Your Ultimate Asphalt tonnage calculator

Asphalt Tonnage Calculator

Estimate the exact quantity of asphalt needed for your paving project. Jump to How to Use

What is Asphalt Tonnage?

Asphalt tonnage refers to the total weight of asphalt (measured in tons) required to cover a specific area at a desired thickness. It’s calculated using the project’s dimensions (length, width, depth) and the density of the asphalt mix. Accurately determining tonnage ensures you order the right amount of material, avoid costly overages or shortages, and stay within budget. Our calculator simplifies this process, but manual formulas can also be used for smaller projects.

How to Calculate Asphalt Tonnage?

Accurately estimating asphalt tonnage is essential for budgeting and ensuring you order the right amount of material. While our asphalt tonnage calculator above provides instant, error-free results, understanding the manual calculation process helps you verify estimates or plan smaller projects. Below, we break down the formula and key variables—or skip the math and let our tool handle it for you!

Tonnage Formula:

(Length (ft) × Width (ft) × Depth (inches) / 12) × Asphalt Density (lbs/cu ft) / 2000

Example: A 50 ft × 20 ft driveway with 3-inch depth using Hot Mix Asphalt (145 lbs/cu ft):

(50×20×3/12) × 145 / 2000 = 18.1 tons

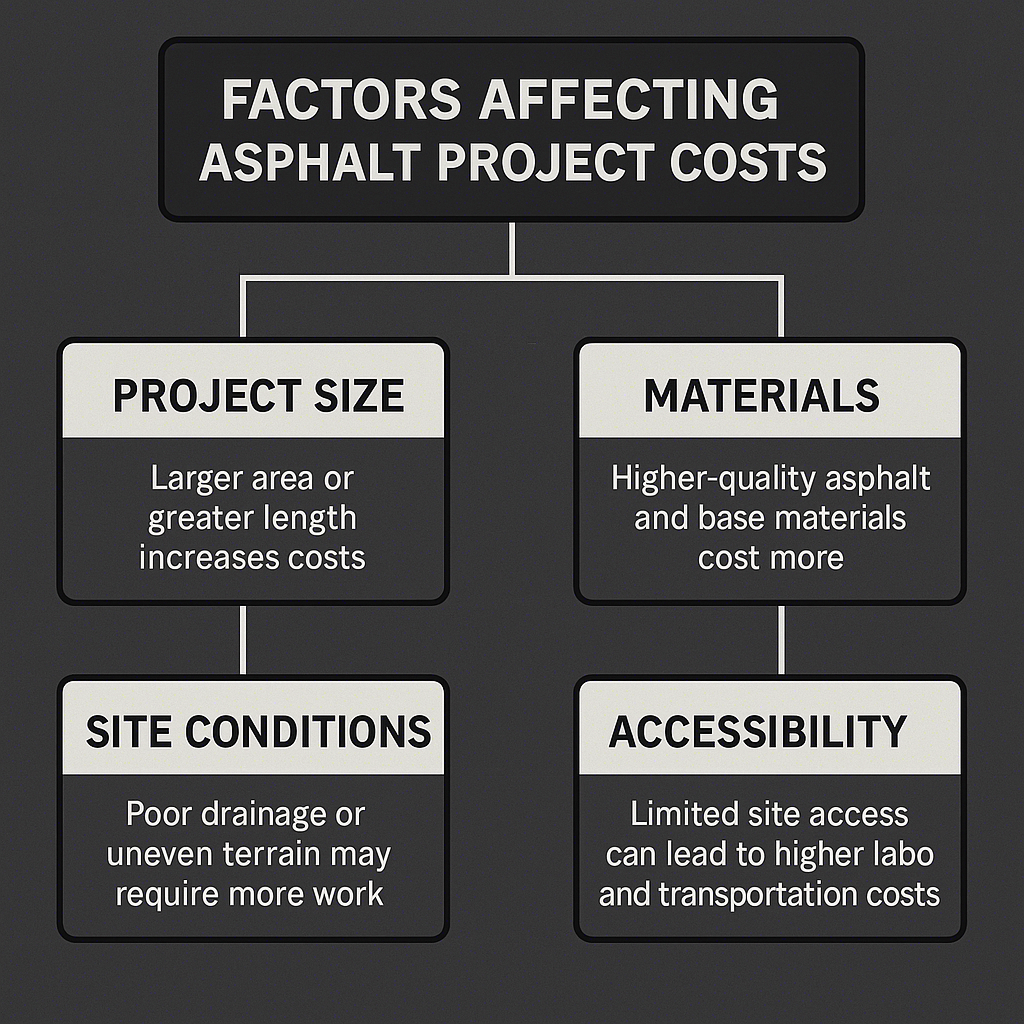

Factors Affecting Asphalt Tonnage Calculations

1. Project Dimensions

Your project’s length, width, and depth directly determine asphalt volume:

- Small Projects (Under 500 sq. ft.): 2-5 tons of asphalt

- Medium Projects (500-2,000 sq. ft.): ~12.5 tons for a 1,000 sq. ft. driveway

- Large Projects (Over 2,000 sq. ft.): Bulk pricing applies

2. Asphalt Type & Density

Different mixes have varying weights per cubic yard:

- Hot Mix Asphalt (HMA): 145 lbs/cu ft (most common)

- Cold Mix Asphalt: 135 lbs/cu ft (temporary repairs)

- Porous Asphalt: 125 lbs/cu ft (drainage-friendly)

3. Compaction & Site Conditions

Compacted asphalt requires 10-15% more material. Uncompacted volume: 100 cubic yards → 115 tons after compaction

4. Waste Allowance & Base Layers

- Waste: Add 5-10% extra asphalt for trimming

- Base Preparation: Gravel sub-base ($1.50-$3/sq. ft.) adds cost but improves longevity

How Does the Asphalt Tonnage Calculator Work?

An asphalt tonnage calculator estimates the material required based on project dimensions, compaction needs, and asphalt density. Users input details like length, width, thickness, and adjust for compaction and material type. The calculator combines these variables with industry-standard formulas to provide precise tonnage, helping users avoid over-ordering or under-ordering asphalt.

Step-by-Step Breakdown

Our asphalt tonnage estimator simplifies planning with a clear input process:

Enter Project Dimensions

- Length & Width: Measure the area to be paved (e.g., 50 ft x 10 ft for a driveway).

- Thickness: Specify the compacted asphalt depth in inches (e.g., 2-3 inches for residential driveways).

Adjust Compaction & Density

- Compaction Factor: Add 10-15% to account for material compression during installation.

- Asphalt Density: Standard hot mix asphalt uses ~145 lbs/ft³, but this varies by material type.

Calculate Tonnage

- The tool computes total cubic feet, adjusts for compaction, and converts to tons (1 ton = 2000 lbs).

- Results show both base tons and total tons (including waste allowance).

Example: “How much asphalt do I need for a 1,000 sq. ft. driveway?” or “What’s the cost of asphalt per ton in my area?” The calculator answers these by combining your inputs with local material rates.

Input Fields Explained

- Length/Width: In feet (e.g., 50 ft x 10 ft).

- Thickness: In inches (residential projects often use 2-3 inches).

- Compaction Factor: 10-15% for most projects.

- Asphalt Density: Defaults to 145 lbs/ft³ (adjust for porous or cold mix).

Why Asphalt Tonnage Calculation is Important

Accurate asphalt tonnage calculations ensure you purchase the right amount of material, avoid overspending, and prevent project delays. Underestimating leads to costly last-minute orders, while overestimating wastes money on unused asphalt. Below, we outline typical requirements for roads and driveways:

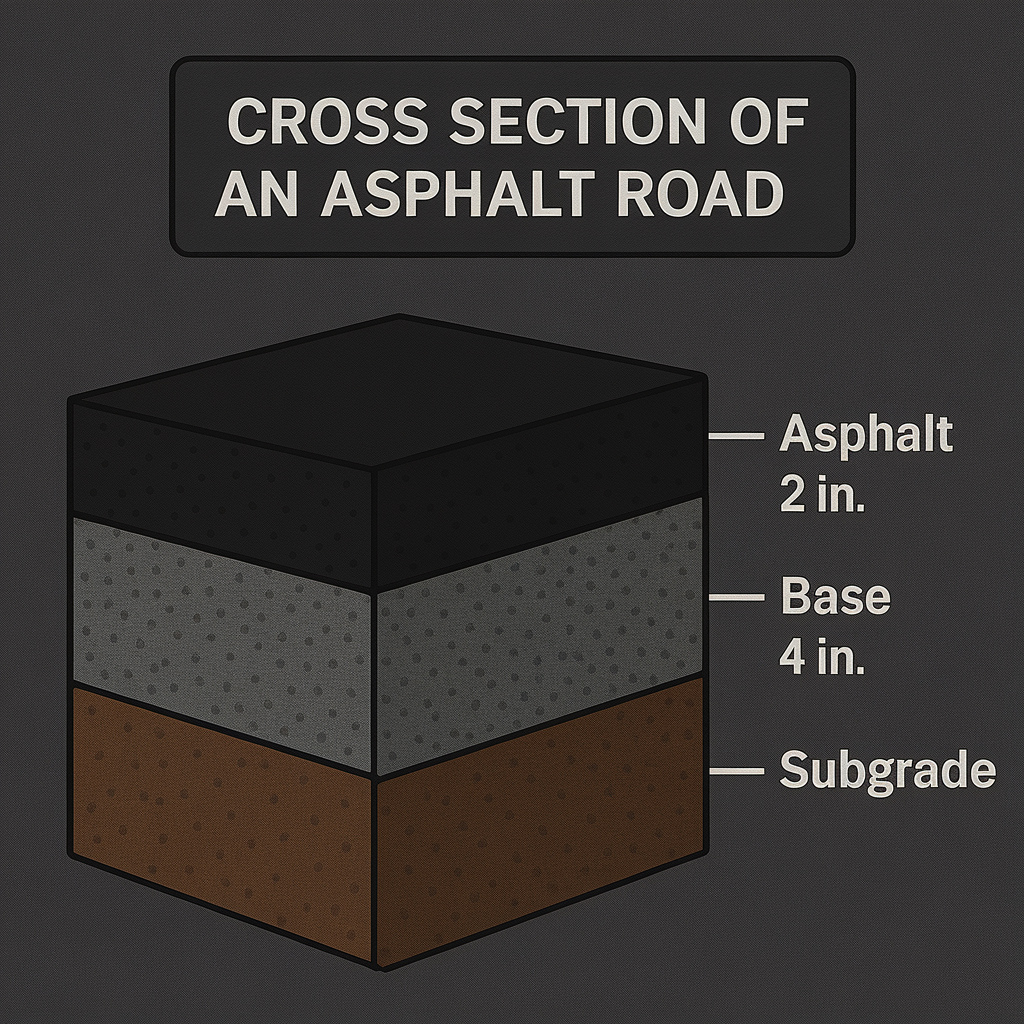

Typical Asphalt Road Construction

Roads require precise tonnage calculations due to their scale and durability needs:

- Thickness: Roads need 3-4 inches of compacted asphalt for light traffic, 6+ inches for highways.

- Density: Hot Mix Asphalt (HMA) is standard, with a density of ~145 lbs/cu ft.

- Example: A 1-mile road (5,280 ft long x 24 ft wide x 4 inches deep) requires ~3,800 tons of asphalt.

- Cost Impact: A 10% overestimation could waste $15,000+ on large projects.

Asphalt Driveway Projects

Driveways have different requirements but still benefit from accurate tonnage estimates:

- Thickness: Residential driveways use 2-3 inches of compacted asphalt.

- Material: HMA or recycled asphalt (10-15% lighter density).

- Example: A 20 ft x 50 ft driveway (3-inch depth) needs ~18 tons of asphalt.

- Budget Savings: Proper calculation prevents overordering for small sites.

Use our asphalt tonnage calculator to tailor estimates to your specific road or driveway project.

Common Asphalt Tonnage Calculation Mistakes

Avoid these errors to ensure accurate estimates and cost savings:

- Ignoring Compaction: Forgetting to add 10-15% extra asphalt for density changes during compaction.

- Using Average Density: Assuming all asphalt mixes weigh the same (e.g., porous vs. hot mix).

- Miscalculating Depth: Measuring depth in inches but using feet in formulas.

- Skipping Waste Allowance: Not adding 5-10% for trimming or errors.

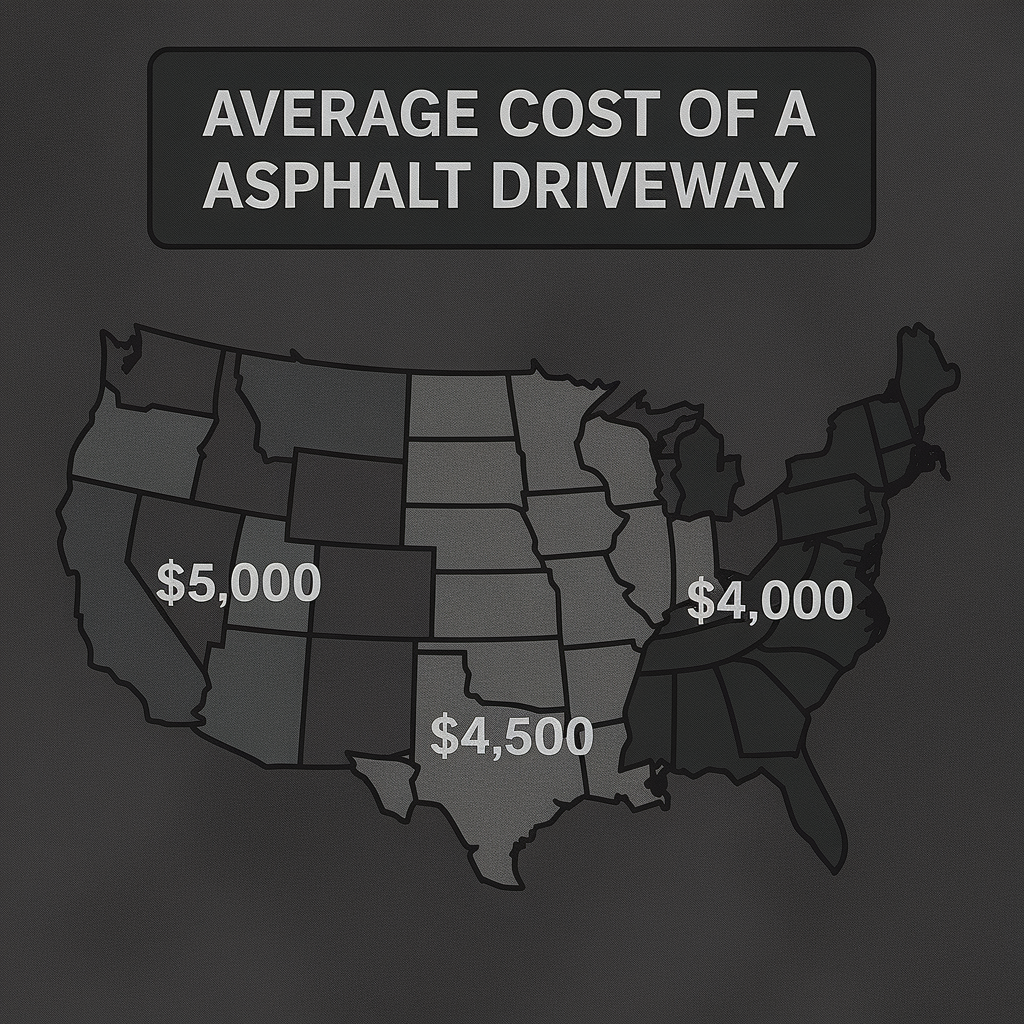

Asphalt Tonnage Costs: What to Expect

Understanding asphalt costs per ton helps you budget effectively. Prices vary based on location, project size, and market conditions:

Material Costs (Per Ton)

- Hot Mix Asphalt (HMA): $80–$150 per ton

- Recycled Asphalt (RAP): $25–$50 per ton

- Porous Asphalt: $100–$180 per ton

Prices fluctuate with oil prices and seasonal demand.

Additional Costs

- Labor: $3–$8 per sq. ft. (30-50% of total cost)

- Equipment: Compaction rollers, pavers ($200–$500/day)

- Base Preparation: Gravel sub-base adds $1.50–$3 per sq. ft.

Example Total Cost

A 1,000 sq. ft. driveway (3-inch depth, HMA):

- Asphalt Tonnage: ~12.5 tons × $120/ton = $1,500

- Labor & Equipment: $4,000–$6,000

- Total: $5,500–$7,500

Asphalt Tonnage FAQs

How Many Tons of Asphalt Do I Need Per Square Foot?

For 1 inch of compacted hot mix asphalt (145 lbs/cu ft):

Formula: (1 sq ft × 1/12 ft) × 145 lbs / 2000 = ~0.006 tons/sq ft.

Does Asphalt Density Vary by Region?

Yes! Warm climates often use denser mixes (e.g., HMA), while colder regions may opt for lighter polymer-modified asphalt.

Can I Reuse Leftover Asphalt?

Recycled asphalt (RAP) can be reused for base layers, saving 20-30% on material costs.

Benefits of Using Our Asphalt Tonnage Calculator

Our asphalt tonnage calculator provides several advantages for planning your paving project:

- Precise Material Estimates: Calculate exact tons needed for your project’s length, width, and depth, avoiding overpaying for excess asphalt.

- Cost Efficiency: Factor in compaction, waste, and asphalt type to minimize budget surprises.

- Regional Pricing Adjustments: The tool accounts for local asphalt prices and labor rates for accurate cost projections.

- Project-Specific Adjustments: Customize inputs for driveways, parking lots, or repairs to match your unique needs.

Tips for Reducing Asphalt Costs

Save money on your paving project with these strategies:

- Compare Material Quotes: Get pricing from multiple suppliers—bulk delivery often lowers per-ton rates.

- Time Your Project: Schedule paving in late spring/early fall (avoid winter) to prevent weather delays and price surges.

- Optimize Thickness: Use the calculator to determine the minimum depth required (e.g., 2-3 inches for driveways).

- Recycle Existing Asphalt: Crush and reuse old pavement for base layers, cutting material costs by 20-40%.

- Prepare the Site: Clear debris and grade the area yourself to reduce labor fees.

How to Find Reliable Asphalt Contractors

For quality results, partner with trusted professionals:

What to Look For

- Licensed & Insured: Verify credentials to avoid liability for accidents or subpar work.

- Experience with Project Size: Choose contractors familiar with residential, commercial, or municipal paving.

- Transparent Pricing: Request itemized quotes for materials, labor, and equipment.

- Positive Reviews: Check platforms like Google or BBB for consistent customer satisfaction.

Ask Before Hiring

- “Do you offer bulk delivery discounts for large projects?”

- “Can you provide a compaction guarantee for longevity?”

- “What’s the estimated timeline for my 2,000 sq. ft. driveway?”

References

Calculator based on:

- Roberts, F. L., Kandhal, P. S., Brown, E. R., Lee, D. Y., & Kennedy, T. W. (1996). Hot Mix Asphalt Materials, Mixture Design and Construction (2nd ed.). National Asphalt Pavement Association.

- Huang, Y. H. (2004). Pavement Analysis and Design (2nd ed.). Pearson Prentice Hall.

- Wallace, H. A., & Martin, J. R. (1967). Asphalt Pavement Engineering. McGraw-Hill Book Co.

Ready to start? Use our asphalt tonnage calculator to estimate materials, compare local contractor quotes, and plan your project with confidence. Whether it’s a small repair or a 10,000 sq. ft. parking lot, our tool ensures you’re equipped with accurate data to make cost-effective decisions.

Explore Our Asphalt Blog

Discover expert insights on asphalt types, construction techniques, maintenance best practices, and sustainable innovations for contractors, engineers, and property owners.

Asphalt Classification

Learn about different asphalt mixes and their applications for various climate conditions and traffic requirements.

Maintenance

Essential techniques to extend pavement lifespan through proper care and preventive treatments.

Engineering & Construction

Professional guidance on pavement design, subgrade preparation, and construction methodologies.

Sustainability

Environmentally friendly asphalt solutions and recycling technologies for modern paving projects.