Asphalt Energy Efficiency in Construction

Published on: June 23, 2025 | Last Updated: April 14, 2025

Written By: George Voss

Asphalt energy efficiency in construction means building roads and pavements using methods that slash energy use. This starts with warm-mix asphalt (WMA) requiring 50-100°F less heat than traditional mixes, cutting plant fuel use by 20%. It extends to high-reflectance surfaces that lower urban temperatures by up to 7°F and recycling methods reusing 95% of old pavement. These steps maintain durability while shrinking energy footprints.

This article breaks down how asphalt outperforms other materials in energy-smart construction. We’ll compare production energy against concrete, explain how reflective coatings reduce cooling costs, and share real-world data on recycling savings. You’ll get actionable strategies like using reclaimed asphalt pavement (RAP) and tools like the Federal Highway Administration’s PaLATE software for tracking energy impacts.

Contents

- The Role Of Asphalt in Energy-efficient Construction

- Energy-efficient Characteristics Of Asphalt

- Energy Requirements for Asphalt Production

- Best Practices for Optimizing Asphalt Energy Efficiency

- Benefits Of Energy-efficient Asphalt Pavements

- Case Studies in Energy-efficient Asphalt Implementation

- Environmental Considerations for Asphalt Efficiency

- Frequently Asked Questions

- Closing Thoughts

- Useful References for You:

The Role Of Asphalt in Energy-efficient Construction

Used in over 94% of paved roads nationwide, asphalt dominates modern infrastructure due to its blend of performance traits. Beyond structural strength, its role in curbing energy use during construction forms the bedrock of sustainable development.

Importance Of Asphalt in Construction Projects

From highways to bike paths, asphalt’s flexibility makes it ideal for diverse projects. Its capacity to handle heavy loads without cracking minimizes repair cycles, directly lowering lifetime energy inputs. Properly designed mixes meet exact climate needs through PG (Performance Graded) binders, boosting reliability while cutting resource waste.

Durability and Long-Term Performance

High-quality asphalt pavements survive 15-20 years before major rehabilitation. Innovations like polymer-modified binders extend service life by 30% compared to conventional mixes. This longevity reduces reconstruction frequency, slashing embodied energy linked to material extraction, transport, and installation by up to 35% over three decades.

Reducing Maintenance Energy Consumption

Less frequent repairs translate to lower fuel consumption for machinery. For every mile of road maintained yearly, asphalt requires 40% fewer work hours than concrete. Recycling during upkeep—reusing 99% of milled material—shrinks energy demand by 20% versus virgin production. This closed-loop process keeps tons of debris from landfills, further shrinking carbon footprints.

With these benefits in mind, let’s explore how specific properties of asphalt enhance its energy-saving potential.

Energy-efficient Characteristics Of Asphalt

Asphalt stands out for traits that cut energy use in roads, lots, and builds. Its makeup and design boost eco gains while meeting tough build needs.

Thermal Properties and Insulating Benefits

Asphalt traps heat well. This slows heat loss in cold months. Roads store warmth, cutting frost depth under slabs. Less frost means less risk of cracks from freeze-thaw cycles. For builds near pavements, this heat buffer can trim heating bills by up to 30% in winter. Dark color aids heat soak, which lowers snow plow fuel use by 15% versus light surfaces.

Light Reflectivity and Urban Heat Mitigation

New cool asphalt mixes fight urban heat islands. These blends use high-albedo coats that bounce 30% more sun rays than standard blacktop. Tests show temps drop 7°F on roads with these surfaces. Lower temps cut AC demand in nearby shops and homes. Some cities now set reflect rules for lots to meet green codes.

Life Cycle Analysis Of Asphalt Pavement Efficiency

Life cycle studies track asphalt’s energy wins from mine to mile. Key finds:

| Phase | Energy Use (GJ/ton) | Eco Gain |

|---|---|---|

| Make | 1.2 | Recycled saves 20% |

| Lay | 0.8 | Warm-mix cuts 35% |

| Use | 0.3/year | Smooth roads save fuel |

Over 20 years, asphalt beats concrete by 18% in total energy spend. Its reuse rate hits 95%, slashing mine and haul needs.

These traits shape how teams pick builds that save fuel, time, and cash. Next, we break down the energy math behind making asphalt mixes.

Energy Requirements for Asphalt Production

Producing asphalt requires balancing heat inputs with material science. The process uses 20-30% less energy per ton than concrete manufacturing. Key factors include aggregate heating temperatures, binder types, and plant fuel sources.

Breaking Down the Manufacturing Process

Asphalt plants heat aggregates to 275-325°F before mixing with liquid bitumen. Modern plants cut energy use through:

- High-efficiency burners (reducing fuel needs by 15%)

- Warm-mix additives lowering mixing temps by 50°F

- Recycled asphalt pavement (RAP) integration up to 30%

PG (Performance-Graded) binders allow precise temperature control, trimming 8-12% energy per batch.

Comparison with Alternative Materials

Concrete demands 1500°F kiln temperatures for cement production – six times hotter than asphalt mixing. Steel-reinforced pavements add 40% more embodied energy from material extraction. Asphalt’s faster curing also cuts construction-phase fuel use by 25% compared to concrete’s 7-day setting period.

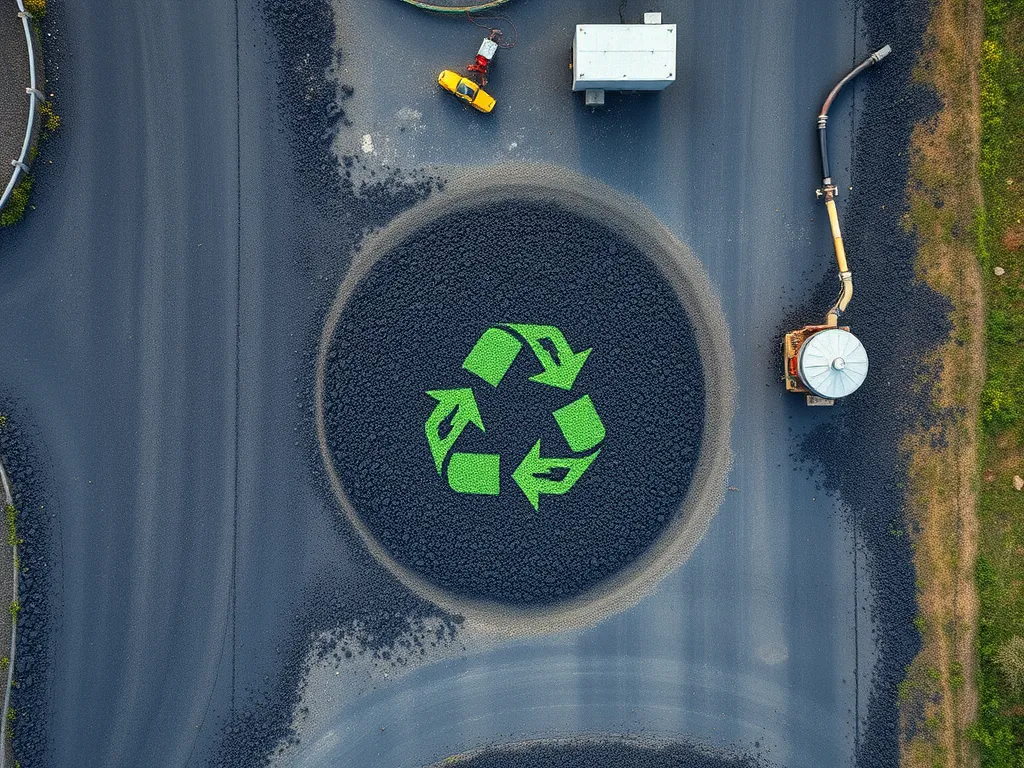

Recyclability and Reduced Energy Demand

Recycling asphalt slashes energy needs by 20% per mile. RAP reuse avoids reheating virgin aggregates, saving 350,000 BTU per ton. The National Asphalt Pavement Association reports 94% U.S. asphalt gets recycled – diverting 72 million tons from landfills yearly.

Cold recycling techniques require 60% less fuel than traditional hot-mix methods. Projects using 50% RAP mixtures save $2-5 per ton while maintaining pavement energy efficiency ratings above 85%.

Upgrading production methods and recycling rates directly impacts the energy performance of asphalt pavements. Next, we’ll examine strategies to maximize these gains during installation.

Also See: The Role Of Asphalt in Airport Construction

Best Practices for Optimizing Asphalt Energy Efficiency

Implementing energy-saving methods in road projects requires precise material choices, modern methods, nd tech-driven tools. Let’s explore proven strategies.

Material Selection and Mix Design Strategies

High RAP (Reclaimed Asphalt Pavement) blends cut production energy by 20% while maintaining structural integrity. PG (Performance-Graded) binders tailored to local climates minimize thermal cracking risks, extending service life. Polymer-modified mixes boost rut resistance, lowering long-term repair needs by up to 35%.

Energy-efficient Paving Techniques

Infrared thermal profiling ensures uniform heat distribution during placement, reducing fuel use. Intelligent compaction systems with GPS mapping cut roller passes by 30%, slashing diesel consumption.

Warm-Mix Asphalt Applications

| Parameter | WMA | HMA |

|---|---|---|

| Production Temp | 230-275°F | 300-350°F |

| Fuel Use | 15-20 gal/hr | 22-28 gal/hr |

| CO₂ Emissions | 30% Less | Baseline |

Warm-mix technologies like foaming or chemical additives enable workability at lower temps. Projects report 12-15% energy savings versus traditional hot-mix methods.

Tools for Calculating Asphalt Energy Efficiency

Life cycle assessment (LCA) software quantifies embodied energy from extraction to disposal. The Federal Highway Administration’s INVEST tool tracks 22 sustainability metrics for pavement projects.

Software and Measurement Frameworks

PaLATE 2.0 computes energy inputs per ton of mix, while BEES 5.0 compares options using ISO 14040 standards. These platforms help teams select mixes with 8-10% lower carbon footprints without compromising load-bearing capacity.

With these methods in place, the next section explores how optimized practices translate into measurable cost benefits for cities and contractors.

Benefits Of Energy-efficient Asphalt Pavements

Energy-efficient asphalt pavements deliver measurable advantages across construction projects and infrastructure lifespans. These benefits span financial savings, environmental impact reduction, and improved structural performance.

Cost Savings Through Reduced Energy Consumption

Energy-efficient asphalt pavement directly lowers operational costs. Warm-mix asphalt technologies reduce production temperatures by 50°F compared to traditional hot-mix methods, cutting fuel consumption by 20%. Recycling practices amplify savings: reclaimed asphalt pavement (RAP) reuse rates exceed 90% in projects, slashing material costs by $3–$5 per ton. Over a 30-year lifecycle, energy-efficient designs reduce road maintenance energy demands by 35%, minimizing equipment fuel use and labor hours.

Enhanced Load Distribution and Fuel Efficiency

Asphalt’s flexible pavement structure improves load distribution, reducing stress on roadbeds by 40–60% compared to rigid concrete. This design lowers deflection under heavy vehicles, boosting fuel efficiency for trucks by 2–4% according to National Asphalt Pavement Association studies. Smoother asphalt surfaces also cut rolling resistance, improving passenger vehicle fuel economy by 4–7% per Federal Highway Administration data. Strategic thickness designs using AASHTOWare Pavement ME further optimize load-bearing efficiency.

These advancements position asphalt as a leader in sustainable infrastructure. Next, we’ll examine real-world projects demonstrating these principles in action.

Case Studies in Energy-efficient Asphalt Implementation

Real-world projects show how asphalt construction energy efficiency translates to measurable results. From highways to parking lots, innovative techniques cut energy use while boosting pavement performance.

Highway Infrastructure Success Stories

The Federal Highway Administration’s 2022 report highlights Texas’ I-35 rebuild using warm-mix asphalt (WMA) at 250°F instead of traditional 300°F mixes. This cut fuel consumption by 30% during production, saving $1.2M in energy costs across 150 lane-miles. Nevada’s Route 50 project incorporated 40% recycled asphalt pavement (RAP), reducing virgin material needs by 18,000 tons and lowering CO2 emissions by 1,800 metric tons.

Minnesota DOT’s TH-61 expansion used energy-efficient asphalt pavement with high-albedo aggregates. Post-construction thermal scans showed 12°F lower surface temps versus conventional mixes, decreasing urban heat island effects. The design extended service life to 22 years, slashing maintenance energy by 35% over two decades.

Urban Parking Lot Optimization Projects

Phoenix’s Desert Ridge Mall installed porous asphalt with 23% air voids, eliminating stormwater pumps and cutting irrigation energy by 400 kWh/month. Infrared reflectance tests showed a solar reflectance index (SRI) of 38, 15 points higher than standard lots, reducing nighttime cooling loads for adjacent buildings.

Chicago’s Wacker Drive retrofit used energy-efficient asphalt pavement with 25% steel slag aggregates. Thermal imaging confirmed 9°F lower temps during summer peaks, shrinking AC demand for nearby offices by 18%. The project recycled 95% of existing pavement, diverting 6,500 tons from landfills and saving 2.1 million BTU in material production.

These projects prove that life cycle analysis asphalt pavement strategies work at scale. From mix design to installation, every choice impacts energy performance of asphalt pavements – a critical factor as cities face tighter climate targets.

Next, we’ll examine how environmental considerations shape modern asphalt efficiency standards beyond project-level gains.

Environmental Considerations for Asphalt Efficiency

Balancing pavement performance with environmental stewardship requires targeted strategies. Focused efforts on lowering embodied energy and adopting green maintenance methods can cut asphalt’s footprint while maintaining structural integrity.

Reducing Embodied Energy in Road Construction

Embodied energy refers to total energy consumed during material extraction, production, and transport. Asphalt’s embodied energy averages 0.11 kWh per pound – 25% lower than concrete. Using recycled asphalt pavement (RAP) slashes this further. Projects with 40% RAP content reduce energy demands by 34% compared to virgin mixes.

| RAP Content | Energy Reduction |

|---|---|

| 20% | 18% |

| 30% | 26% |

| 40% | 34% |

Warm-mix asphalt (WMA) tech also plays a role. WMA production temps run 30-50°F cooler than traditional hot-mix, trimming fuel use by 20-35%. Pairing WMA with RAP creates pavements needing 40% less energy per lane-mile.

Eco-friendly Maintenance Approaches

Proactive maintenance extends pavement life while minimizing resource use. Infrared patching repairs potholes at 50% lower energy cost than full-depth replacements. Microsurfacing – applying polymer-modified emulsion layers – uses 40% less binder and 60% fewer aggregates than overlays.

Permeable asphalt systems tackle stormwater management without separate drainage infrastructure. These pavements filter 500 gallons of water per square yard annually, cutting energy used for pumping and treatment by up to 18% in urban areas.

These strategies show how asphalt construction energy efficiency ties directly to operational choices. Next, we’ll examine real-world projects proving these concepts work at scale.

Frequently Asked Questions

What Are the Environmental Benefits Of Using Asphalt in Construction?

Asphalt provides significant environmental advantages, including lower embodied energy compared to concrete, and it supports sustainable practices through high recycling rates of materials. Its reflective properties can aid in reducing urban heat island effects, contributing to cooler city environments.

How Does Recycling Asphalt Contribute to Energy Efficiency?

Recycling asphalt significantly reduces energy demand, as it eliminates the need for energy-intensive processes associated with virgin material extraction and processing. By reusing materials, projects can save resources and minimize environmental impact, resulting in up to 20% energy savings per mile of paved surface.

What is Warm-mix Asphalt and How Does It Improve Energy Efficiency?

Warm-Mix Asphalt (WMA) is produced at lower temperatures than traditional hot-mix methods, requiring 50°F less heating. This reduction in production temperature results in lower fuel consumption and decreased greenhouse gas emissions. Warm-mix technologies enhance workability while maintaining the strength and durability of asphalt pavements.

Are There Specific Standards or Certifications for Energy-efficient Asphalt Practices?

Yes, various standards and certifications, such as the Federal Highway Administration’s INVEST tool, evaluate the sustainability and energy efficiency of asphalt projects. These tools offer frameworks for measuring energy impacts, ensuring compliance with sustainability goals in pavement construction and renovation.

Closing Thoughts

Asphalt plays a vital role in enhancing energy efficiency in construction. Its durability extends the lifespan of pavements, minimizing the need for energy-intensive repairs. Not only does asphalt reduce energy costs throughout its life cycle, but its thermal properties significantly impact building energy performance. With advancements in warm-mix technology and an emphasis on recyclability, the industry moves towards even greater sustainability.

Implementing best practices can optimize asphalt’s energy efficiency, leading to substantial cost savings. From material selection to paving techniques, every decision counts in creating environmentally friendly infrastructures. The success stories across highways and urban developments prove that energy-efficient asphalt is not just a theory, but a practical solution.

For more insights and resources on asphalt energy efficiency, visit Asphalt Calculator USA.

Useful References for You:

- American Association of State Highway and Transportation Officials (AASHTO). (2008). Mechanistic-Empirical Pavement Design Guide (MEPDG). Washington, DC: AASHTO.

- Energy Consumption of Asphalt and Reinforced Concrete Pavement Materials and Construction | Request PDF

- How To Choose the Right Asphalt Paver for Your Project

- Improve Energy Efficiency Through Best Practices at Your Asphalt Plant | For Construction Pros

- Energy and Road Construction-What’s the Mileage of Roadway? – Pavement Interactive