Asphalt Heating Methods Compared: Which Works Best?

Published on: April 7, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Asphalt heating methods comparison evaluates tools like infrared heaters, propane torches, and electric blankets to identify optimal solutions for road repairs and installations. These techniques differ in heating speed (infrared reaches 300°F in 10 minutes vs. 30+ minutes for flame methods), fuel efficiency (electric mats use 15-20 kWh vs. propane’s 2-3 gallons/hour), and climate adaptability—infrared performs better in sub-40°F conditions than hot oil systems. Environmental impacts range widely, with electric options producing zero onsite emissions versus flame methods releasing 8-12 lbs CO2 per hour.

This guide analyzes eight heating approaches used in asphalt work. We’ll contrast traditional torch-down methods with infrared reheaters for driveway patching, including cost data (infrared units cost $2,800-$5,000 vs. $200 for propane kits). Explore why hot box heaters dominate highway projects but waste 15-20% more material. Discover how heating precision affects pavement longevity—infrared maintains ±5°F control versus ±25°F swings in flame systems. Get climate-specific tips, safety protocols, and efficiency metrics to pick your best method.

Contents

- Introduction to Asphalt Heating Techniques

- Key Methods Of Heating Asphalt

- Comparing Asphalt Heating Methods for Driveways

- Efficiency and Performance Analysis

- Material Properties and Heat Dynamics

- Cost Comparison Of Heating Techniques

- Environmental Impact Of Heating Methods

- Common Questions About Asphalt Heating

- Closing Thoughts

- Additional Resources for You:

Introduction to Asphalt Heating Techniques

What is Asphalt Heating?

Heating asphalt modifies its physical state for paving or repair work. This process softens the material, letting crews shape, compact, or bond new layers. Common methods include flame heating, infrared systems, electric blankets, and hot oil units. Each technique targets specific needs—from fixing cracks on driveways to laying fresh pavement on highways.

Why Proper Heating Matters for Asphalt Performance

Correct heating ensures the mix reaches the right viscosity for compaction. If temps drop below 275°F, bonding weakens. Overheating above 325°F burns the binder, creating brittle surfaces prone to cracks. Proper thermal control during heating boosts longevity by up to 30% in high-traffic zones.

Techniques like infrared heating deliver even heat distribution, minimizing cold spots. Traditional torch methods might save time but risk scorching the surface. Selecting the best method balances speed, cost, and structural integrity.

With the basics covered, let’s examine the tools and technologies driving modern asphalt heating.

Key Methods Of Heating Asphalt

Selecting the right asphalt heating method affects project success. Options range from decades-old flame systems to advanced electric solutions. Each technique has unique strengths tied to specific repair needs.

Traditional Asphalt Heating Methods

Older approaches rely on direct heat application. These methods work best for small-scale repairs but require careful handling.

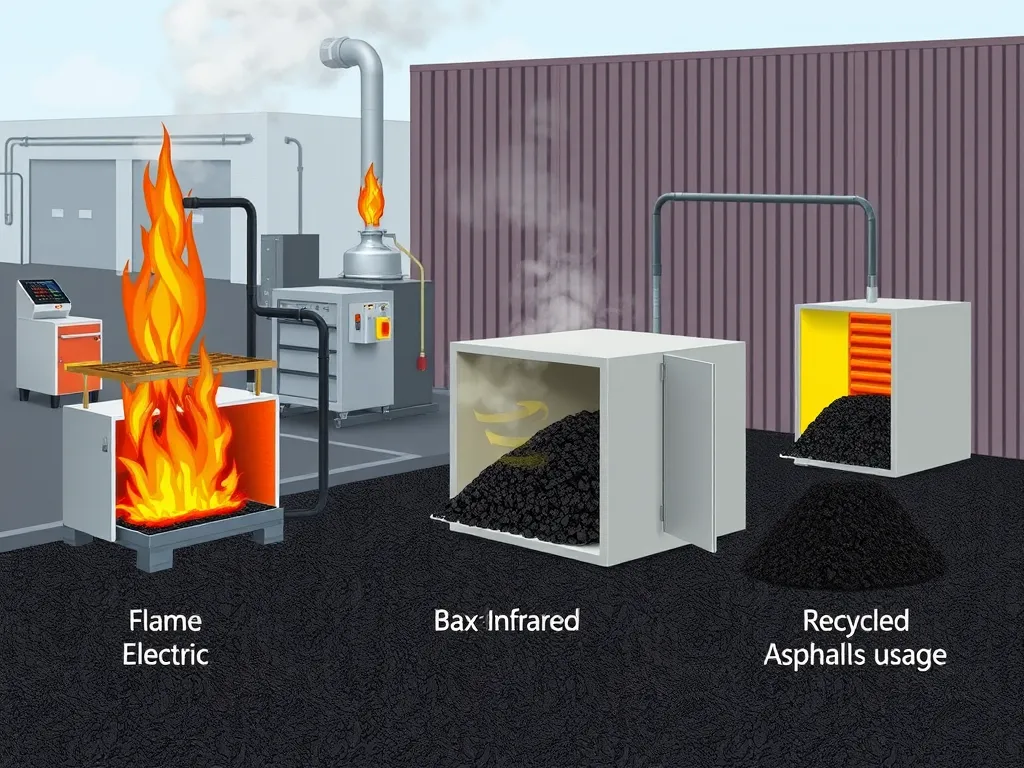

Flame Heating (Torch Down)

Open-flame propane torches heat asphalt at 300-400°F. Workers manually direct flames to soften surfaces before patching. Flame heating costs $25-$50 per hour in fuel but risks scorching materials. Used for crack sealing on roads or driveways.

Hot Oil Heating Systems

Thermal oil circulates through pipes to transfer heat evenly. Maintains temps up to 350°F without direct contact. Hot oil systems handle large parking lots but need 8-12 hours to preheat. Setup costs exceed $15,000 for commercial units.

Propane Torch Applications

Portable torches apply spot heat to damaged areas. Operates at 500-700 BTU/hour for quick fixes like potholes. Limited to surface-level repairs due to uneven penetration. Fuel costs average $3-$5 per square foot.

Modern Asphalt Heating Techniques

Newer methods prioritize energy efficiency and precise control. These options reduce labor while boosting temperature accuracy.

Infrared Heating Technology

Electromagnetic waves penetrate 2-3 inches deep without open flames. Infrared panels heat 100 sq ft in 8-10 minutes at 85% efficiency. Units range from $8,000 (small) to $40,000 (industrial). Eliminates fumes but struggles with thick overlays.

Electric Heating Mats and Blankets

Flexible mats apply 150-200°F heat through embedded coils. Covers up to 200 sq ft with 1-hour warm-up cycles. Electric models cut emissions by 60% vs propane. Requires 240V power, costing $0.30-$0.50 per kWh.

Hot Box Asphalt Heaters

Mobile units reheat recycled asphalt to 325°F. Hot boxes hold 1-5 tons of material, using diesel burners or electric elements. Achieves 90% reuse rates for milled pavement. Daily rentals run $300-$800 plus fuel.

With core methods outlined, let’s examine how they perform on residential driveways.

Comparing Asphalt Heating Methods for Driveways

How to Heat Asphalt for Driveway Repairs

Driveway repairs demand precise heat application to reactivate the binder (bitumen) without damaging surrounding material. Propane torches work for small cracks but lack temperature control. Electric heating mats distribute heat evenly at 250-300°F, ideal for pothole patches under 10 sq.ft. For larger areas like alligator cracks, portable hot box heaters maintain asphalt at 325°F for seamless bonding. Always measure surface temps with a laser thermometer to stay below 350°F—the scorching threshold.

Infrared Vs. Electric Heating for Residential Use

IR (infrared) systems use radiant panels to heat asphalt surfaces rapidly—up to 1 inch deep in 8-10 minutes. They excel at repairing utility cuts or driveways with minimal disruption. Electric blankets operate slower (30-45 minutes for 2-inch depth) but offer exact temperature modulation via digital controllers. For residential jobs under 50 sq.ft., electric methods average $12-$18 per hour in energy costs. IR units require higher upfront investment ($1,800-$3,500) but complete repairs 3x faster.

Safety Considerations for Driveway Applications

Open-flame propane torches pose fire risks near landscaping or garage doors. Electric systems eliminate open combustion but require GFCI-protected outlets to prevent shocks. Always wear heat-resistant gloves and ANSI-rated eyewear. For IR repairs, mark heated zones with chalk to avoid accidental contact with 400°F surfaces. Never leave equipment unattended—asphalt can ignite at 500°F+.

Evaluating energy efficiency and temperature control helps determine the best approach for specific projects.

Also See: Asphalt Waste Management Strategies: Eco-friendly Solutions

Efficiency and Performance Analysis

Selecting the right method to heat asphalt requires balancing energy use, temperature precision, and environmental conditions. Performance metrics vary widely between systems, directly impacting project timelines, costs, and longevity.

Energy Consumption Across Methods

Flame heating with propane torches consumes 500,000–700,000 BTUs per hour, while infrared systems use 30–50% less fuel. Electric mats draw 2–5 kW per square yard, relying on grid sources. Hot oil heaters powered by diesel burn 4–6 gallons hourly. Solar-powered infrared units reduce fossil fuel dependency by 80% in sunny regions.

Heating Capacity and Temperature Control

Infrared radiators reach 300°F within 10 minutes, ideal for spot repairs. Hot oil systems maintain ±5°F accuracy for large-scale jobs. Electric blankets heat slower (1–2 hours to 200°F) but prevent scorching. Flame-based methods risk uneven heating, with surface temps spiking beyond 400°F if unchecked.

Effectiveness in Cold Vs. Warm Climates

Below 40°F, infrared outperforms electric systems by minimizing thermal loss. Propane torch down requires 20% more fuel in freezing temps to sustain bonding. In hot climates, electric mats prevent overheating, while flame methods demand frequent cooling pauses. Moisture from thawing reduces adhesion by up to 35% if heating isn’t uniform.

Evaluating thermal behavior leads naturally to examining material science behind heat retention. Next, we’ll break down how asphalt’s composition influences these outcomes.

Material Properties and Heat Dynamics

Thermal behavior directly impacts the success of heating techniques. Let’s explore how composition influences heat transfer in paved surfaces.

Asphalt Vs. Concrete: Heat Absorption Comparison

Asphalt’s dark color gives it lower solar reflectance (albedo 0.05-0.10) versus concrete (0.20-0.35). This difference means paved surfaces reach higher temps: 120-150°F for asphalt versus 100-115°F for concrete on sunny days. Higher heat retention requires less energy input during repairs using methods like infrared heating. But concrete’s lower thermal conductivity (0.8-1.3 W/mK) slows heat penetration compared to asphalt (1.5-2.0 W/mK).

Does Asphalt Act As a Heat Insulator?

While paved surfaces store heat, they don’t block thermal transfer effectively. Asphalt’s thermal resistance (R-value 0.03-0.05 per inch) falls short of true insulators like fiberglass (R-3.7 per inch). This limits its ability to retain heat during methods like torch-down applications. Contractors compensate by maintaining steady temps via electric mats or hot box systems. Rapid cooling risks incomplete bonding in patch jobs.

Grasping these dynamics sets the stage for evaluating cost factors linked to energy use. Next, we’ll break down expenses tied to each method.

Cost Comparison Of Heating Techniques

Upfront Equipment Costs

Flame heating gear runs $500-$2,000 for torches and tanks. Hot oil systems cost $5,000-$15,000 due to boilers and pumps. Propane torch setups are cheaper at $200-$800. Modern asphalt heating techniques like infrared panels start at $3,000-$12,000. Electric mats or blankets range $1,500-$5,000. Hot box heaters, built for big jobs, hit $8,000-$25,000.

Key upfront spend factors:

- Flame/hot oil: Low to mid-range costs

- Infrared/electric: Higher initial buy-in

- Hot box: Top-tier price for heavy use

Long-term Operational Expenses

Flame methods burn 10-20 gallons of propane per job ($3/gal). Hot oil systems use 5-10 gallons of fuel oil daily ($4/gal). Electric mats draw 30-50 kWh per use ($0.15/kWh avg). Infrared cuts fuel use by 20-40% vs flame. Hot boxes eat 2-4 gallons of diesel per hour but handle 5+ tons of mix.

Hidden costs add up:

- Flame: High fuel spend, more labor hours

- Electric: Low upkeep, no fuel storage

- Infrared: Quick reuse cuts repave time 50%

Recycled asphalt (RAP) use with infrared or hot box trims material costs by 25%.

Costs tie tight to green perks. Next, we break down how each method impacts air, soil, and reuse rates.

Environmental Impact Of Heating Methods

Heating asphalt affects air quality and energy use. The choice between flame, electric, or infrared changes carbon footprints. Let’s break down key factors.

Emissions From Combustion-based Techniques

Propane torches and flame heating release CO2, NOx, and particulate matter. A propane torch emits 8-12 lbs of CO2 per gallon burned. Hot oil systems leak fumes with sulfur compounds in older models. These methods also waste heat – up to 30% escapes unused. Workers face health risks from direct exposure to fumes.

Sustainability Of Electric and Infrared Options

Electric mats cut emissions by 60-80% vs propane when using grid power. Solar or wind energy drops this to near zero. Infrared heating uses targeted waves to warm asphalt without open flames. It slashes fuel use by half in tests. Both methods recycle heat better – infrared retains 85% energy in the surface. Upfront costs run higher, but lower upkeep and tax credits offset this over 5-7 years.

Next, we’ll weigh cash costs – from gear prices to yearly bills – for each asphalt heating technique.

Common Questions About Asphalt Heating

How to Heat an Asphalt Driveway Effectively?

To heat an asphalt driveway effectively, select a method that allows for even heat distribution without damaging the surrounding material. Common options include propane torches for small areas and infrared systems or electric heating mats for larger patches. Always monitor temperatures to ensure they remain within the safe range of 250°F to 325°F to avoid scorching the surface. Remember to use a laser thermometer to check the surface temperature accurately.

Which Absorbs More Heat: Asphalt or Concrete?

Asphalt generally absorbs more heat than concrete due to its darker color and lower solar reflectance properties. Asphalt typically achieves surface temperatures of 120-150°F on sunny days, compared to 100-115°F for concrete. This heat retention characteristic allows asphalt to require less energy for repairs when utilizing heating methods.

Can Asphalt Be Overheated During Repairs?

Yes, asphalt can be overheated during repairs. Exceeding temperatures of 325°F can burn the asphalt binder, leading to a brittle surface that is prone to cracking. It’s essential to maintain appropriate heating intervals and monitor temperature closely, especially when using flame-based heating methods that can quickly spike heat levels.

Closing Thoughts

Choosing the right asphalt heating method is vital for achieving optimal performance and longevity in your projects. From traditional techniques like flame heating and hot oil systems to modern approaches such as infrared and electric options, each method has unique benefits and drawbacks. Understanding these can help you make informed decisions based on your specific needs, whether it’s for residential driveways or larger commercial applications.

Consider factors like energy efficiency, heating capacity, and environmental impact when selecting a method. For instance, infrared heating offers great precision but may come at a higher initial cost compared to traditional methods. Always weigh these elements against your project’s budget and objectives.

For ongoing insights and tools to assist with your asphalt projects, visit Asphalt Calculator USA. Whether you’re a DIY enthusiast or a professional contractor, we provide valuable resources to guide your asphalt heating choices.

Additional Resources for You:

- A review on the heat transfer in asphalt pavements and urban heat island mitigation methods – ScienceDirect

- Thermal performance of cooling strategies for asphalt pavement: A state-of-the-art review – ScienceDirect

- Heat Exchanger vs. Asphalt Heater for Asphalt Applications – Enerquip Thermal Solutions

- Thermal Behavior of an Asphalt Pavement in the Laboratory and in the Parking Lot – PMC