Asphalt Sustainability Initiatives for Safer Roads

Published on: August 2, 2025 | Last Updated: April 14, 2025

Written By: George Voss

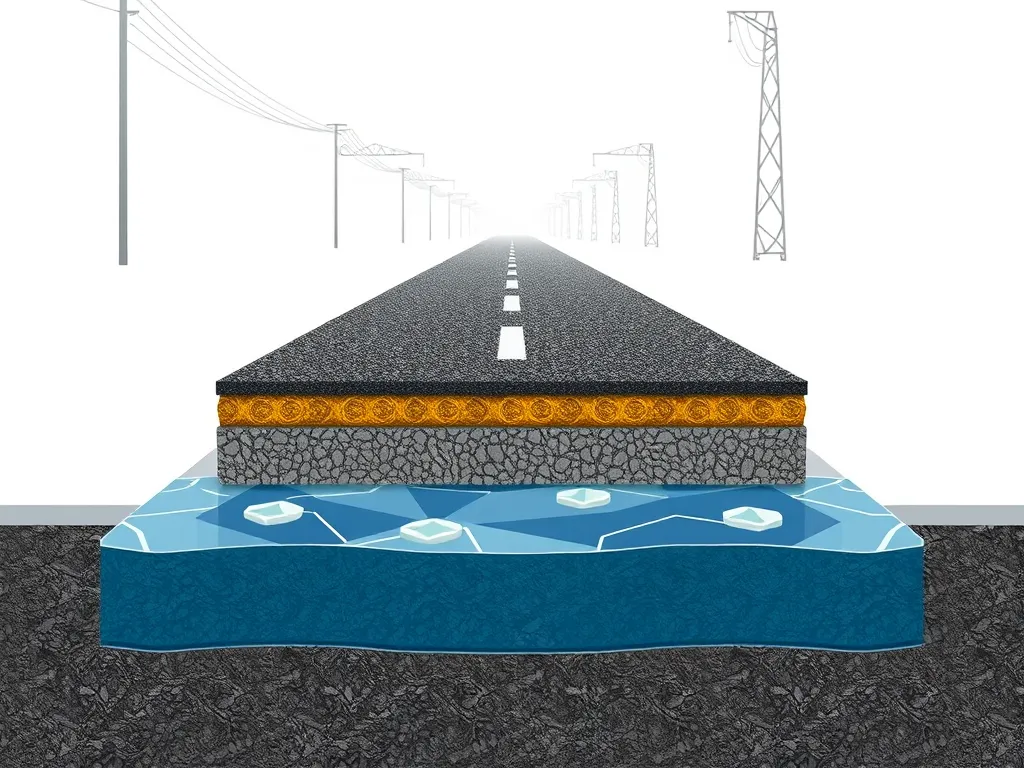

Asphalt sustainability initiatives for safer roads combine eco-friendly construction methods with advanced engineering to create durable surfaces that protect drivers and the environment. These programs focus on recycled materials like Reclaimed Asphalt Pavement (RAP), energy-efficient production techniques such as Warm Mix Asphalt (WMA), and designs that extend pavement life. State DOTs, contractors, and researchers collaborate to reduce emissions by 20-35%, improve skid resistance, and cut costs while meeting safety standards.

This article explains how sustainable asphalt practices work and why they matter. You’ll learn about RAP recycling, rubber-modified mixes, and plant upgrades that slash fuel use. We’ll detail how these methods create quieter roads, prevent weather-related cracks, and keep 90 million tons of waste out of landfills annually. Industry certifications like Greenroads and partnerships driving these changes are also covered.

Contents

- Introduction to Asphalt Sustainability and Road Safety

- Key Asphalt Sustainability Initiatives

- Safety Enhancements Through Sustainable Asphalt Practices

- Recycling and Reclamation in Asphalt Roads

- Environmental Benefits Of Sustainable Asphalt

- Certifications and Industry Collaboration

- Frequently Asked Questions (FAQ)

- Closing Thoughts

- Useful References for You:

Introduction to Asphalt Sustainability and Road Safety

Modern road construction blends eco-conscious methods with safety-first designs. Asphalt sustainability focuses on cutting environmental impact while building roads that last longer and perform better. This dual approach tackles climate concerns and creates surfaces drivers trust.

Defining Asphalt Sustainability in Road Infrastructure

Sustainable asphalt combines recycled materials, energy-smart production, and durable engineering. Key practices include using 30-50% reclaimed asphalt pavement (RAP), switching to warm mix asphalt (WMA) requiring 40% less heating energy, and designing pavements to last 20+ years. Programs like Greenroads® certify projects meeting strict eco-standards for material sourcing and emissions control.

Advanced techniques like rubberized asphalt (containing 10-22% recycled tire crumb) and plastic-modified mixes repurpose waste while boosting pavement flexibility. These methods align with circular economy principles—diverting 90 million tons of asphalt from landfills annually in the U.S. alone.

Link Between Sustainable Practices and Safer Roads

Eco-friendly asphalt directly improves road safety. High-RAP mixes with polymer additives resist rutting and cracking, reducing pothole risks. WMA’s lower production temperatures (230-290°F vs 300-350°F for traditional mixes) create smoother surfaces with better compaction—critical for tire grip during rain.

Noise-reducing open-graded friction courses (OGFC) cut traffic sound by 3-5 decibels, minimizing driver fatigue. Winter-ready asphalt mixes with cellulose fibers prevent freeze-thaw damage, while stone-matrix asphalt (SMA) designs enhance skid resistance. Each innovation shows how green choices make roads more reliable.

These foundational concepts set the stage for exploring specific techniques reshaping how we build and maintain transportation networks. Next, we’ll break down the key initiatives driving this transformation.

Key Asphalt Sustainability Initiatives

Innovative methods in road construction prioritize both eco-friendly methods and improved safety. Below are core practices reshaping the industry.

Recycled Material Integration in Asphalt Production

Using recycled components cuts resource use while boosting pavement performance. Two methods dominate this space.

Reclaimed Asphalt Pavement (RAP) Utilization

RAP reuses existing pavement materials, with mixes containing 20-30% RAP becoming standard. This method slashes material costs by $2–$5 per ton and lowers mining needs by 15%. PG binders (performance-graded polymers) ensure compatibility between old and new materials, preventing cracks.

| RAP Content | Benefits |

|---|---|

| 20% | Reduces CO₂ by 12% |

| 30% | Cuts costs by 18% |

Recycled Tire Rubber and Plastic Modifications

Crumb rubber from tires (CRM) and recycled plastics enhance flexibility and skid resistance. Blending 5% CRM into mixes lowers road noise by 3–5 decibels. Over 40 million tires are reused yearly in U.S. roads, diverting waste from landfills.

Warm Mix Asphalt (WMA) Adoption

WMA technologies lower production temps by 50°F versus traditional hot mixes. This shift drives multiple benefits.

Reducing Energy Consumption During Production

WMA requires 20% less fuel, saving 3–4 gallons per ton. Plants operating at 275°F instead of 325°F cut energy use by 35%, lowering production costs.

Lower Emissions for Safer Work Environments

Reduced temps decrease fumes by up to 50%, improving site visibility and worker health. Nitrogen oxide emissions drop by 30%, meeting stricter EPA standards.

Energy-efficient Asphalt Production Techniques

Modern plants prioritize smarter operations and cleaner fuels.

Optimized Plant Operations and Fuel Alternatives

Bio-based fuels like reclaimed oil cut CO₂ by 25%. Solar-powered drum dryers and geothermal heating systems reduce grid reliance. Plants using these methods report 12% lower operating costs.

Durable Pavement Design for Longevity

Longer-lasting roads mean fewer repairs and less resource use over time.

Enhancing Road Durability to Minimize Repairs

Superpave mix designs (performance-based specs) increase lifespan by 30%. Polymer-modified binders resist rutting and thermal cracking, extending service life to 20+ years. Thicker base layers (8–12 inches) further prevent structural failures.

These methods show how eco-friendly methods directly contribute to safer driving surfaces. Next, we’ll explore how specific pavement features boost traction and weather resistance.

Safety Enhancements Through Sustainable Asphalt Practices

Modern asphalt sustainability initiatives focus on boosting road safety while cutting down on resource consumption. By prioritizing mix innovation and material science, roads gain traits that protect both motorists and our surroundings.

Improved Surface Texture for Vehicle Traction

High-friction surfaces built with sustainable asphalt slash stopping distances by up to 30%. Mix designs using polymer-modified binders or crushed aggregates from recycled concrete create optimal microtexture. This boosts skid resistance, particularly during rain. A 2023 study found roads with such textures cut wet-weather crashes by 22% compared to traditional pavements.

Noise-reducing Asphalt for Safer Driving Conditions

Open-graded mixes containing 15-20% recycled tire rubber trim traffic noise by 3-5 decibels—similar to doubling a car’s distance from listeners. Quieter roads improve driver focus and lower accident risks linked to auditory fatigue. Arizona’s rubberized asphalt program reported a 40% drop in noise complaints on upgraded highways since 2018.

Weather-resistant Mixes to Prevent Cracking

Blends with 30-50% RAP and additives like basalt fibers withstand temperature swings from -20°F to 120°F. Such durability minimizes cracks that form hazards like potholes. PG 76-22 binders—common in northern climates—retain flexibility at 22°F, stopping frost-related damage. Michigan roads built with these mixes now last 14 years vs. 9 years for standard asphalt.

With roads now acting as both infrastructure and safety tools, material reclamation takes center stage. Next, we’ll look at how full-depth recycling turns aging pavements into strong foundations for tomorrow’s thoroughfares.

Also See: Guidelines for Regular Asphalt Maintenance

Recycling and Reclamation in Asphalt Roads

Cutting-edge recycling methods transform how asphalt roads get built. These asphalt sustainability initiatives slash waste while creating safer surfaces that last longer.

Full-depth Reclamation for Reduced Waste

Full-depth reclamation (FDR) reuses 100% of existing road materials. Heavy machinery pulverizes worn asphalt and base layers, blending them into a fresh foundation. Adding stabilizers like cement, lime, or foamed asphalt strengthens the mix for new pavement.

- Eliminates hauling costs for old materials

- Reduces project costs by 30-50% compared to traditional methods

- Improves load-bearing capacity with 20-30% RAP integration

FDR creates roads with fewer potholes and cracks – critical for asphalt road safety. A Michigan DOT study found FDR-treated highways lasted 12 years without major repairs.

Closed-loop Material Reuse Systems

Advanced plants now operate zero-waste systems. Crushed asphalt gets heated at 300°F in parallel drum mixers, reactivating the binder for new batches. Sensors track material flow to maintain mix quality while recycling 95% of plant byproducts.

- 25% less CO₂ emissions vs. virgin asphalt production

- 40% cost drop in road maintenance budgets

- ASTM D7762 standards ensure recycled mixes meet skid-resistance targets

Phoenix’s Loop 202 project used closed-loop systems to recycle 82,000 tons of pavement. The result? A 15% smoother ride with 60% less glare during night driving.

These asphalt sustainability practices prove eco-friendly methods boost both performance and protection. Next, we’ll examine how these gains translate into measurable planetary benefits.

Environmental Benefits Of Sustainable Asphalt

Modern asphalt sustainability practices cut environmental harm while boosting road safety. These methods tackle climate challenges head-on, merging material science with eco-friendly strategies.

Lower Carbon Footprint Via Reduced Energy Use

Warm Mix Asphalt (WMA) slashes production temperatures by 50–100°F compared to traditional hot mix. Lower heat means 20% less fuel burned and 15% fewer CO₂ emissions per ton. Plants using WMA technologies—like foaming or chemical additives—trim yearly greenhouse gases by 1.2 million metric tons in the U.S. alone. Pair this with energy-efficient drum plants running on biofuels, and carbon footprints shrink further.

| Practice | Energy Saved | CO₂ Reduction |

|---|---|---|

| WMA Adoption | 20-30% | 1.2M metric tons/year |

| RAP Integration | 22% per 25% RAP | 18% per ton |

Minimizing Landfill Waste Through Recycling

Reclaimed Asphalt Pavement (RAP) reuse hit 100 million tons annually in the U.S., diverting 95% of old roads from landfills. Adding recycled tire rubber—12 million tires yearly—or plastic modifiers like PET boosts durability while repurposing waste. A 30% RAP mix cuts raw material costs by $8–$12 per ton, proving eco-friendly asphalt isn’t just greener—it’s smarter economics.

| Material | Annual Waste Diverted | Use in Asphalt |

|---|---|---|

| RAP | 100M tons | Up to 40% of mix |

| Tire Rubber | 12M tires | 5-10% of binder |

These sustainability initiatives asphalt roads depend on are reshaping infrastructure. Next, certifications like Greenroads and industry partnerships ensure these gains become standard practice.

Certifications and Industry Collaboration

Groups now set clear rules to make asphalt roads green and safe. These steps ensure mixes meet high marks for both earth care and road strength.

Eco-friendly Asphalt Certification Programs

Programs like Greenroads check if asphalt meets eco goals. They ask for 20-30% reused stuff like RAP in new roads. Some also add rubber from old tires. Builders who pass get LEED points for city jobs. Such steps cut plant fumes by 40% and boost road life by 50%.

Collaborative Research for Sustainable Standards

Big groups like NAPA and FHWA team up to test new ideas. Their work shows warm mix asphalt cuts CO2 by 15%. The Asphalt Institute tracks road wear to find blends that last. Shared data helps all builders use green tech faster.

These joint efforts pave the way for key questions on asphalt’s next eco steps.

Frequently Asked Questions (FAQ)

How Can We Improve the Sustainability Of Asphalt?

Improving the sustainability of asphalt can involve incorporating higher percentages of recycled materials, utilizing warm mix asphalt technologies, and implementing energy-efficient production techniques. Additionally, promoting durable design solutions that extend road life can help reduce the frequency of repairs and the associated environmental impacts.

What Makes Asphalt an Environmentally Friendly Choice?

Asphalt is considered environmentally friendly due to its high recyclability, with crushed asphalt being reused to produce new pavement. The material’s production can also be optimized to reduce energy consumption and greenhouse gas emissions. Furthermore, innovations such as warm mix asphalt and the integration of recycled rubber and plastics contribute to its sustainability.

What Role Do Industry Organizations Play in Asphalt Sustainability?

Industry organizations play a crucial role in promoting sustainable practices through research, setting standards, and developing certification programs. They facilitate collaboration among stakeholders to share best practices, invest in innovative technologies, and advocate for policies that support sustainable asphalt production and road safety.

Closing Thoughts

Asphalt sustainability initiatives play a pivotal role in enhancing road safety while minimizing environmental impact. By incorporating recycled materials, adopting warm mix asphalt (WMA), and optimizing production techniques, the asphalt industry significantly reduces energy consumption and emissions. These practices not only improve durability and longevity but also enhance traction and decrease noise levels for safer driving conditions.

Moreover, efforts like full-depth reclamation and closed-loop systems demonstrate an ongoing commitment to waste reduction and resource efficiency. Certifications and collaboration among industry stakeholders drive continuous improvement, ensuring that roads meet modern sustainability demands.

By embracing these initiatives, we can pave the way for safer, more sustainable roadways. For further insights on asphalt sustainability and to explore more resources, check out Asphalt Calculator USA.

Useful References for You:

- Scientists Are Engineering Asphalt That Is Safer for Humans and the Environment – PMC

- 3 Ways Asphalt and Concrete Are Affecting the Planet | Aexcel

- The Benefits of Asphalt as a Sustainable Material When Constructing Pavements – Asphalt Materials, Inc.

- Sustainability promotion through asphalt pavements: A review of existing tools and innovations – ScienceDirect