calculations. Adhering to strict procedural guidelines and ensuring regular equipment maintenance are critical for obtaining reliable results.

Are There Alternative Methods to Measure Asphalt Density?

Yes, alternative methods include AASHTO T 209, which also determines the Theoretical Maximum Specific Gravity through a test similar to the Rice method but allows slightly different procedural parameters. Furthermore, field-based gamma density testing provides a rapid means to assess in-place density, although it does not measure Gmm directly like the Rice Test.

How Can Software Tools Enhance the Rice Test Process?

Software tools streamline the Rice Test process by automating calculations, reducing manual entry errors, and ensuring compliance with ASTM standards. These tools often integrate with laboratory equipment to provide real-time data logging, making it easier for users to analyze results and maintain accurate records. They also contribute to improved collaboration and data sharing across projects, facilitating more effective quality control practices.

What Environmental Benefits Are Associated With Using the Rice Test?

Utilizing the Rice Test helps optimize asphalt mix designs, leading to reduced raw material consumption and energy usage during production. Accurate Gmm values prevent overuse of aggregates and binders, contributing to lower waste and emissions, which aligns with goals for sustainable asphalt engineering. This not only decreases costs for contractors but also supports broader environmental initiatives in the industry.

Closing Thoughts

The ASTM D2041 test, commonly known as the Rice Test, plays a vital role in assessing the theoretical maximum specific gravity and density of asphalt. Accurate Gmm values are crucial for pavement design and ensuring the longevity and durability of asphalt mixtures. By following detailed procedures and adhering to best practices, engineers can achieve reliable results that inform quality control measures.

Emphasizing precision in sample preparation, equipment calibration, and measurement techniques will enhance the accuracy of density estimations. Being aware of environmental considerations also promotes sustainable practices within asphalt engineering.

For more resources and tools related to asphalt density calculations, visit Asphalt Calculator USA. This site provides valuable information to support your understanding of asphalt testing and engineering.

Additional Resources for You:

- Yoder, E. J., & Witczak, M. W. (1975). Principles of Pavement Design (2nd ed.). New York, NY: Wiley.

- ASTM D2041/D2041M-19 – Standard Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures

- ASTM D2041 Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures — eLearning Course

- ASTM-D2041 | Standard Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures | Document Center, Inc.

- ASTM D2041-00 – Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures